Shop Services

Shop Services

This service is a standardized mechanical maintenance procedure for professional clipper machines.

What This Service Includes (Every Time)

Machine housing opened

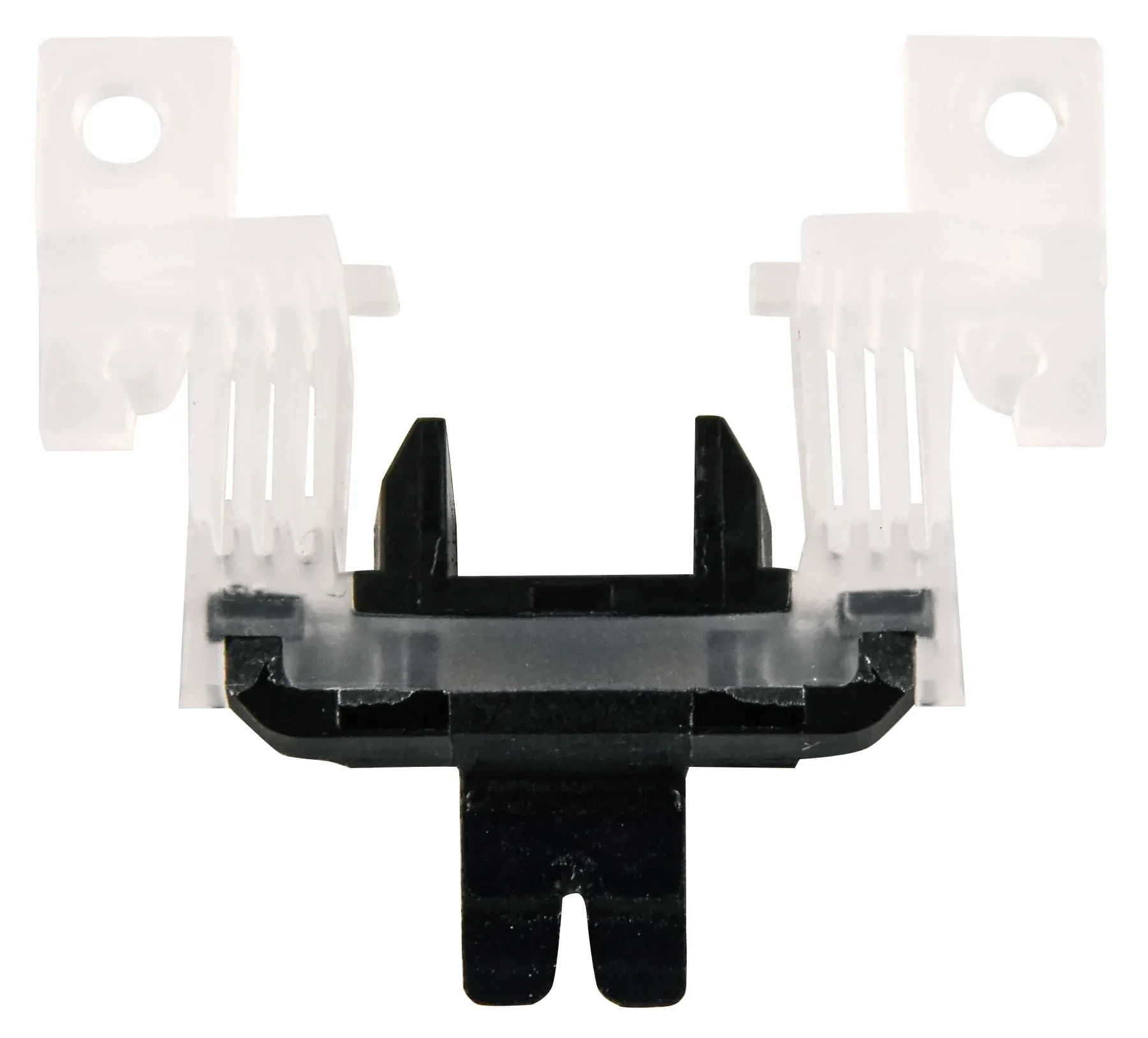

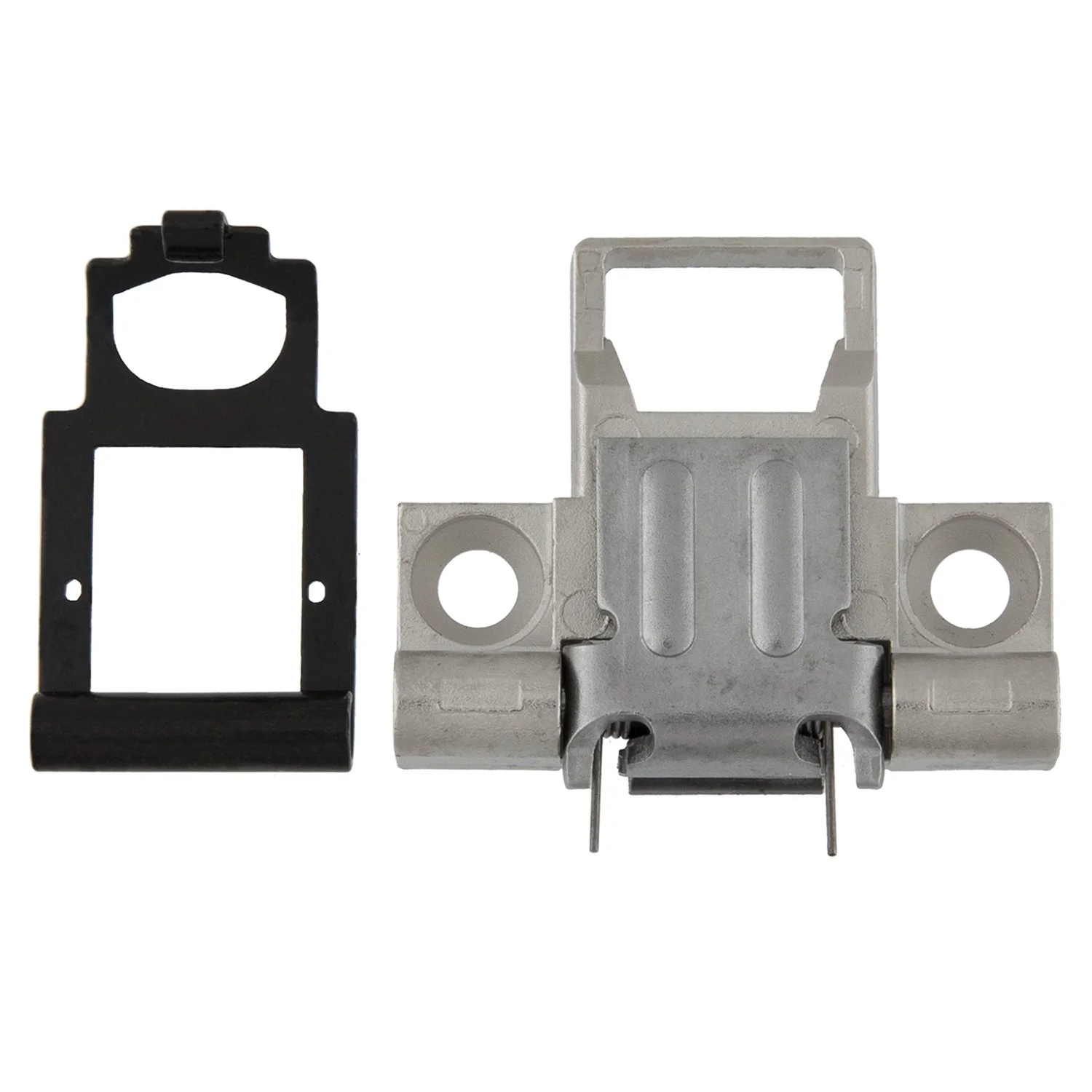

New blade drive installed (typical retail value ~$12)

