Image 1 of 7

Image 1 of 7

Image 2 of 7

Image 2 of 7

Image 3 of 7

Image 3 of 7

Image 4 of 7

Image 4 of 7

Image 5 of 7

Image 5 of 7

Image 6 of 7

Image 6 of 7

Image 7 of 7

Image 7 of 7

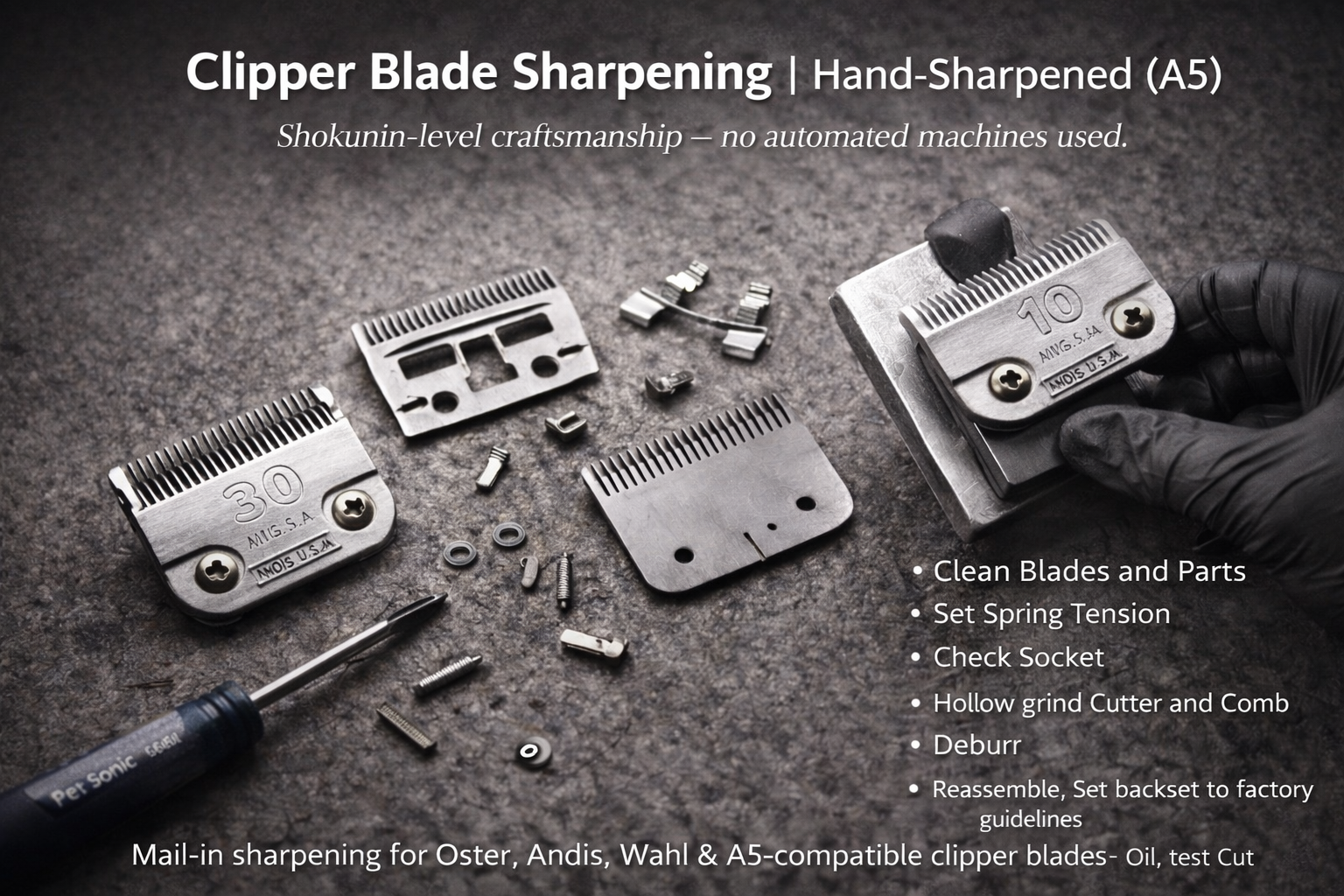

Clipper Blade Sharpening

Professional Clipper Blade Sharpening – Hand-Finished Mail-In Service

This professional clipper blade sharpening service is built for dog groomers and veterinary clinics that require consistent cutting performance, correct blade geometry, and repeatable results. It supports professional clipper blade systems used in dog grooming, barbering, cosmetology, and veterinary applications.

