This professional clipper blade sharpening service is built for dog groomers and veterinary clinics that require consistent cutting performance, correct blade geometry, and repeatable results. It supports professional clipper blade systems used in dog grooming, barbering, cosmetology, and veterinary applications.

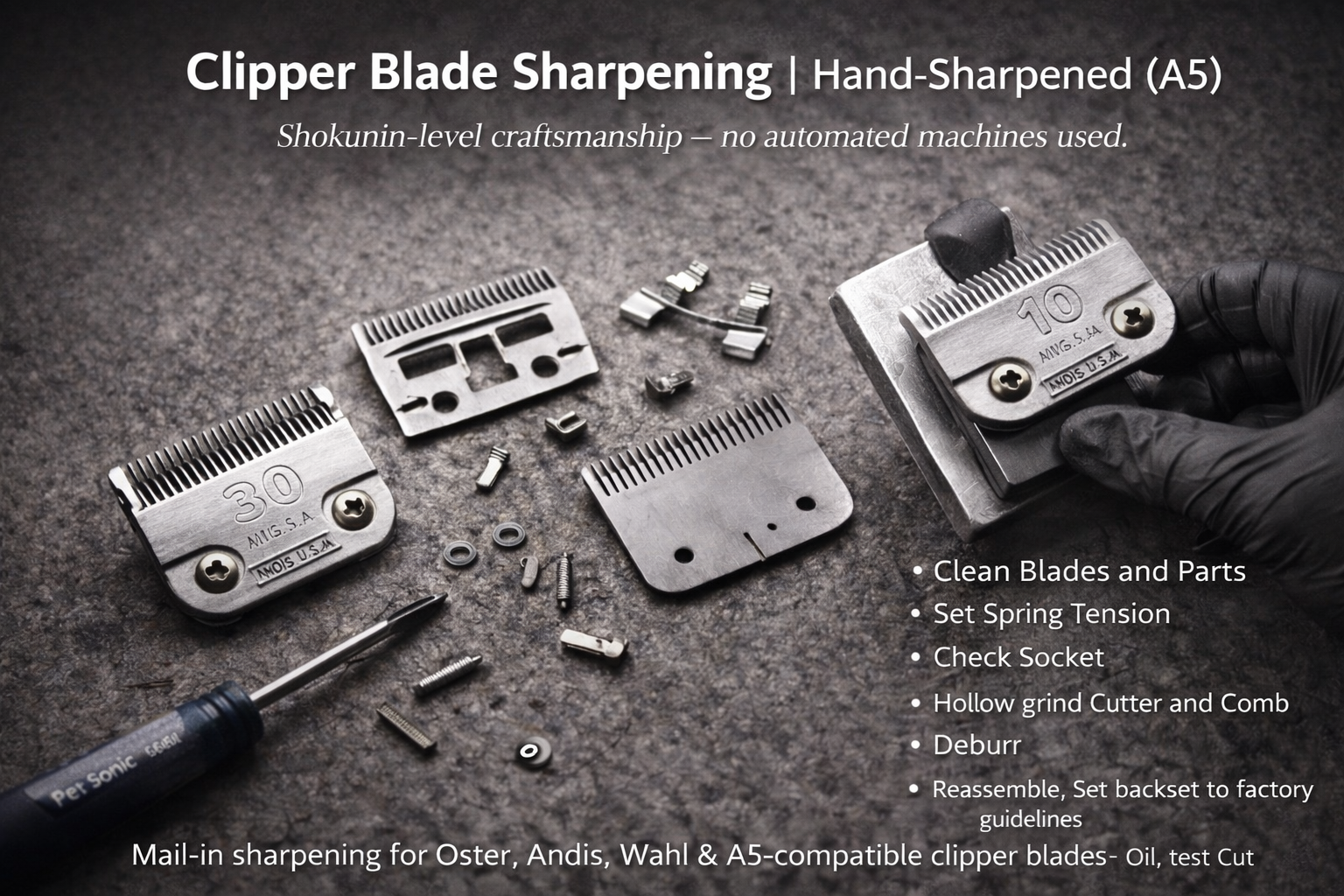

Each clipper blade is sharpened individually by hand using documented, process-controlled methods. No automated feed machines, belt sharpeners, or batch grinding systems are used. This approach preserves proper cutter-to-comb interaction, restores factory edge geometry, and prevents premature wear commonly caused by mass-production sharpening.

All sharpening is performed at our Nevada City, California workshop and inspected prior to return.

This service applies to standard professional grooming clipper blades, defined as:

Cutter and/or comb under 2 inches wide

Steel (non-ceramic) components

Professional A5 removable clipper blade systems

Compatible brands include Andis, Oster, Wahl, and equivalent professional clipper systems.

If inspection identifies worn or damaged components, required parts will be replaced as needed to restore proper blade function before return.