New hinge installed (typical retail value ~$15–$20)

Proper reassembly and operational check

Every clipper receives a new blade drive and a new hinge. No exceptions. Ols parts may or may not be included in the return shipment.

What This Service Does Not Include

Nothing beyond reassembly

No motor, electrical, switch, or cord repair

No additional parts replaced unless explicitly authorized in advance

If parts are needed for an authorized repair, it could delay return times an additional 14 days.

If other issues are identified that require additional parts or labor, the customer will be contacted for approval before any work is performed.

In most cases, no additional work is required.

At times this may be used as a line item to bill for work performed on other brand clippers to perform other labor or parts.

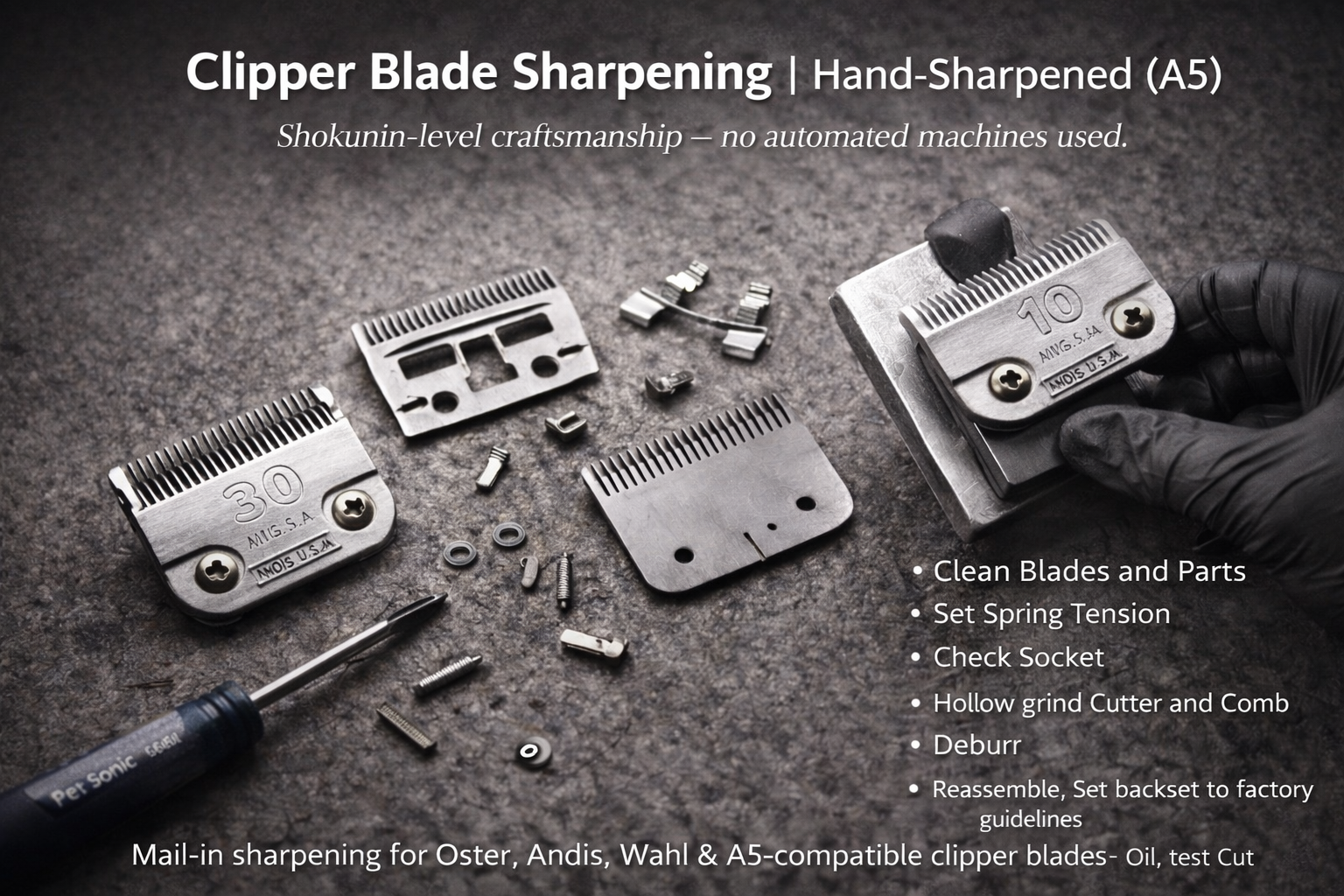

Professional Clipper Blade Sharpening – Hand-Finished Mail-In Service

This professional clipper blade sharpening service is built for dog groomers and veterinary clinics that require consistent cutting performance, correct blade geometry, and repeatable results. It supports professional clipper blade systems used in dog grooming, barbering, cosmetology, and veterinary applications.

Each clipper blade is sharpened individually by hand using documented, process-controlled methods. No automated feed machines, belt sharpeners, or batch grinding systems are used. This approach preserves proper cutter-to-comb interaction, restores factory edge geometry, and prevents premature wear commonly caused by mass-production sharpening.

All sharpening is performed at our Nevada City, California workshop and inspected prior to return.

Clipper Blades Covered by This Service

This service applies to standard professional grooming clipper blades, defined as:

Cutter and/or comb under 2 inches wide

Steel (non-ceramic) components

Professional A5 removable clipper blade systems

Compatible brands include Andis, Oster, Wahl, and equivalent professional clipper systems.

If inspection identifies worn or damaged components, required parts will be replaced as needed to restore proper blade function before return.