Each clipper blade is sharpened individually by hand using documented, process-controlled methods. No automated feed machines, belt sharpeners, or batch grinding systems are used. This approach preserves proper cutter-to-comb interaction, restores factory edge geometry, and prevents premature wear commonly caused by mass-production sharpening.

All sharpening is performed at our Nevada City, California workshop and inspected prior to return.

Clipper Blades Covered by This Service

This service applies to standard professional grooming clipper blades, defined as:

Cutter and/or comb under 2 inches wide

Steel (non-ceramic) components

Professional A5 removable clipper blade systems

Compatible brands include Andis, Oster, Wahl, and equivalent professional clipper systems.

If inspection identifies worn or damaged components, required parts will be replaced as needed to restore proper blade function before return.

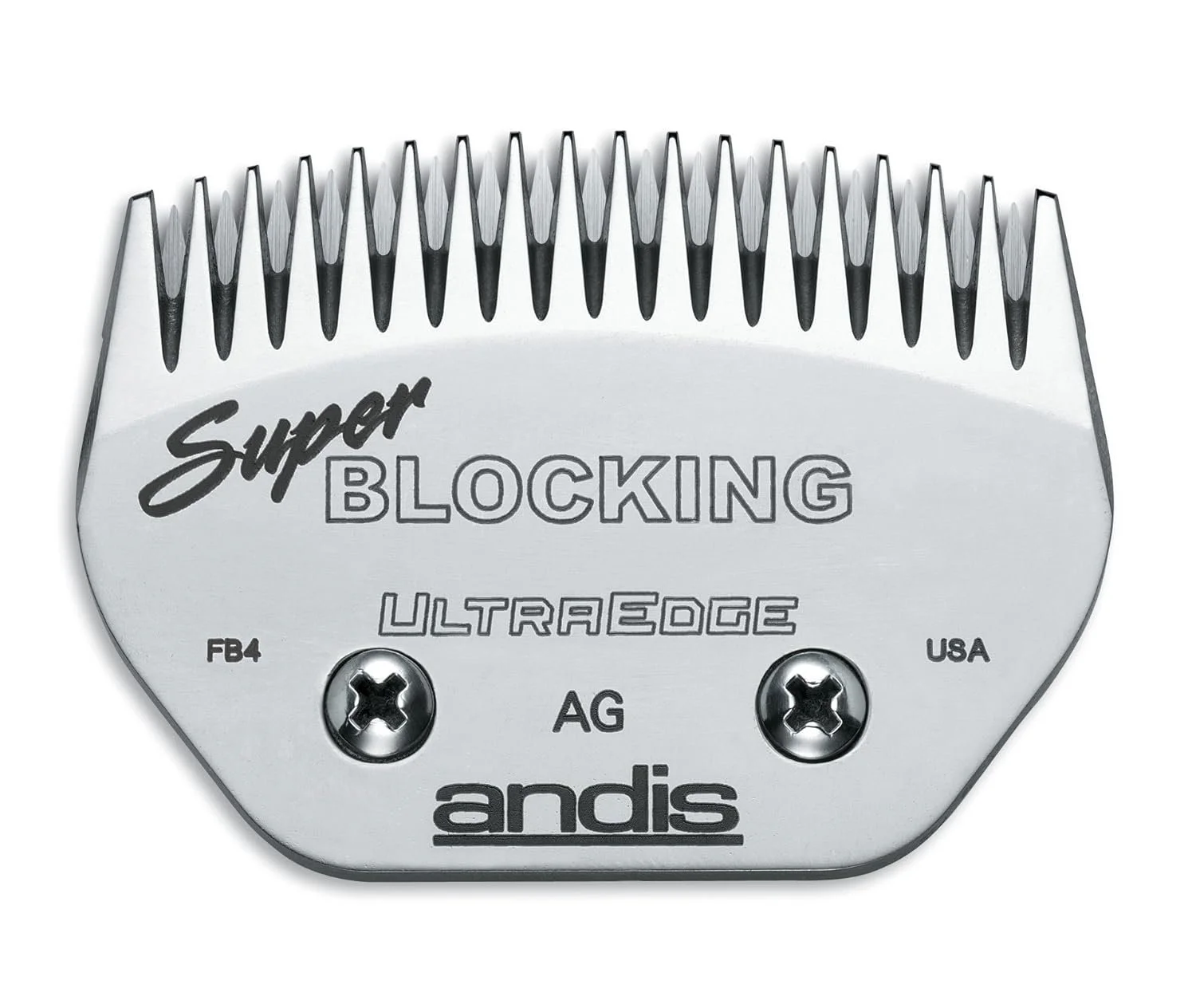

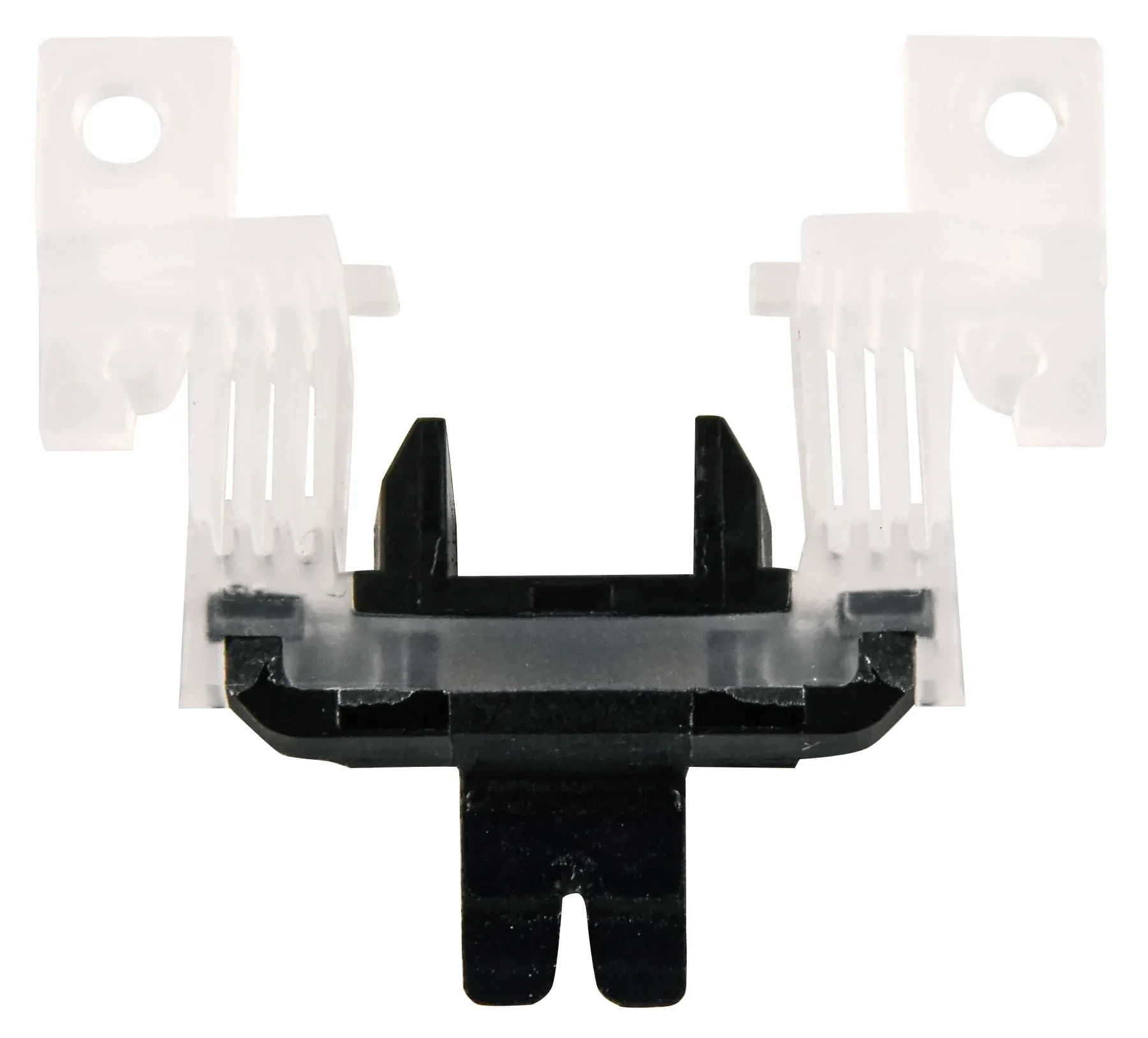