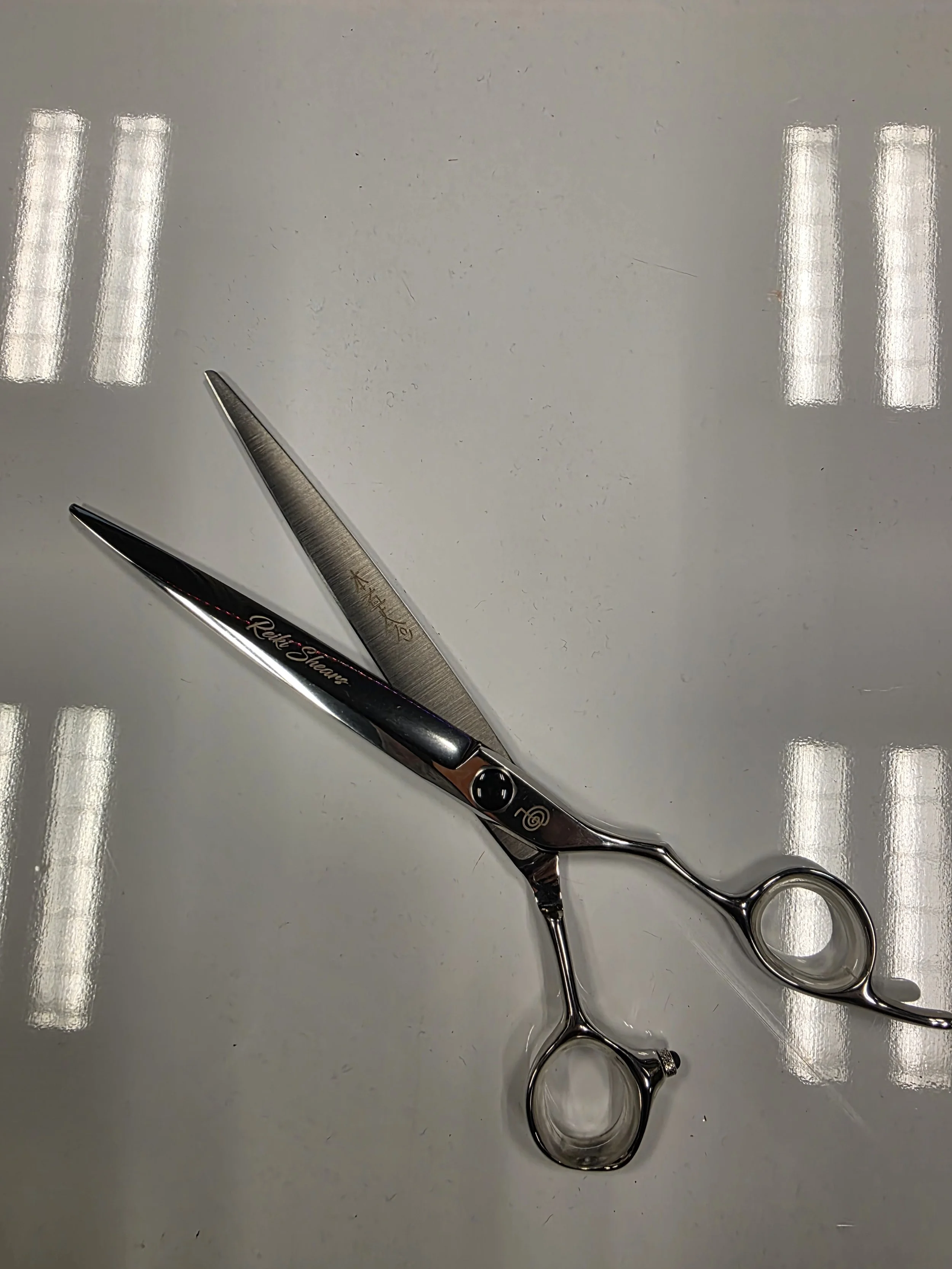

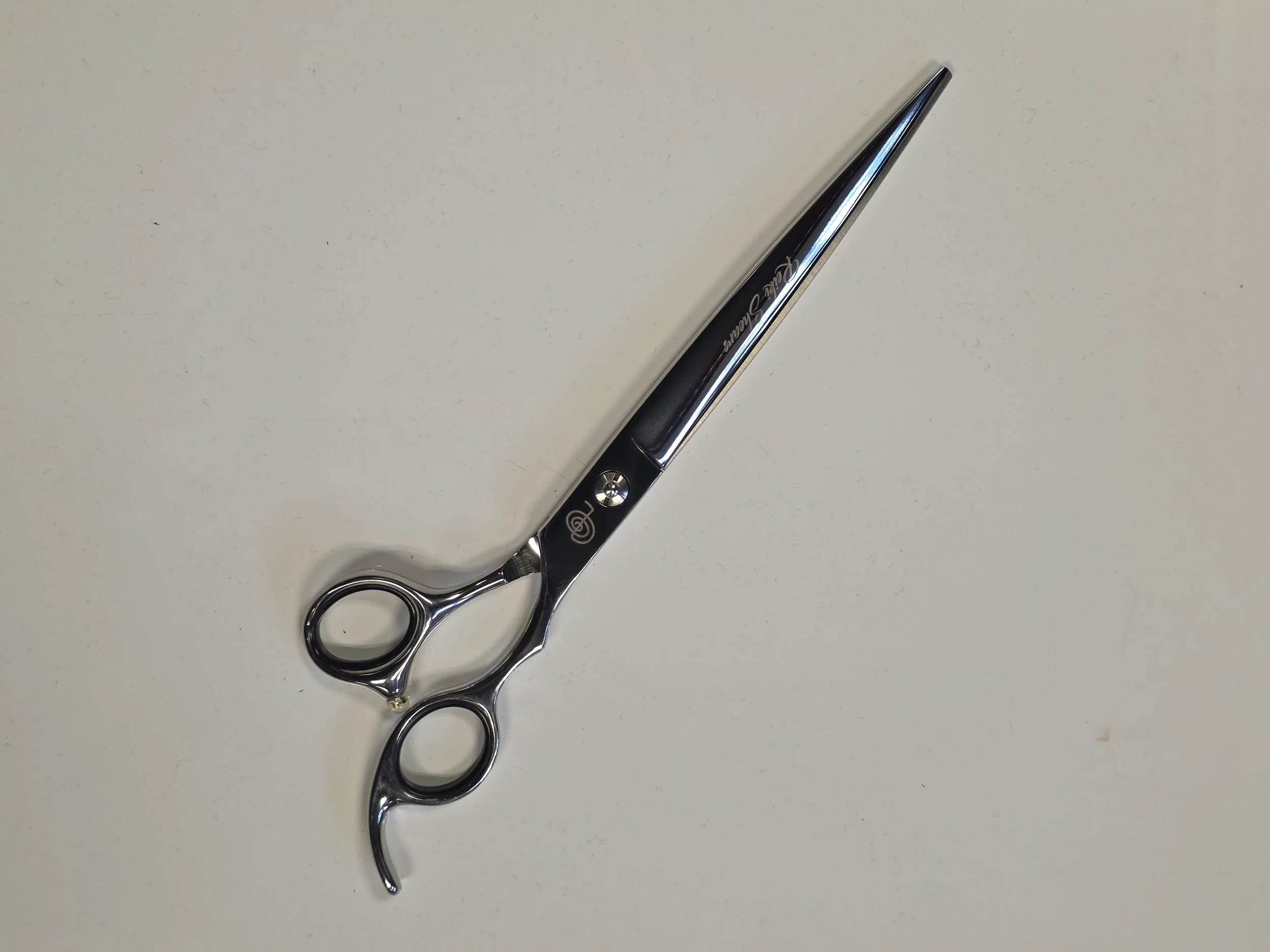

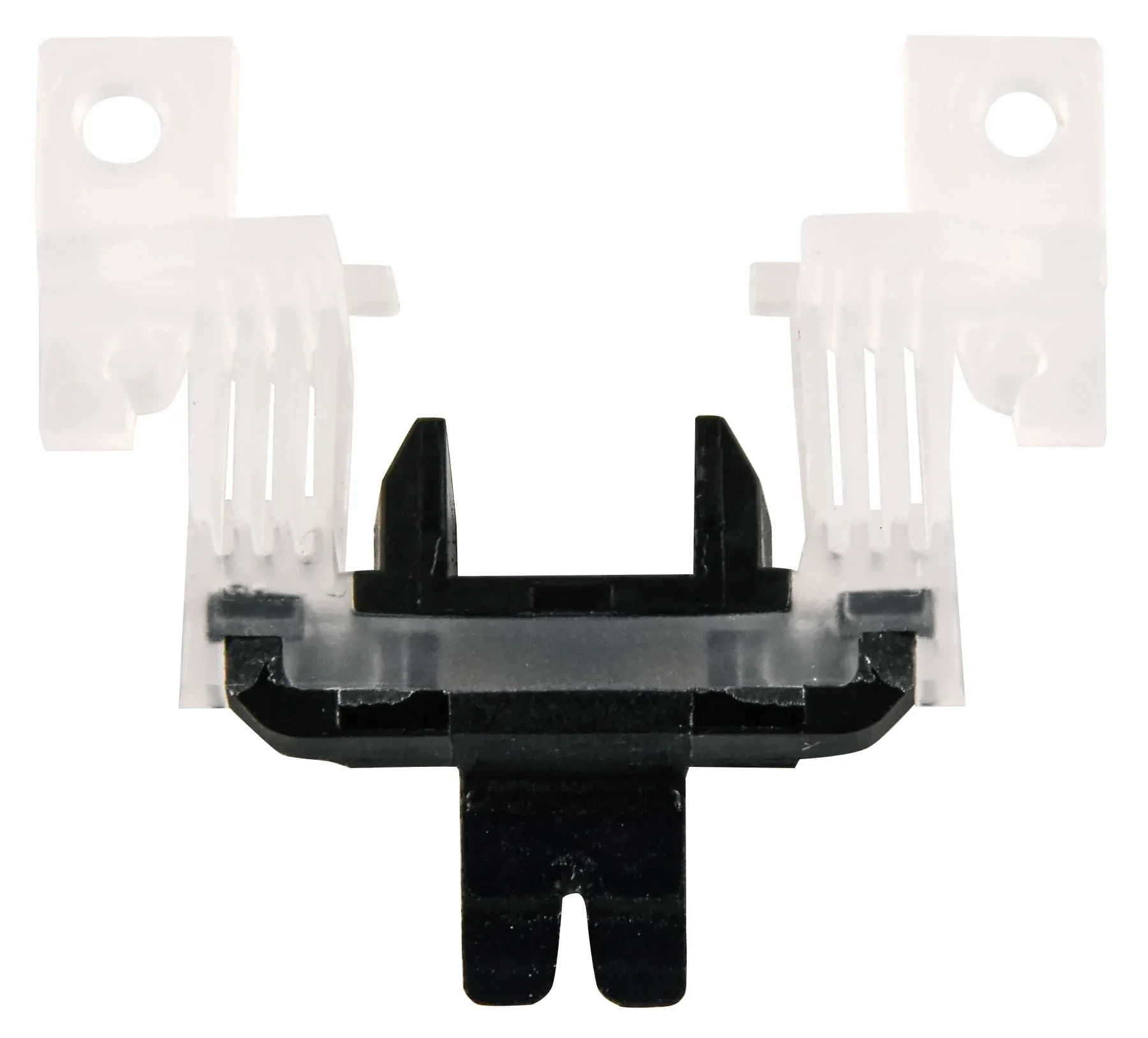

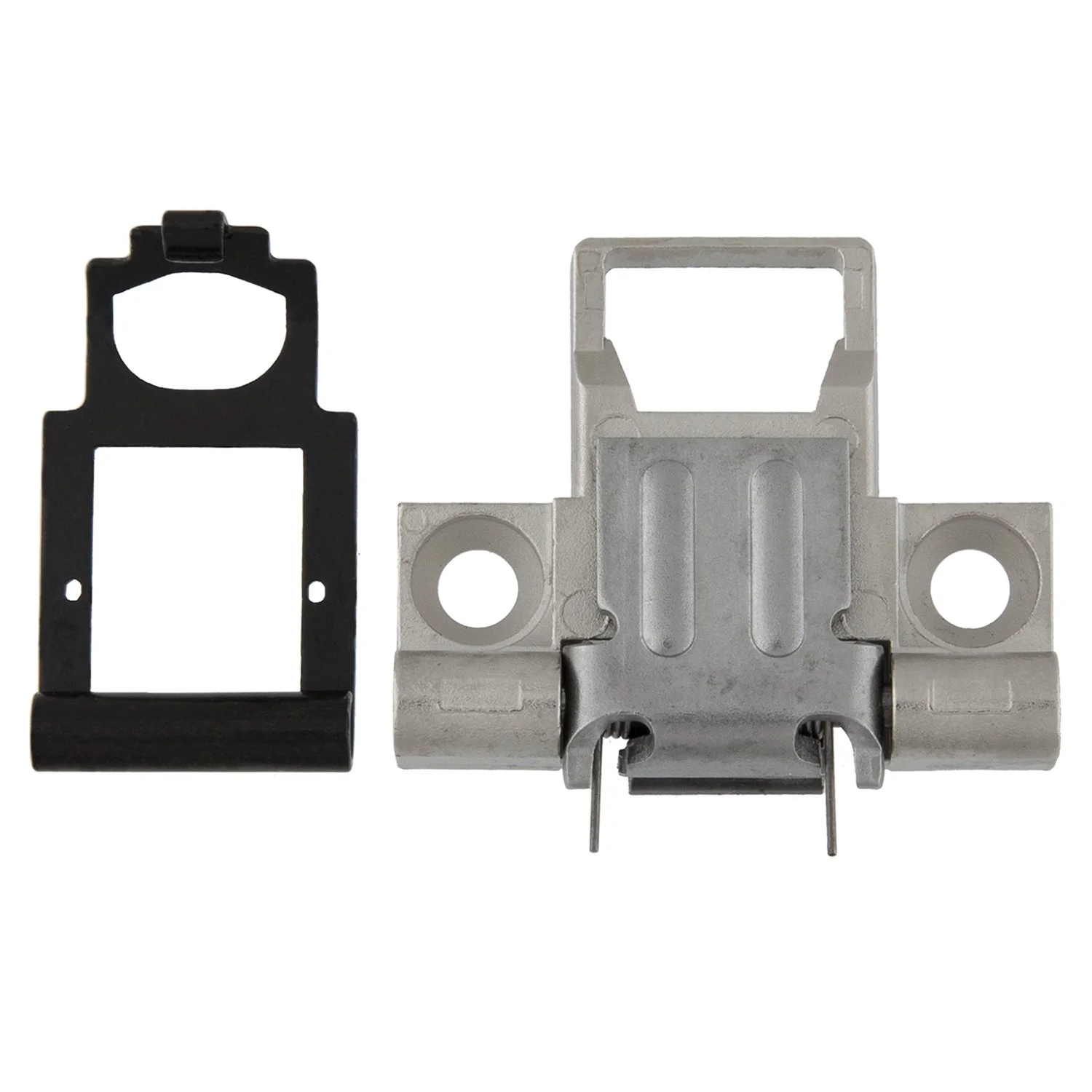

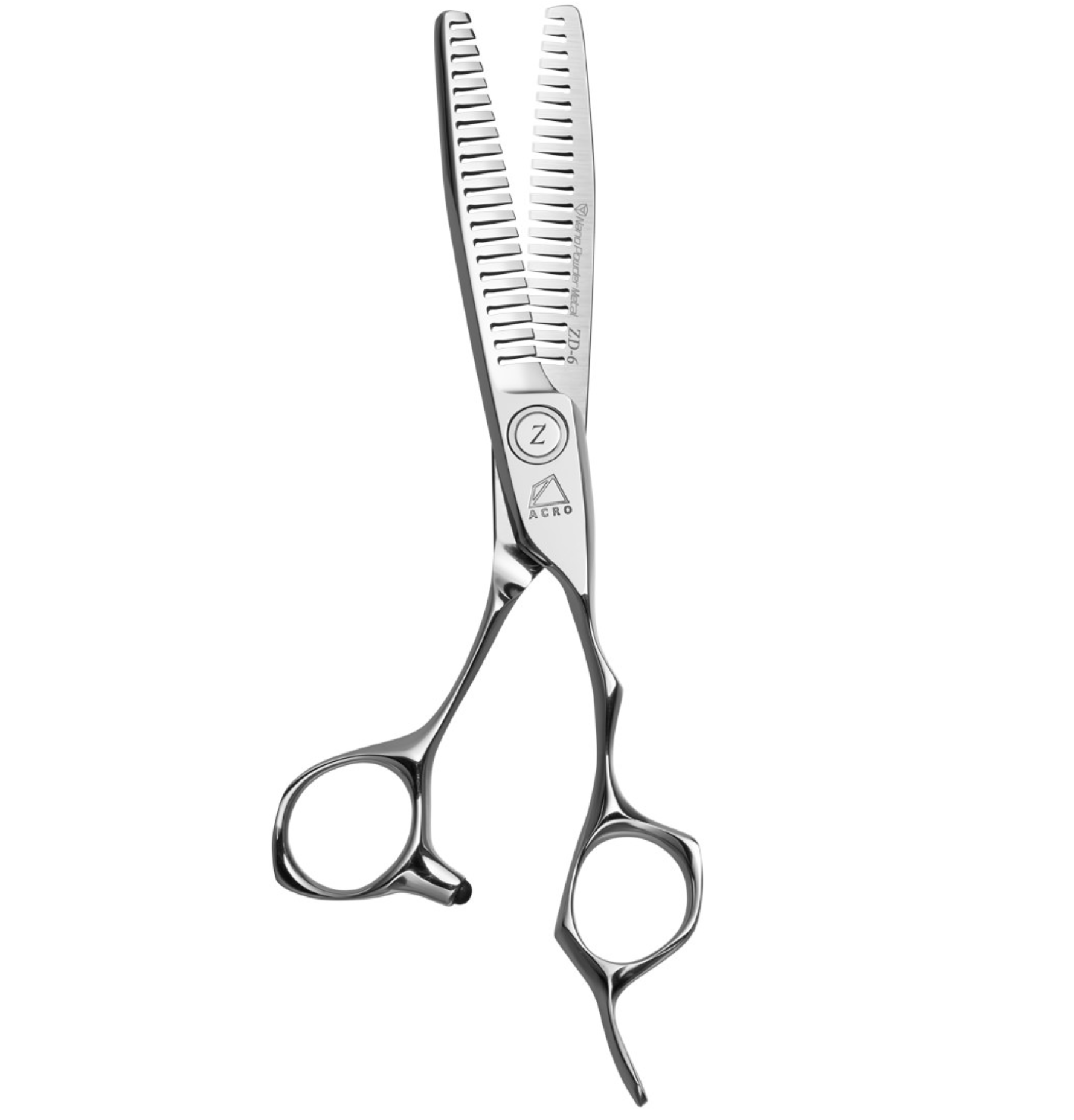

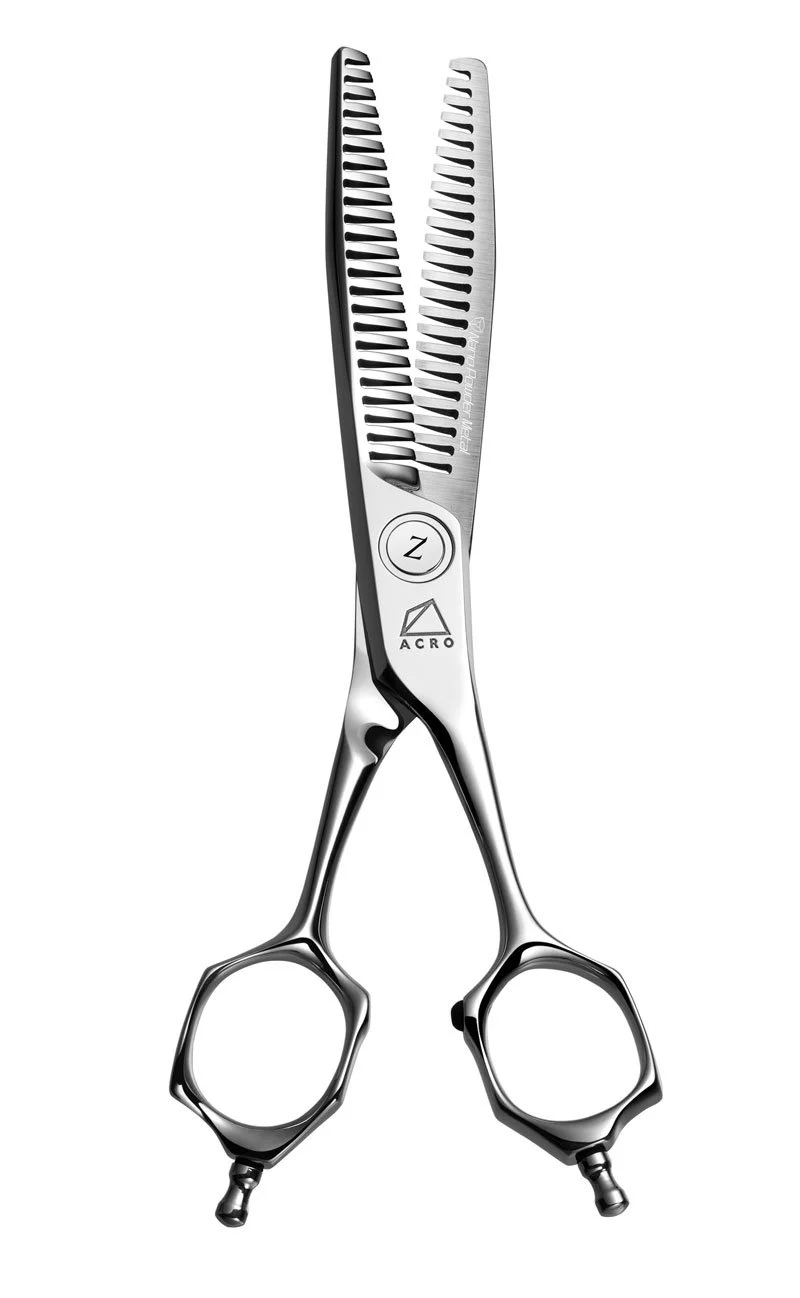

Images shown represent examples of clipper blades eligible for this service.

Each blade is serviced using a repeatable, inspection-driven process:

Complete blade disassembly

Ultrasonic and manual cleaning of all components

Spring tension evaluation and adjustment

Socket and wear-surface inspection

Hollow grinding of cutter and comb to restore factory geometry