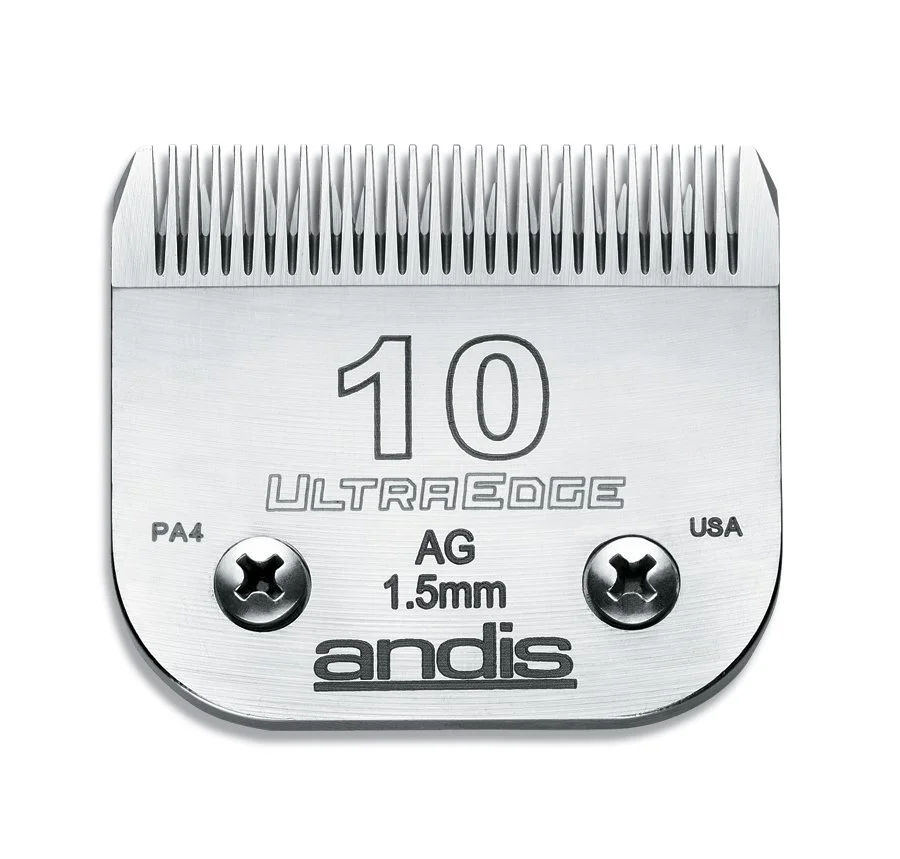

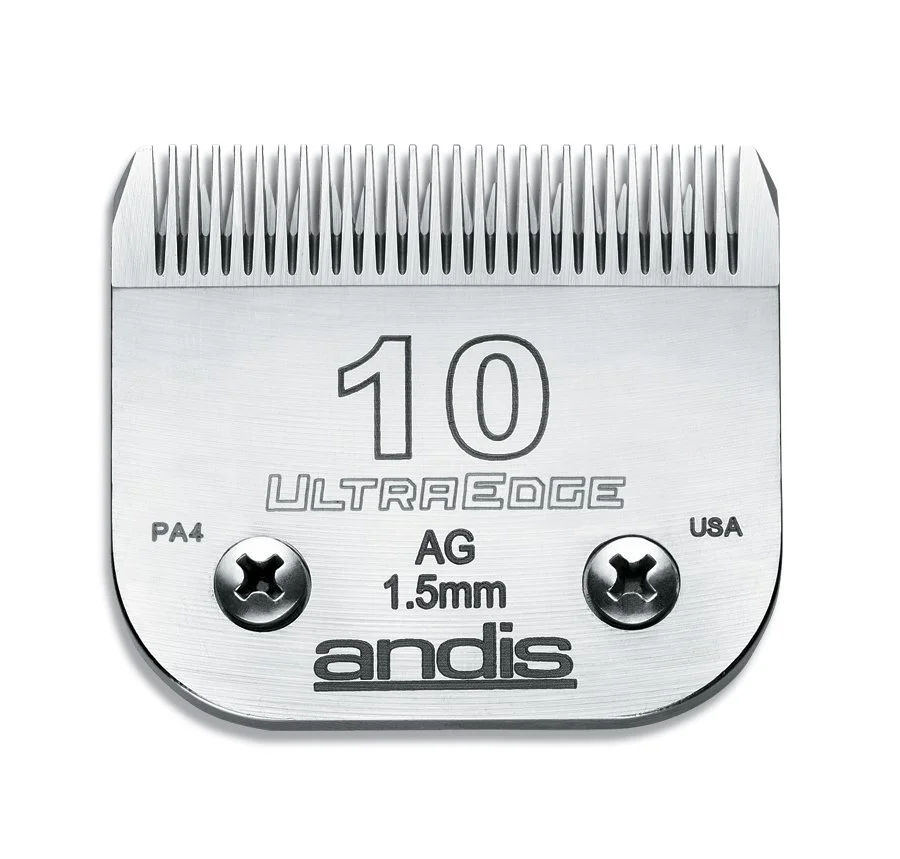

Images shown represent examples of clipper blades eligible for this service.

Professional Clipper Blade Sharpening Process

Each blade is serviced using a repeatable, inspection-driven process:

Complete blade disassembly

Ultrasonic and manual cleaning of all components

Spring tension evaluation and adjustment

Socket and wear-surface inspection

Hollow grinding of cutter and comb to restore factory geometry

Precision deburring and edge refinement

Reassembly and factory backset adjustment

Proper lubrication

Final test cutting to verify smooth, consistent performance

This process is designed to deliver reliable cutting performance, extended blade life, and predictable results for professional use.