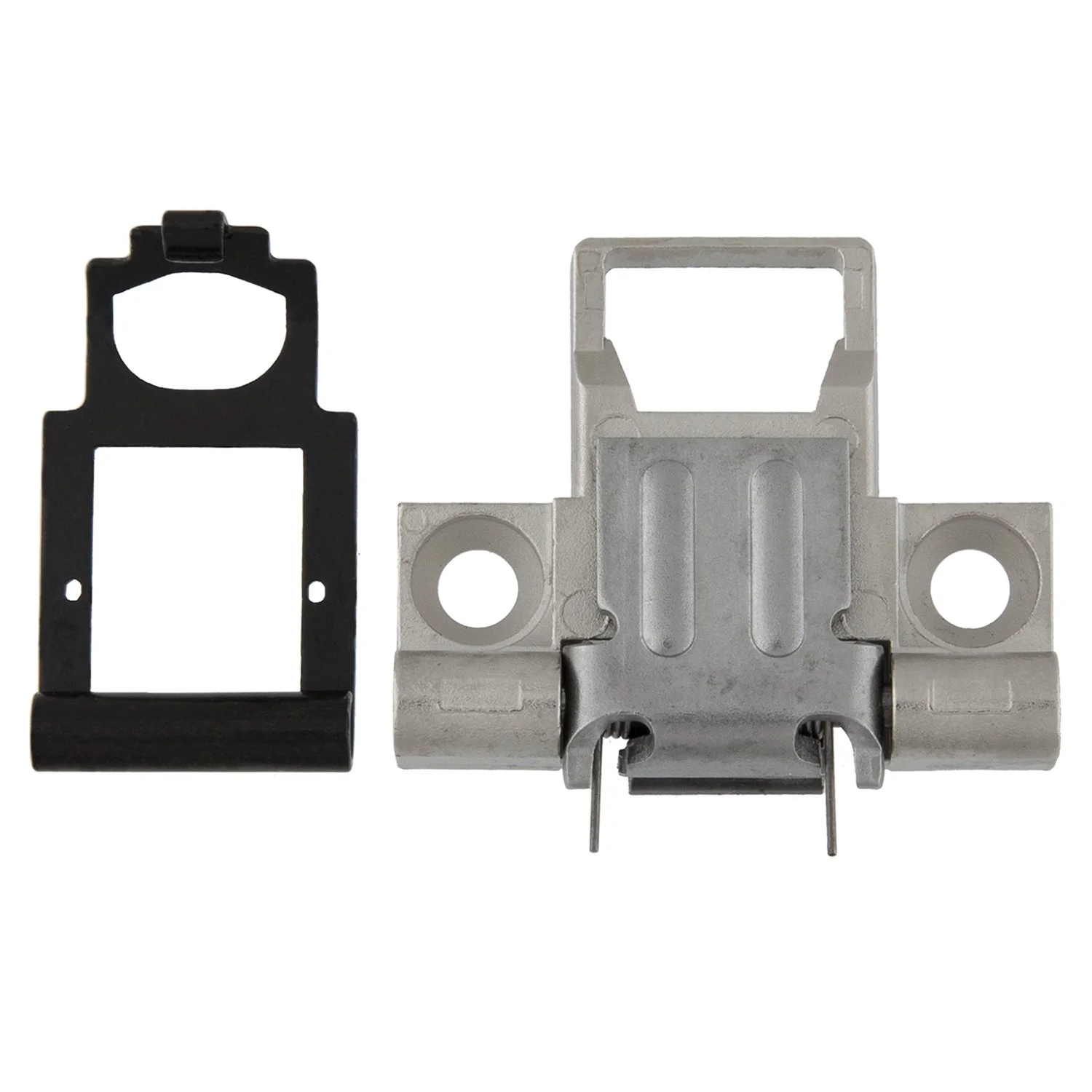

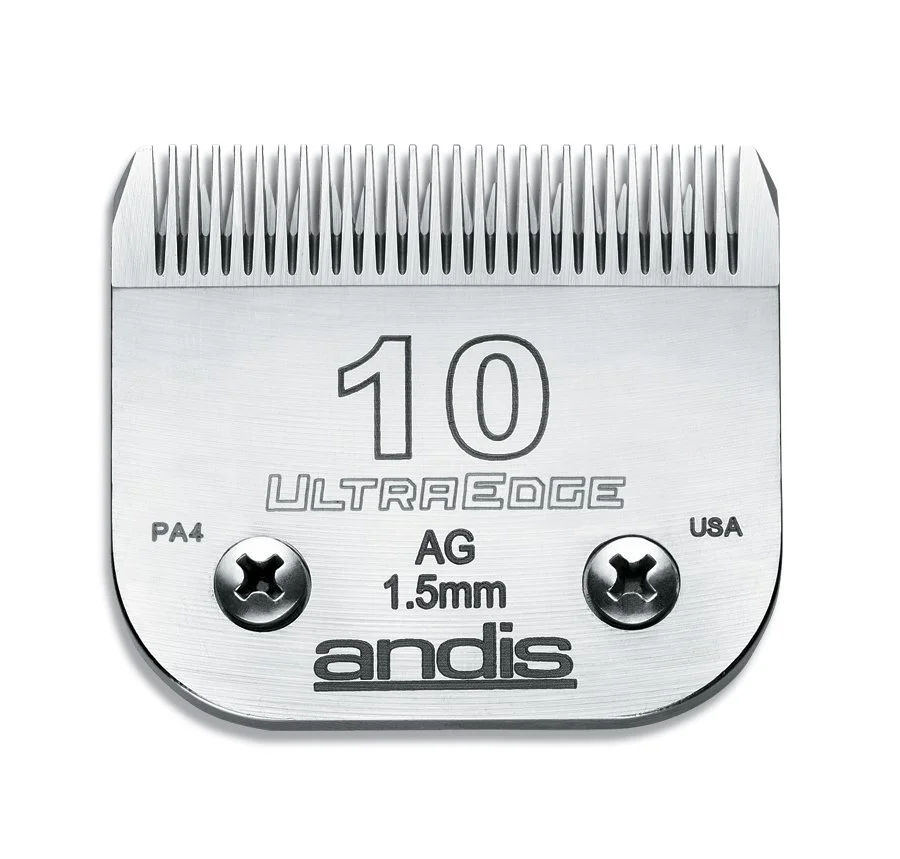

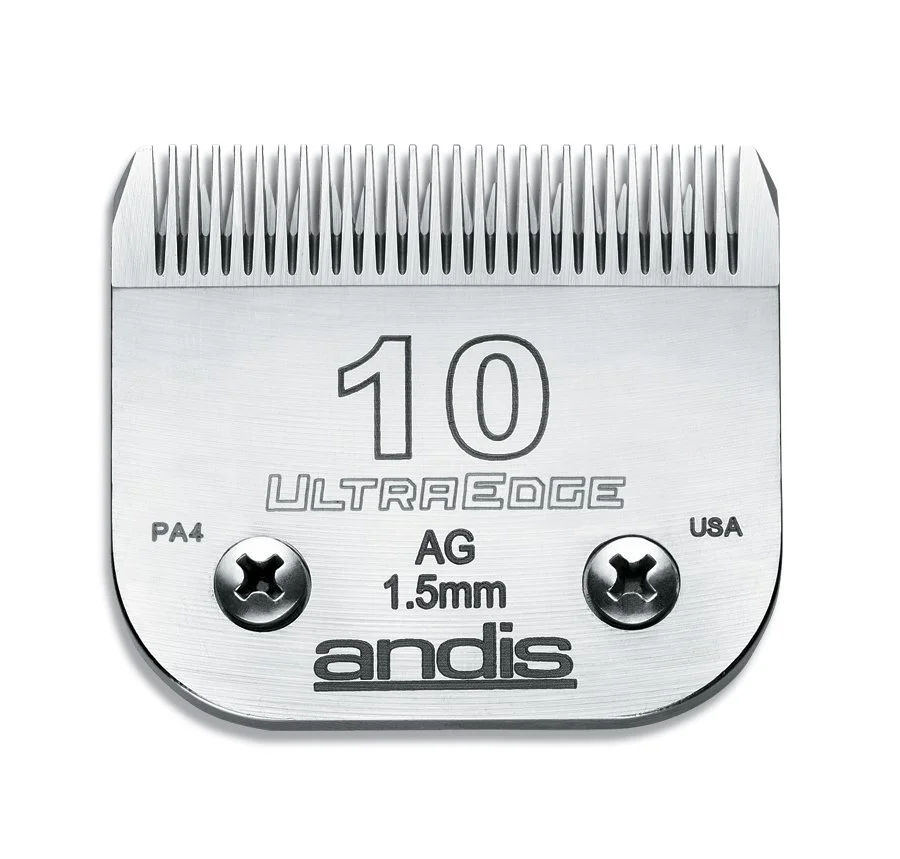

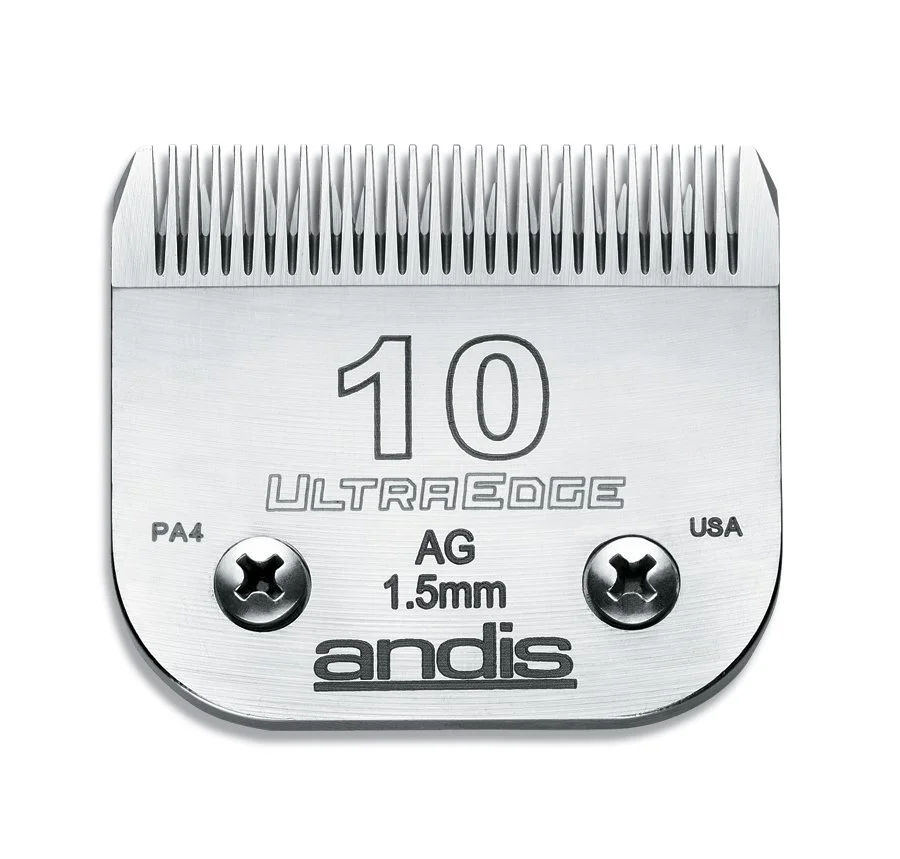

Images shown represent examples of clipper blades eligible for this service.