Precision deburring and edge refinement

Reassembly and factory backset adjustment

Proper lubrication

Final test cutting to verify smooth, consistent performance

This process is designed to deliver reliable cutting performance, extended blade life, and predictable results for professional use.

48-hour shop turnaround after receipt

Ships to all 50 U.S. states

Inspection-verified sharpening

14-day performance guarantee

Professional dog groomers

Barbers using detachable clipper blade systems

Cosmetologists and stylists using A5-style clipper blades

Mobile grooming and barber businesses

Veterinary clinics and animal care facilities

Shops requiring repeatable, accountable clipper blade sharpening

This wide clipper blade sharpening service is designed for professional groomers and veterinary clinics using wide A5 clipper blades that require precise geometry control across an extended cutting surface.

Wide blades place greater demands on sharpening accuracy due to increased surface area and engagement length. Each blade is sharpened individually with full manual control using documented, inspection-driven methods. No automated feed machines, belt sharpeners, or batch grinding systems are used. This ensures even pressure, correct cutter-to-comb alignment, and consistent cutting performance across the full blade width.

All sharpening is performed at our Nevada City, California workshop and inspected prior to return.

This service applies to wide professional grooming clipper blades, defined as:

Cutter and/or comb over 2 inches wide

Steel (non-ceramic) components

Professional wide A5 removable clipper blade systems

Compatible brands include Andis, Oster, Wahl, and equivalent professional clipper systems.

If inspection identifies worn or damaged components, required parts will be replaced as needed to restore proper blade function before return.