Quality Control & Turnaround

48-hour shop turnaround after receipt

Ships to all 50 U.S. states

Inspection-verified sharpening

14-day performance guarantee

Who This Service Is For

Professional dog groomers

Barbers using detachable clipper blade systems

Cosmetologists and stylists using A5-style clipper blades

Mobile grooming and barber businesses

Veterinary clinics and animal care facilities

Shops requiring repeatable, accountable clipper blade sharpening

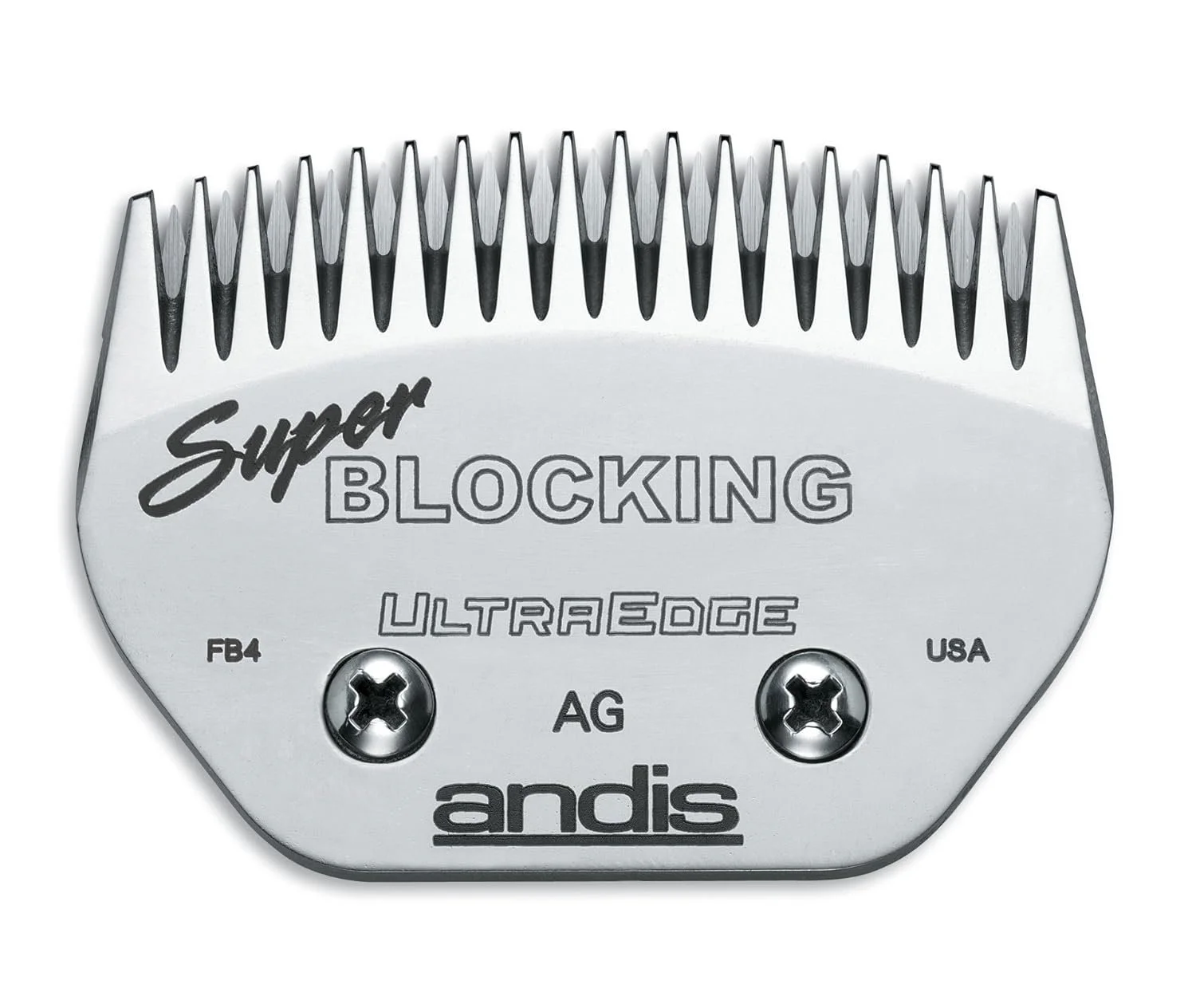

Wide Clipper Blade Sharpening – Precision-Controlled Mail-In Service

This wide clipper blade sharpening service is designed for professional groomers and veterinary clinics using wide A5 clipper blades that require precise geometry control across an extended cutting surface.

Wide blades place greater demands on sharpening accuracy due to increased surface area and engagement length. Each blade is sharpened individually with full manual control using documented, inspection-driven methods. No automated feed machines, belt sharpeners, or batch grinding systems are used. This ensures even pressure, correct cutter-to-comb alignment, and consistent cutting performance across the full blade width.

All sharpening is performed at our Nevada City, California workshop and inspected prior to return.

Wide Clipper Blades Covered by This Service

This service applies to wide professional grooming clipper blades, defined as:

Cutter and/or comb over 2 inches wide

Steel (non-ceramic) components

Professional wide A5 removable clipper blade systems

Compatible brands include Andis, Oster, Wahl, and equivalent professional clipper systems.

If inspection identifies worn or damaged components, required parts will be replaced as needed to restore proper blade function before return.

Images shown represent examples of wide clipper blades eligible for this service.

Wide Clipper Blade Sharpening Process

Each wide blade is serviced using a repeatable, inspection-driven process designed to manage increased blade surface area:

Complete blade disassembly

Ultrasonic and manual cleaning of all components

Spring tension evaluation and adjustment

Socket and wear-surface inspection

Precision hollow grinding of cutter and comb to restore factory geometry

Careful deburring to ensure smooth cutter-to-comb engagement

Reassembly and factory backset adjustment

Proper lubrication

Final test cutting to verify smooth, even performance across the full cutting width

This process is designed to deliver uniform cutting performance, extended blade life, and predictable results for wide-format clipper blades.

Quality Control & Turnaround

48-hour shop turnaround after receipt

Ships to all 50 U.S. states

Inspection-verified sharpening

14-day performance guarantee

Who This Service Is For

Professional dog groomers using wide blades

Mobile grooming businesses

Veterinary clinics

High-volume grooming salons

Shops requiring repeatable, accountable sharpening for wide clipper blades

This service is for 5-in-1 adjustable clipper blades, commonly used for detail work, finishing, and close-cut applications. These blades differ significantly from standard clipper blades and require controlled handling due to their compact construction and integrated adjustment mechanisms.

We service Wahl 5-in-1 blades as well as compatible 5-in-1 designs from other manufacturers, provided the blade is mechanically sound and within safe service limits. Each blade is inspected before sharpening to determine suitability.

Sharpening focuses on restoring cutting efficiency while maintaining proper blade alignment and function. Because 5-in-1 blades use thinner cutting surfaces and tighter tolerances, not all blades are eligible for service.

WHAT’S INCLUDED

Professional inspection prior to sharpening

Precision sharpening appropriate for 5-in-1 blade geometry

Cleaning and functional testing

Return shipping included with mail-in orders

IMPORTANT LIMITATIONS (THIS PART IS CRITICAL)

Not all 5-in-1 blades can be safely sharpened.

The following blades may be declined or returned unserviced:

Blades with excessive wear or thinning

Blades with damaged adjustment mechanisms

Blades that have been previously over-sharpened

Blades that no longer meet safe cutting tolerances

If a blade is not serviceable, you will be contacted before any work is performed.

TURNAROUND

Typical turnaround is defined by the Mail-In Sharpening system and depends on volume and condition. Transit time is not included.

HOW TO SEND YOUR BLADES

Secure blades to prevent movement during shipping

Include your contact information in the package

Add this service to your Mail-In Sharpening order

Ship using your preferred carrier

WHO THIS SERVICE IS FOR

Professional groomers

Mobile grooming operations

Detail and finishing work requiring adjustable blades

WHO THIS SERVICE IS NOT FOR

Severely worn or damaged blades

Cosmetic restoration requests

This service is intended for professionals who understand the limitations of 5-in-1 blades and want careful, condition-based sharpening rather than aggressive material removal.

This service is for large animal clipper blades used on horses, cattle, livestock, and other heavy-coat animals. These blades are manufactured from thicker steel and designed to operate under higher torque loads than standard grooming or salon clipper blades.

Large animal blades require a different sharpening approach than small grooming blades. Proper service focuses on restoring cutting efficiency while maintaining edge durability and heat resistance suitable for extended use and dense coats.

Each blade is inspected prior to sharpening to confirm it is mechanically sound and within safe service limits. Blades that cannot be safely serviced will be identified before work proceeds.

WHAT’S INCLUDED

Pre-service inspection

Professional sharpening appropriate for heavy-duty blade geometry

Cleaning and functional testing

Return shipping included with mail-in orders

IMPORTANT LIMITATIONS

Not all large animal clipper blades are serviceable.