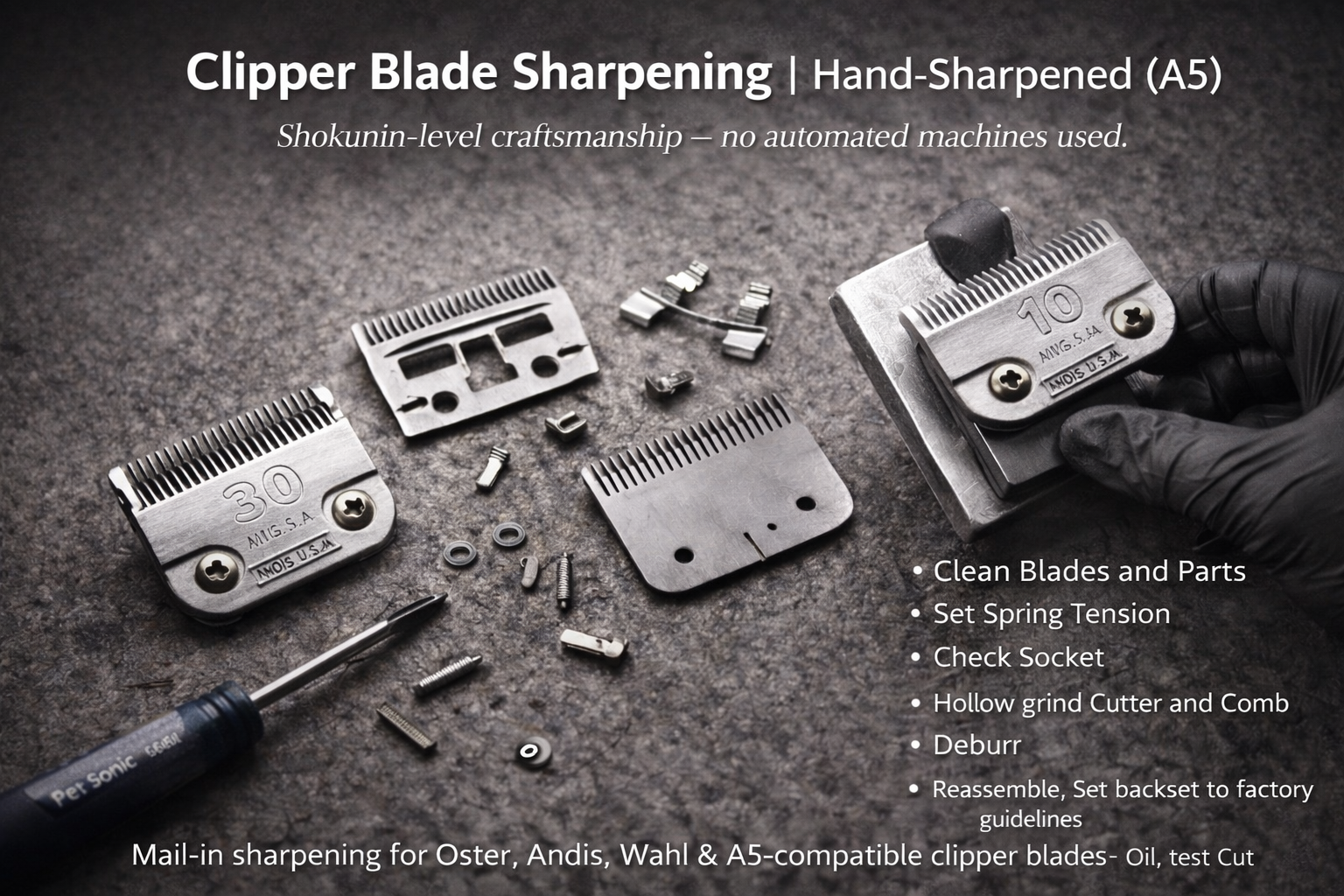

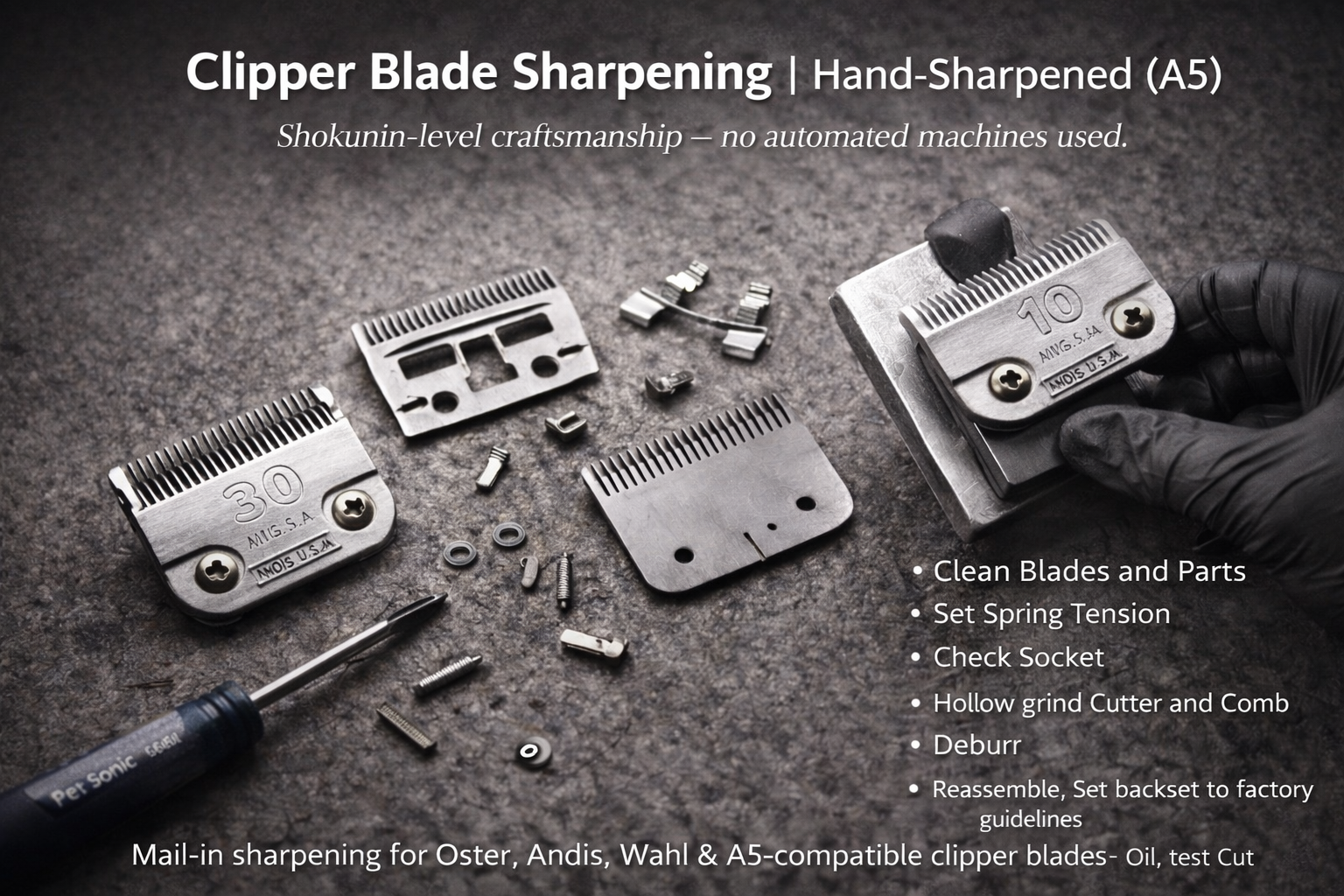

Professional Clipper Blade Sharpening Process

Each blade is serviced using a repeatable, inspection-driven process:

Complete blade disassembly

Ultrasonic and manual cleaning of all components

Spring tension evaluation and adjustment

Socket and wear-surface inspection

Hollow grinding of cutter and comb to restore factory geometry

Precision deburring and edge refinement

Reassembly and factory backset adjustment

Proper lubrication

Final test cutting to verify smooth, consistent performance

This process is designed to deliver reliable cutting performance, extended blade life, and predictable results for professional use.

Quality Control & Turnaround

48-hour shop turnaround after receipt

Ships to all 50 U.S. states

Inspection-verified sharpening

14-day performance guarantee

Who This Service Is For

Professional dog groomers

Barbers using detachable clipper blade systems

Cosmetologists and stylists using A5-style clipper blades

Mobile grooming and barber businesses

Veterinary clinics and animal care facilities

Shops requiring repeatable, accountable clipper blade sharpening

Professional Clipper Blade Sharpening – Hand-Finished Mail-In Service

This professional clipper blade sharpening service is built for dog groomers and veterinary clinics that require consistent cutting performance, correct blade geometry, and repeatable results. It supports professional clipper blade systems used in dog grooming, barbering, cosmetology, and veterinary applications.

Each clipper blade is sharpened individually by hand using documented, process-controlled methods. No automated feed machines, belt sharpeners, or batch grinding systems are used. This approach preserves proper cutter-to-comb interaction, restores factory edge geometry, and prevents premature wear commonly caused by mass-production sharpening.