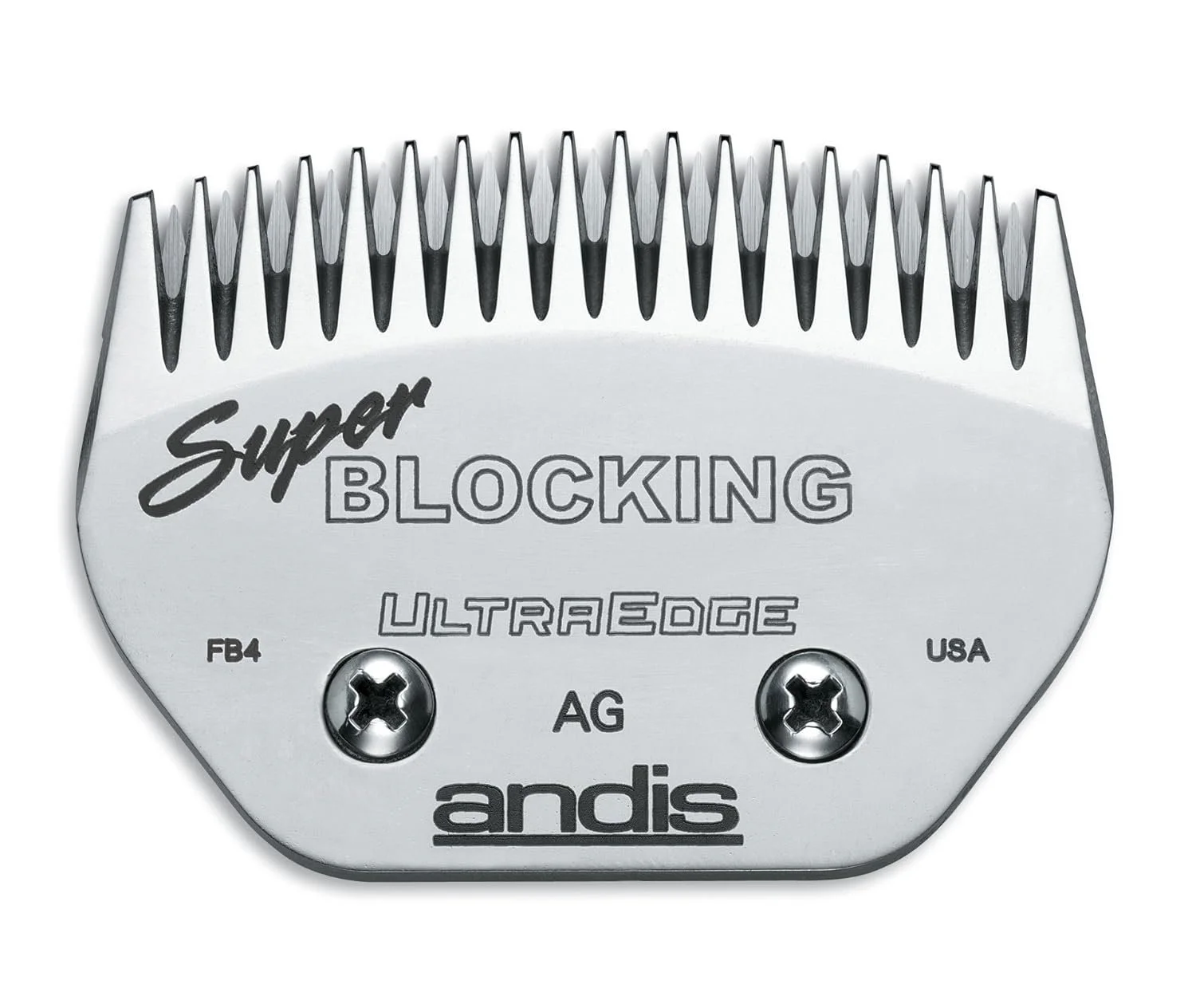

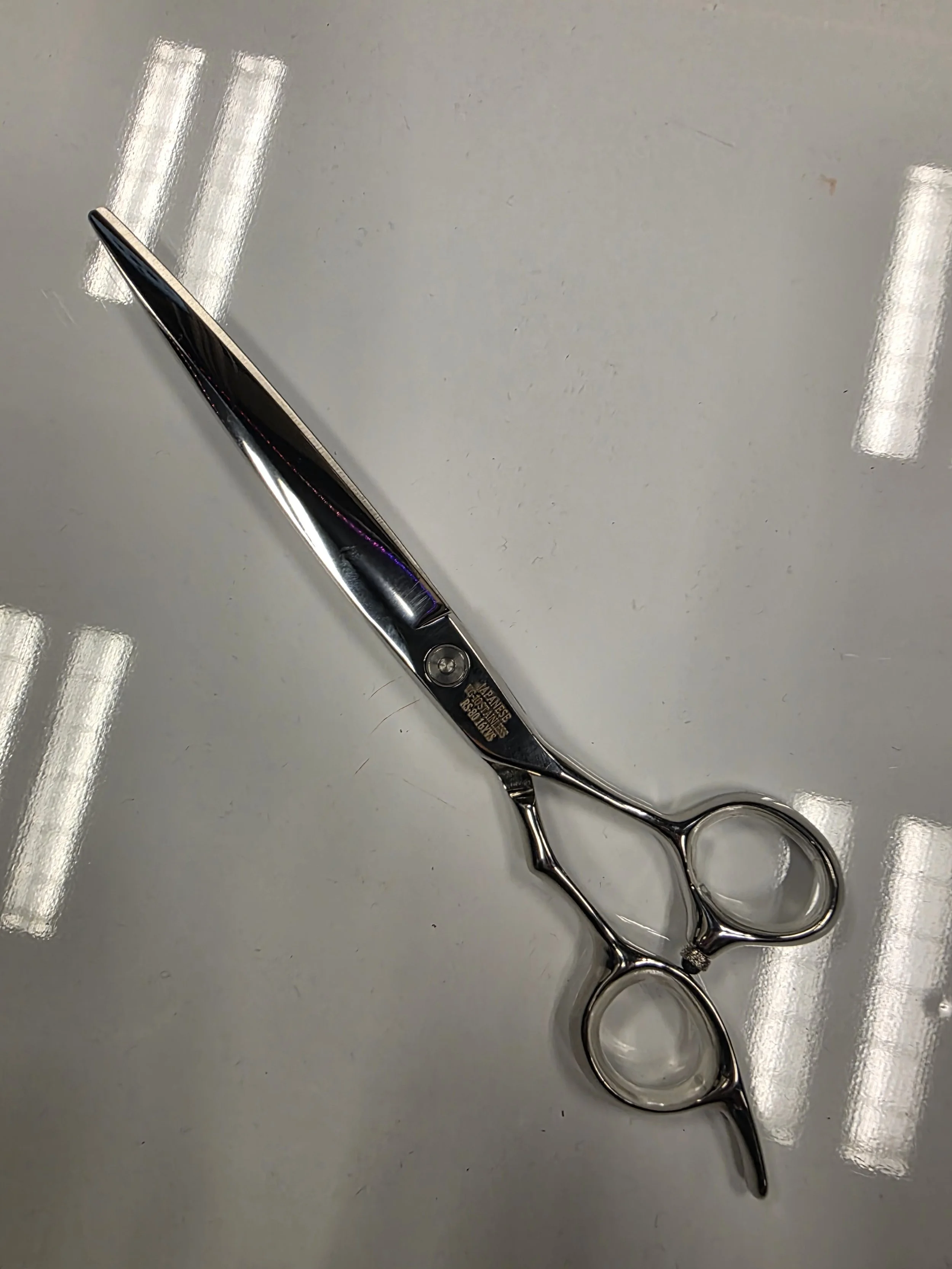

Images shown represent examples of wide clipper blades eligible for this service.

Each wide blade is serviced using a repeatable, inspection-driven process designed to manage increased blade surface area:

Complete blade disassembly

Ultrasonic and manual cleaning of all components

Spring tension evaluation and adjustment

Socket and wear-surface inspection

Precision hollow grinding of cutter and comb to restore factory geometry

Careful deburring to ensure smooth cutter-to-comb engagement

Reassembly and factory backset adjustment

Proper lubrication

Final test cutting to verify smooth, even performance across the full cutting width

This process is designed to deliver uniform cutting performance, extended blade life, and predictable results for wide-format clipper blades.