The following may be declined or returned unserviced:

Blades with excessive thinning or deep structural damage

Blades with broken teeth or severe corrosion

Blades previously overheated or improperly ground

Blades outside safe cutting tolerances

If a blade is not suitable for sharpening, you will be contacted before any work is performed.

TURNAROUND

Turnaround time is defined by the Mail-In Sharpening system and depends on condition and order volume. Shipping transit time is not included.

HOW TO SEND YOUR BLADES

Secure blades to prevent movement during shipping

Remove loose hair, debris, or excessive buildup if possible

Include your contact information in the package

Add this service to your Mail-In Sharpening order

Ship using your preferred carrier

WHO THIS SERVICE IS FOR

Equine professionals

Livestock handlers

Mobile large-animal grooming services

Agricultural and ranch operations

Equine · Livestock · Heavy-Duty Clipper Blades

Oster-Andis-Wahl

WHO THIS SERVICE IS NOT FOR

Standard grooming clipper blades

5-in-1 adjustable blades

Cosmetic restoration or display blades

Those are a different Line Item

This service prioritizes durability, safety, and consistent cutting performance for demanding large-animal environments.

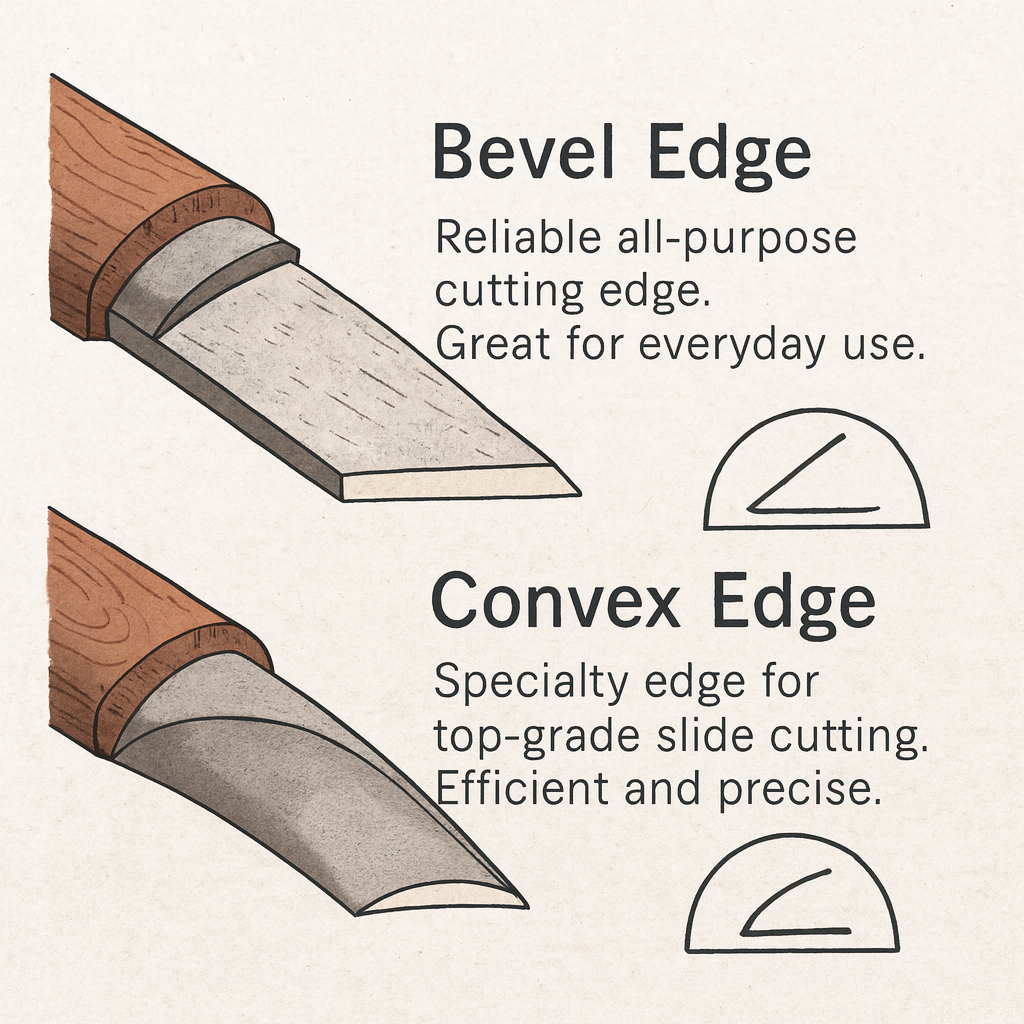

Professional Beveled Shear Sharpening for Dog Groomers – Mail-In Service

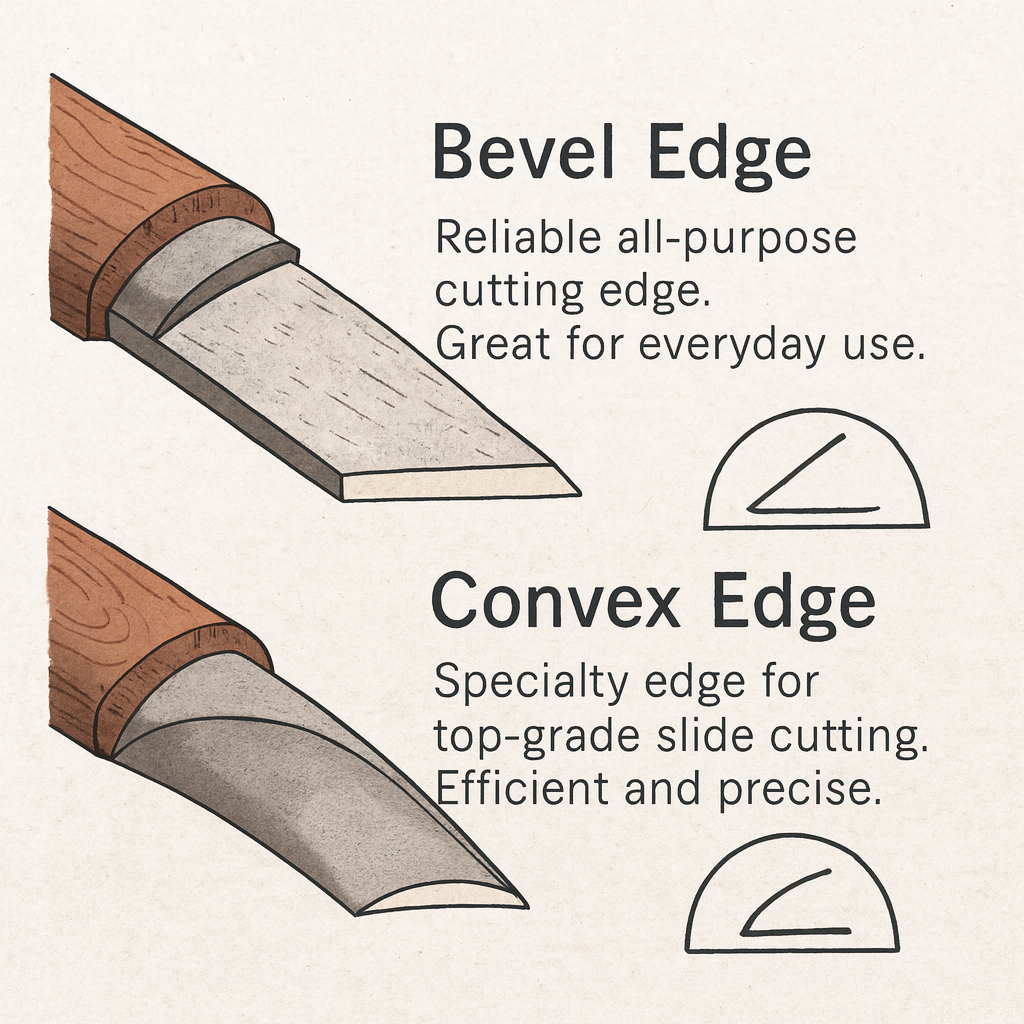

This Professional Beveled Shear Sharpening service is designed for everyday working dog grooming shears with a beveled (German-style) edge. It applies to straight or curved grooming shears of any length, including thinners and chunker/texturizer shears used in high-volume grooming environments.

Basic Beveled Sharpening is ideal for reliable, professional grooming tools that require consistent cutting performance, proper mechanical setup, and dependable results, without the extended time or edge refinement required for convex or premium shear services.