All sharpening is performed at our Nevada City, California workshop and inspected prior to return.

Clipper Blades Covered by This Service

This service applies to standard professional grooming clipper blades, defined as:

Cutter and/or comb under 2 inches wide

Steel (non-ceramic) components

Professional A5 removable clipper blade systems

Compatible brands include Andis, Oster, Wahl, and equivalent professional clipper systems.

If inspection identifies worn or damaged components, required parts will be replaced as needed to restore proper blade function before return.

Images shown represent examples of clipper blades eligible for this service.

Professional Clipper Blade Sharpening Process

Each blade is serviced using a repeatable, inspection-driven process:

Complete blade disassembly

Ultrasonic and manual cleaning of all components

Spring tension evaluation and adjustment

Socket and wear-surface inspection

Hollow grinding of cutter and comb to restore factory geometry

Precision deburring and edge refinement

Reassembly and factory backset adjustment

Proper lubrication

Final test cutting to verify smooth, consistent performance

This process is designed to deliver reliable cutting performance, extended blade life, and predictable results for professional use.

Quality Control & Turnaround

48-hour shop turnaround after receipt

Ships to all 50 U.S. states

Inspection-verified sharpening

14-day performance guarantee

Who This Service Is For

Professional dog groomers

Barbers using detachable clipper blade systems

Cosmetologists and stylists using A5-style clipper blades

Mobile grooming and barber businesses

Veterinary clinics and animal care facilities

Shops requiring repeatable, accountable clipper blade sharpening