48-hour shop turnaround after receipt

Ships to all 50 U.S. states

Inspection-verified sharpening

14-day performance guarantee

Professional dog groomers using wide blades

Mobile grooming businesses

Veterinary clinics

High-volume grooming salons

Shops requiring repeatable, accountable sharpening for wide clipper blades

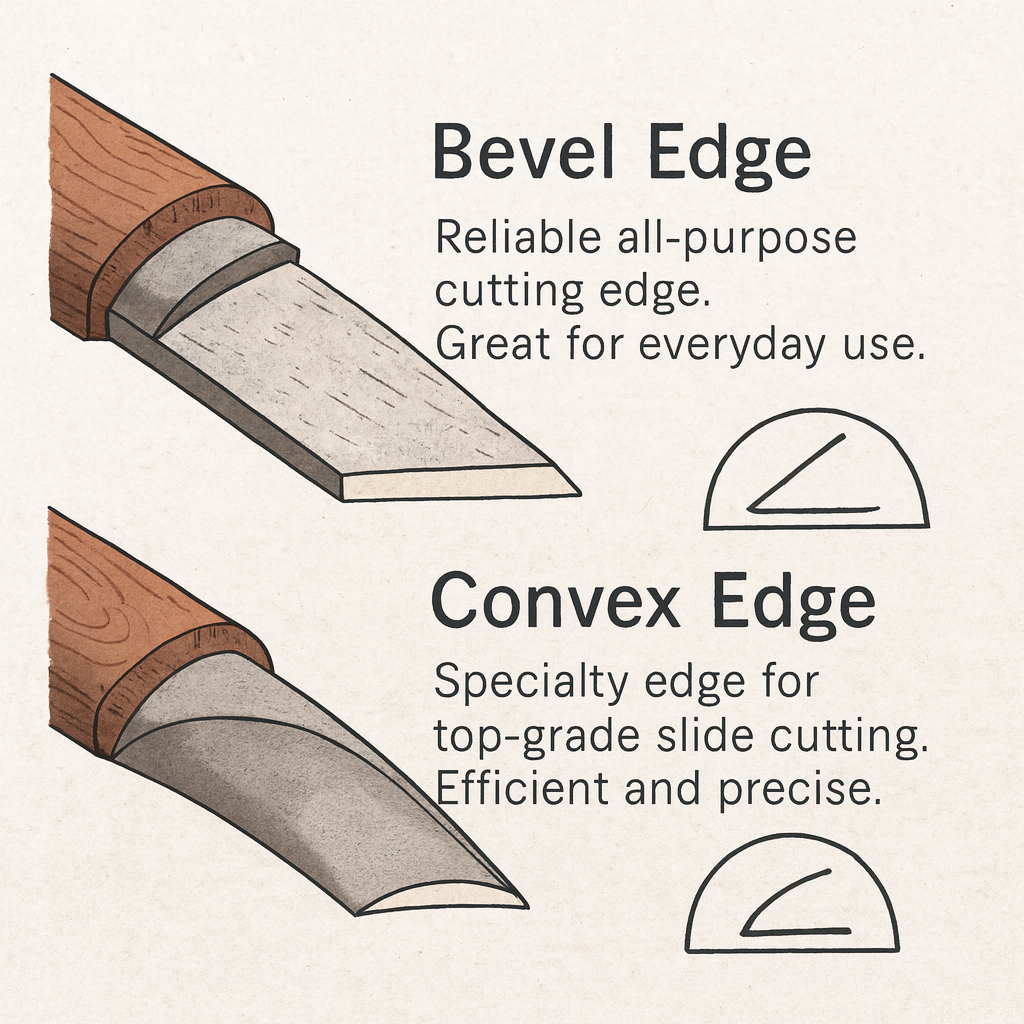

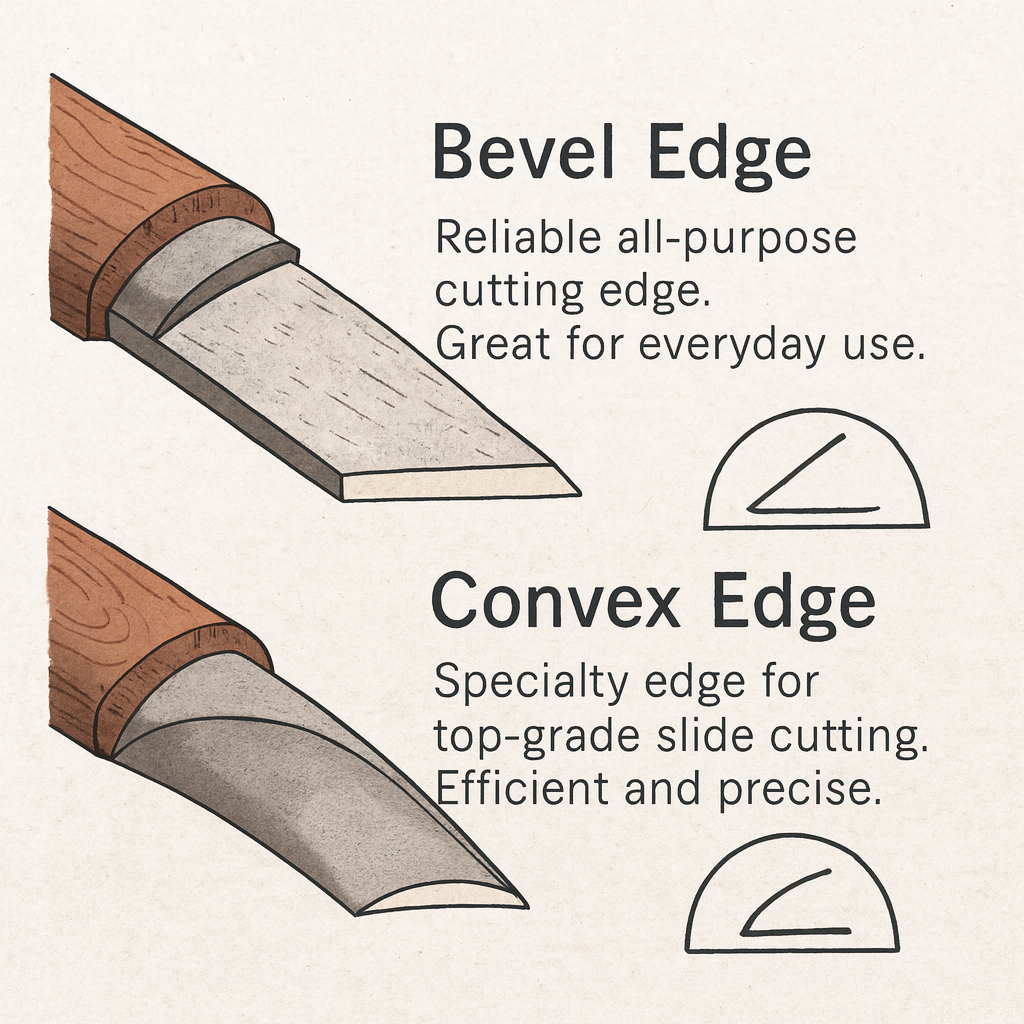

This Professional Beveled Shear Sharpening service is designed for everyday working dog grooming shears with a beveled (German-style) edge. It applies to straight or curved grooming shears of any length, including thinners and chunker/texturizer shears used in high-volume grooming environments.

Basic Beveled Sharpening is ideal for reliable, professional grooming tools that require consistent cutting performance, proper mechanical setup, and dependable results, without the extended time or edge refinement required for convex or premium shear services.

All work is performed using repeatable, inspection-driven methods focused on function, longevity, and safe daily use.

This service applies to:

Beveled (German-style) grooming shears

Straight or curved grooming shears

Thinning shears

Chunker / texturizer shears

Designed specifically for dog grooming tools, not barber or cosmetology shears.

Each shear is serviced using a proven, repeatable process focused on function and consistency:

Complete shear disassembly

Thorough cleaning of all components

Detailed inspection of edge, pivot, and hardware

Replacement of worn washers or hardware as needed

Topside sharpening on a flat hone to restore the original factory bevel edge (unless otherwise specified)

Re-establishment of the factory ridgeline (inside face), when applicable

Reassembly

Proper tension setting

Final test cutting with no lateral pressure (no thumb or finger bias)

This process delivers clean cutting action, mechanical reliability, and consistent performance for daily grooming work.