All work is performed using repeatable, inspection-driven methods focused on function, longevity, and safe daily use.

Dog Grooming Shears Covered by This Service

This service applies to:

Beveled (German-style) grooming shears

Straight or curved grooming shears

Thinning shears

Chunker / texturizer shears

Designed specifically for dog grooming tools, not barber or cosmetology shears.

Basic Beveled Shear Sharpening Process

Each shear is serviced using a proven, repeatable process focused on function and consistency:

Complete shear disassembly

Thorough cleaning of all components

Detailed inspection of edge, pivot, and hardware

Replacement of worn washers or hardware as needed

Topside sharpening on a flat hone to restore the original factory bevel edge (unless otherwise specified)

Re-establishment of the factory ridgeline (inside face), when applicable

Reassembly

Proper tension setting

Final test cutting with no lateral pressure (no thumb or finger bias)

This process delivers clean cutting action, mechanical reliability, and consistent performance for daily grooming work.

Turnaround & Quality Control

48-hour shop turnaround after receipt

Ships to all 50 U.S. states

Inspection-verified sharpening

14-day performance guarantee

Who This Service Is For

Professional dog groomers

Mobile grooming businesses

High-volume grooming salons

Groomers needing reliable daily-use sharpening without premium pricing

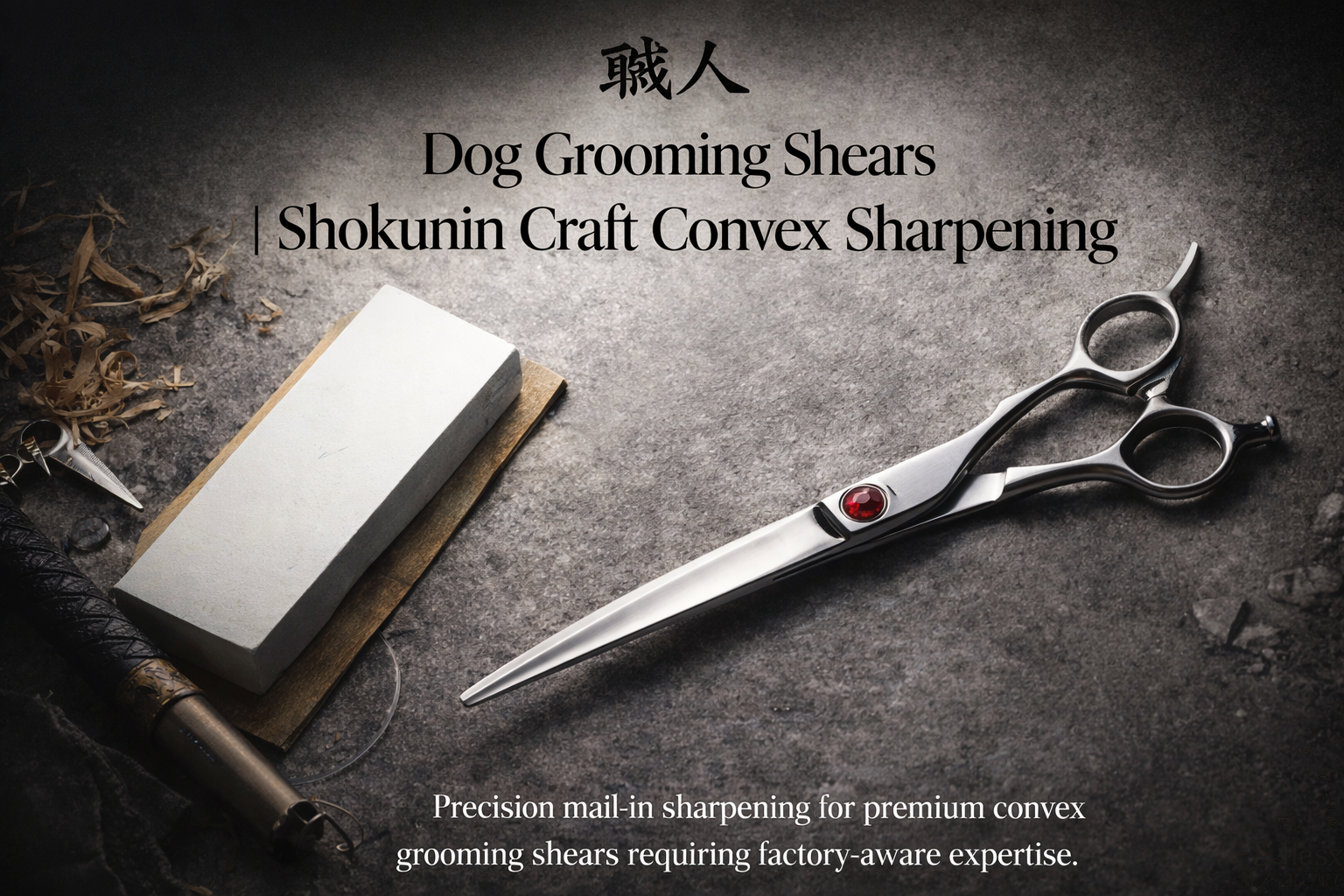

Premium Convex Grooming Shear Sharpening for Professional Dog Groomers

This Premium Convex Grooming Shear Sharpening service is designed for high-end, name-brand convex grooming shears used by professional dog groomers who require maximum cutting performance, precise edge geometry, and strict mechanical accuracy.

This service applies to straight or curved convex grooming shears of any length, including premium thinning and texturizing shears, typically valued in the $300+ range and manufactured with factory-specific convex edge profiles.

Unlike basic beveled sharpening, premium convex shears require a sharpener capable of accurately identifying original factory geometry, intended cutting application, and dynamic shear behavior. This service uses inspection-driven, process-controlled methods to restore performance without altering the shear’s designed cutting characteristics.

If you own a small number of high-value grooming shears and do not want them sharpened like everyday working tools, this is the correct service level.

Typical turnaround: 1–3 weeks

Premium Grooming Shears Covered by This Service

This service is intended for professional convex grooming shears, including:

Straight convex grooming shears

Curved convex grooming shears

Premium thinning shears

High-end chunker / texturizer grooming shears

Designed specifically for dog grooming shears, not barber or cosmetology shears.

Common Premium Brands Serviced (Not Limited To)

Utsumi

Above

Green Mouse (PIO)

Dream

Top-tier Kenchii lines

Other premium Japanese, Korean, or high-end Chinese grooming shear manufacturers

Brand listing is representative — factory geometry is identified per shear, not assumed by brand.

Premium Convex Sharpening Process

Each shear is individually evaluated and serviced using a disciplined, factory-aware process designed for convex edge preservation:

Complete shear disassembly

Thorough cleaning of all components

Detailed inspection of edge geometry, pivot condition, and hardware

Replacement of worn washers or hardware as required

Precision convex edge sharpening to restore original factory angle (unless otherwise specified)

Re-establishment of the factory ridgeline (inside face), when applicable

Reassembly

Precision tension setting

Final test cutting with no lateral pressure (no thumb or finger bias)

This process prioritizes cut quality, edge longevity, and mechanical reliability, not speed.

Turnaround & Quality Control

1–3 week turnaround depending on shear condition and workload

Inspection-verified sharpening

Mechanical setup verified before return

14-day performance guarantee

Who This Service Is For

Professional dog groomers using premium convex shears

Groomers with high-value, brand-specific grooming tools

Shops requiring maximum precision and controlled results, not volume sharpening

Premium Convex Sharpening for Professional Barbers & Cosmetologists

This Premium Convex Barber & Beauty Shear Sharpening service is designed for high-precision barber and cosmetology shears manufactured with true convex (Japanese-style) edge geometry. It applies to straight or curved convex shears of any length, typically valued in the $400+ range and produced with brand-specific factory tolerances.

Unlike standard or volume sharpening, premium barber and beauty shears require exact identification of original factory geometry, cutting intent, and dynamic edge behavior. This service uses inspection-driven, process-controlled methods to restore cutting performance without altering or generalizing the original design.

If you own a select set of high-end barber or cosmetology shears and do not want them serviced the same way as everyday working tools, this is the correct sharpening tier.

Typical turnaround: 1–3 weeks

Barber & Beauty Shears Covered by This Service

This service is intended for professional convex barber and cosmetology shears, including:

Straight convex barber shears

Curved convex barber shears

High-end cosmetology cutting shears

Premium thinning and texturizing shears

This service is not intended for dog grooming shears.

Certification & Brand-Aware Expertise

Sharpening is performed by a Mizutani-certified sharpener, ensuring factory-aware handling of high-end Japanese convex shears and equivalent premium tools.

Common brands serviced include (not limited to):

Mizutani

Utsumi

Above

Green Mouse (PIO)

Dream

Top-tier Kenchii models

Other premium Japanese, Korean, and high-end Chinese barber and cosmetology shear manufacturers

Brand listings are representative.

Each shear is evaluated individually — factory geometry is identified, not assumed.

Premium Convex Sharpening Process

Each shear is serviced using a disciplined, factory-conscious process designed for precision and risk control:

Complete shear disassembly

Thorough cleaning of all components

Detailed inspection of edge geometry, pivot condition, and hardware

Replacement of worn washers or hardware as required

Precision convex sharpening to restore original factory angles (unless otherwise specified)

Re-establishment of the factory ridgeline (inside face), when applicable

Reassembly

Precision tension setting

Final test cutting with no lateral pressure (no thumb or finger bias)

This process prioritizes cut accuracy, edge longevity, and mechanical integrity over speed.

Turnaround & Quality Control

1–3 week turnaround depending on shear condition and workload

Inspection-verified sharpening

Mechanical setup verified before return

14-day performance guarantee

Who This Service Is For

Professional barbers using premium convex shears

Cosmetologists working with high-end, brand-specific tools

Professionals who require factory-accurate results, not generalized sharpening

Authorized Mizutani Sharpening by a Certified Specialist

This Mizutani Authorized Sharpening service is designed exclusively for Mizutani professional shears and is performed by a Mizutani-certified sharpener following factory-aware methods and specifications.

Mizutani shears are manufactured with brand-specific convex geometry, steel treatment, and cutting dynamics that require more than standard premium sharpening. This service focuses on accurate restoration of original factory geometry, controlled edge refinement, and verified mechanical setup — without altering the shear’s intended performance.

This is the correct service level for owners who require authorized, warranty-respecting work and do not want their Mizutani shears treated like general convex tools.

Who This Service Is For

This service is intended for:

Professional barbers using Mizutani shears

Professional hair stylists and cosmetologists using Mizutani shears

Owners who require authorized, factory-aware sharpening

This service applies only to Mizutani shears.

What This Authorized Service Includes

Authorized Mizutani sharpening performed by a certified sharpener

Restoration of original factory convex geometry

Controlled edge refinement and finishing appropriate to the specific model

Proper hinge service, tension setting, and reassembly

Full cleaning and inspection of each shear

Verification for chips, burrs, alignment issues, and mechanical integrity

Clear service notes outlining work performed and any recommended repairs

All work is performed using inspection-driven, process-controlled methods — not automated or generalized sharpening systems.

Turnaround Options

Standard turnaround: 3–5 business days after receipt

Priority service: Available when scheduled in advance

If additional repairs are required, you will be contacted before work proceeds.

Why Use Battle Born Blade Sharpening for Mizutani

Mizutani-certified sharpener

Factory-aware sharpening aligned to Mizutani specifications

Inspection-based process control for consistency and risk reduction

Transparent communication and documented service notes

Trusted by professionals across grooming, barbering, and cosmetology

This service prioritizes accuracy, accountability, and repeatable results over speed or volume.

How to Send Your Mizutani Shears

Pack shears securely and include contact information

Note any service preferences or concerns

Indicate standard or priority turnaround

Ship to Battle Born Blade Sharpening

You will be contacted if any additional repair work is recommended prior to completion.

Price

$60.00 per Mizutani shear

(Authorized factory-aware sharpening · mail-in service)

Additional repairs (pivot work, deep chip removal, recoating) are quoted after inspection.

Ready to Restore Mizutani Performance?

Ship or bring your Mizutani shears to Battle Born Blade Sharpening for authorized, factory-aware service performed with precision and accountability.

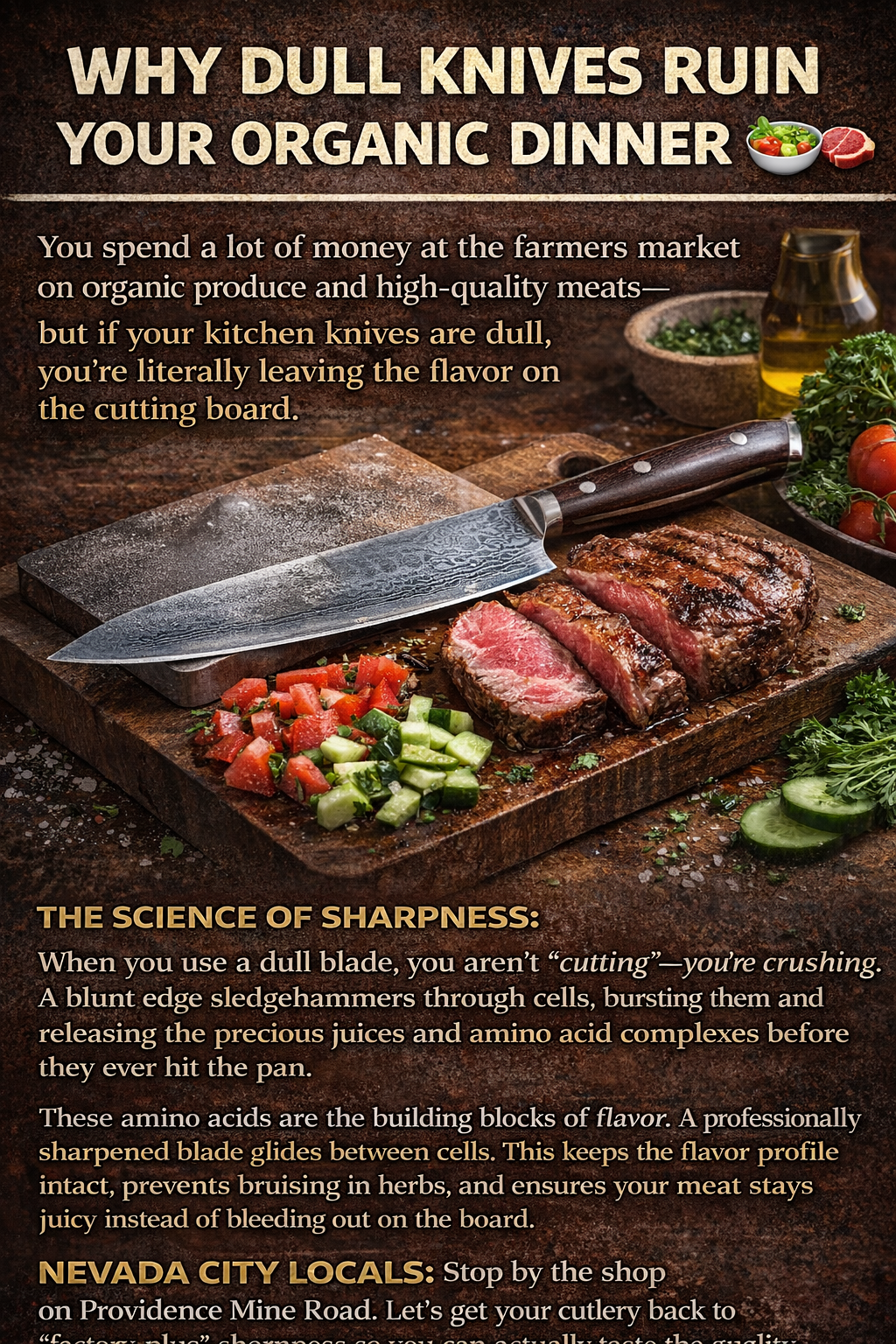

Professional cutlery sharpening is not about making a knife “razor sharp” in isolation. True performance comes from edge geometry, steel behavior, and micron-level finishing working together. Our Mail-In Cutlery Sharpening service is designed for cooks, chefs, and serious home users who understand that a knife’s job is not to crush food—but to separate cells cleanly and efficiently.

Why Sharpness Alone Is Not Enough

A blade can feel sharp and still perform poorly. If the knife is too thick behind the edge, it wedges into food, tearing fibers and rupturing cells. This causes herbs to bruise, vegetables to oxidize faster, and proteins to lose moisture before they ever reach the pan.

Proper sharpening restores:

Correct edge geometry for effortless slicing

Thin, consistent bevels that reduce wedging

Low-friction surfaces that preserve texture and flavor

A clean slice preserves juices, amino acids, and aromatics—fundamental components of taste.

The Science of Clean Cutting

When a knife is sharpened correctly, it glides between cells rather than smashing through them. This minimizes:

Cellular rupture

Premature juice loss

Flavor degradation

This is why professionally sharpened knives don’t just feel better—they cook better.

Steel Matters: From Iron Sand to Modern Kitchen Knives

Many high-end kitchen knives trace their lineage to traditional steelmaking methods that began with iron sand (satetsu) gathered from riverbeds and coastal regions. Through high-temperature smelting and careful carbon control, this process produced ultra-pure steel with exceptional edge potential.

Modern high-carbon kitchen steels—especially those used in premium Japanese cutlery—inherit this philosophy:

clean steel + controlled hardness + refined geometry = superior cutting performance.

Micron-Level Finishing & Deburring

After shaping the edge on precision stones, the final performance of a knife depends on deburring and polishing at the microscopic level.

We finish edges using ultra-fine abrasives (often in the sub-micron range) to:

Remove the wire edge cleanly

Polish the apex for reduced drag

Increase edge stability and longevity

This final step is what creates that effortless, “scary sharp” feel—where a blade slices with minimal pressure and maximum control.

A Rhythm of Care, Not a One-Time Fix

Knives are precision tools, not disposable objects. Regular honing maintains alignment, but periodic professional sharpening is required to restore geometry, thin the edge, and reset performance. Our mail-in service supports this long-term rhythm of care.

Mail-In Sharpening, Done Right

1–3 Day Turnaround (after receipt)

Geometry-correct sharpening (not grinder damage)

Secure return shipping

Suitable for Western and Japanese kitchen knives

Ship your knives to professionals who understand steel, structure, and cutting physics—not just sharpness for sharpness’ sake.

Restore your cutlery to factory-plus performance and taste the difference precision makes.

1-on-1 Sharpening Training & Consultation

Half-Day Private Session (3–5 Hours)

$500

This private sharpening consultation is a focused, one-on-one training and technical evaluation session for individuals seeking to learn professional sharpening as a disciplined craft.

The purpose of this session is education, orientation, and technical clarity—not certification, not equipment sales, and not mass instruction. It functions as an entry point into formal sharpening training, allowing serious students to understand the mechanics, standards, and realities of the trade before committing to deeper instruction or larger investments.

All authority, lineage, and professional standards governing this work are documented in the Battle Born Blade Sharpening – About page. This consultation applies those standards directly to your tools, questions, and goals.

This consultation is the required starting point for individuals considering advanced sharpening training through Battle Born Blade Sharpening.