48-hour shop turnaround after receipt

Ships to all 50 U.S. states

Inspection-verified sharpening

14-day performance guarantee

Professional dog groomers

Mobile grooming businesses

High-volume grooming salons

Groomers needing reliable daily-use sharpening without premium pricing

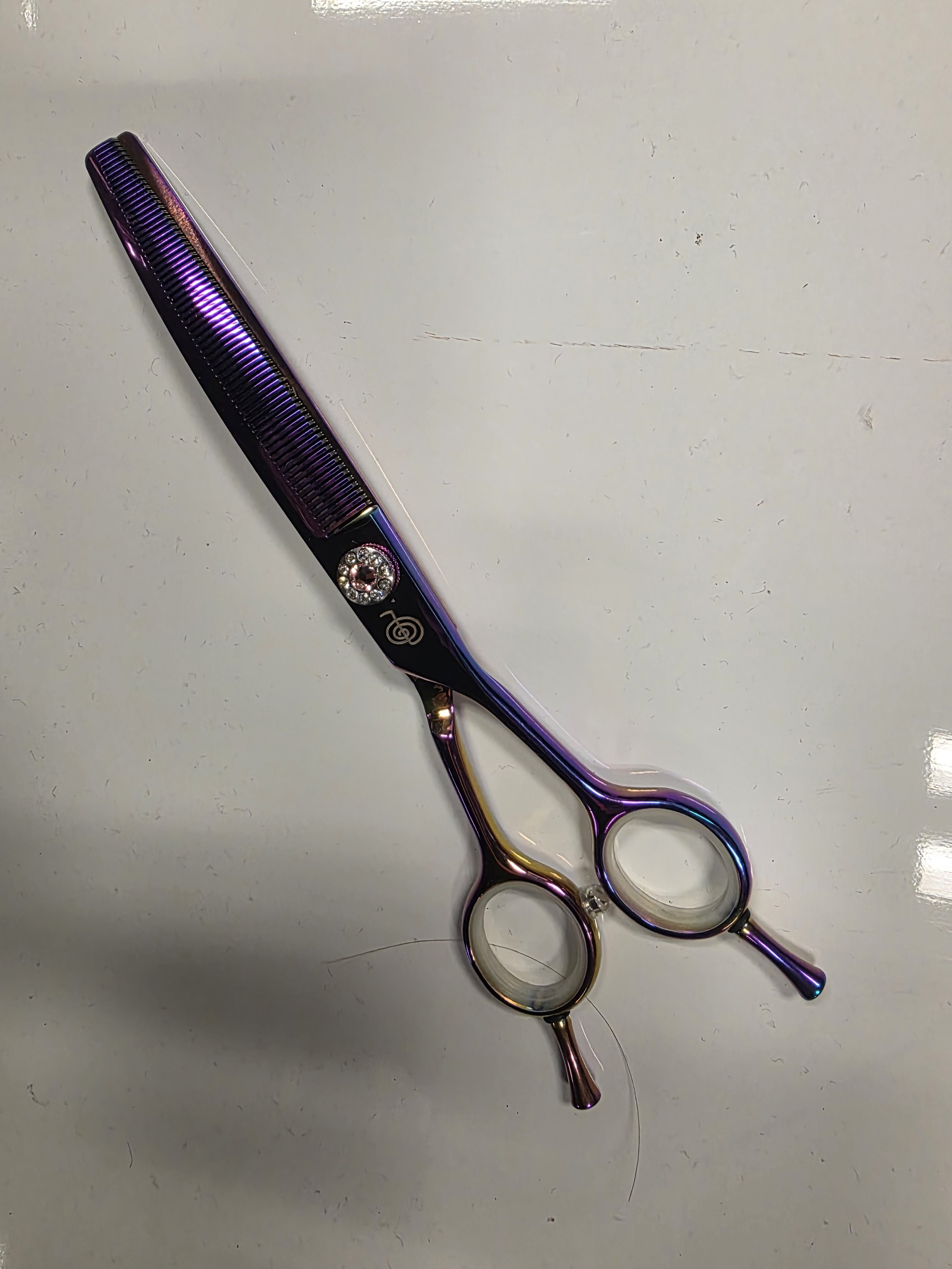

The Conduit Series Anodized Curved Blender is designed for seamless blending, soft transitions, and refined finishing—where smoothness matters more than force.

Crafted from VG-10 Japanese stainless steel, this curved blender features precision-cut blending teeth and a full convex working edge, delivering exceptionally fluid motion with no grabbing, chatter, or harsh lines. The curvature follows natural form, allowing effortless control while reducing hand and wrist fatigue during detailed work.

Finished in a purple-pink anodized coating, this shear is both visually striking and functionally durable—resistant to corrosion while maintaining a balanced, lightweight feel. A precision nylon glide system ensures consistently smooth action and controlled tension, even during extended sessions.

Intentional sigil markings act as visual anchors for presence and care, reflecting the philosophy behind the tool rather than claiming effect. Designed by a Holy Fire Reiki Master and professional sharpener, this blender is meant to support calm focus, confidence, and clean results—whether working with people or animals.

Fully serviceable and supported by our in-house premium craft sharpening, this shear is built for artists who demand smoothness, precision, and longevity.

This service is for large animal clipper blades used on horses, cattle, livestock, and other heavy-coat animals. These blades are manufactured from thicker steel and designed to operate under higher torque loads than standard grooming or salon clipper blades.

Large animal blades require a different sharpening approach than small grooming blades. Proper service focuses on restoring cutting efficiency while maintaining edge durability and heat resistance suitable for extended use and dense coats.

Each blade is inspected prior to sharpening to confirm it is mechanically sound and within safe service limits. Blades that cannot be safely serviced will be identified before work proceeds.

Pre-service inspection

Professional sharpening appropriate for heavy-duty blade geometry

Cleaning and functional testing

Return shipping included with mail-in orders

Not all large animal clipper blades are serviceable.

The following may be declined or returned unserviced:

Blades with excessive thinning or deep structural damage

Blades with broken teeth or severe corrosion

Blades previously overheated or improperly ground

Blades outside safe cutting tolerances

If a blade is not suitable for sharpening, you will be contacted before any work is performed.

Turnaround time is defined by the Mail-In Sharpening system and depends on condition and order volume. Shipping transit time is not included.

Secure blades to prevent movement during shipping

Remove loose hair, debris, or excessive buildup if possible

Include your contact information in the package

Add this service to your Mail-In Sharpening order

Ship using your preferred carrier

Equine professionals

Livestock handlers

Mobile large-animal grooming services

Agricultural and ranch operations

Equine · Livestock · Heavy-Duty Clipper Blades

Oster-Andis-Wahl

Standard grooming clipper blades

5-in-1 adjustable blades

Cosmetic restoration or display blades

Those are a different Line Item

This service prioritizes durability, safety, and consistent cutting performance for demanding large-animal environments.

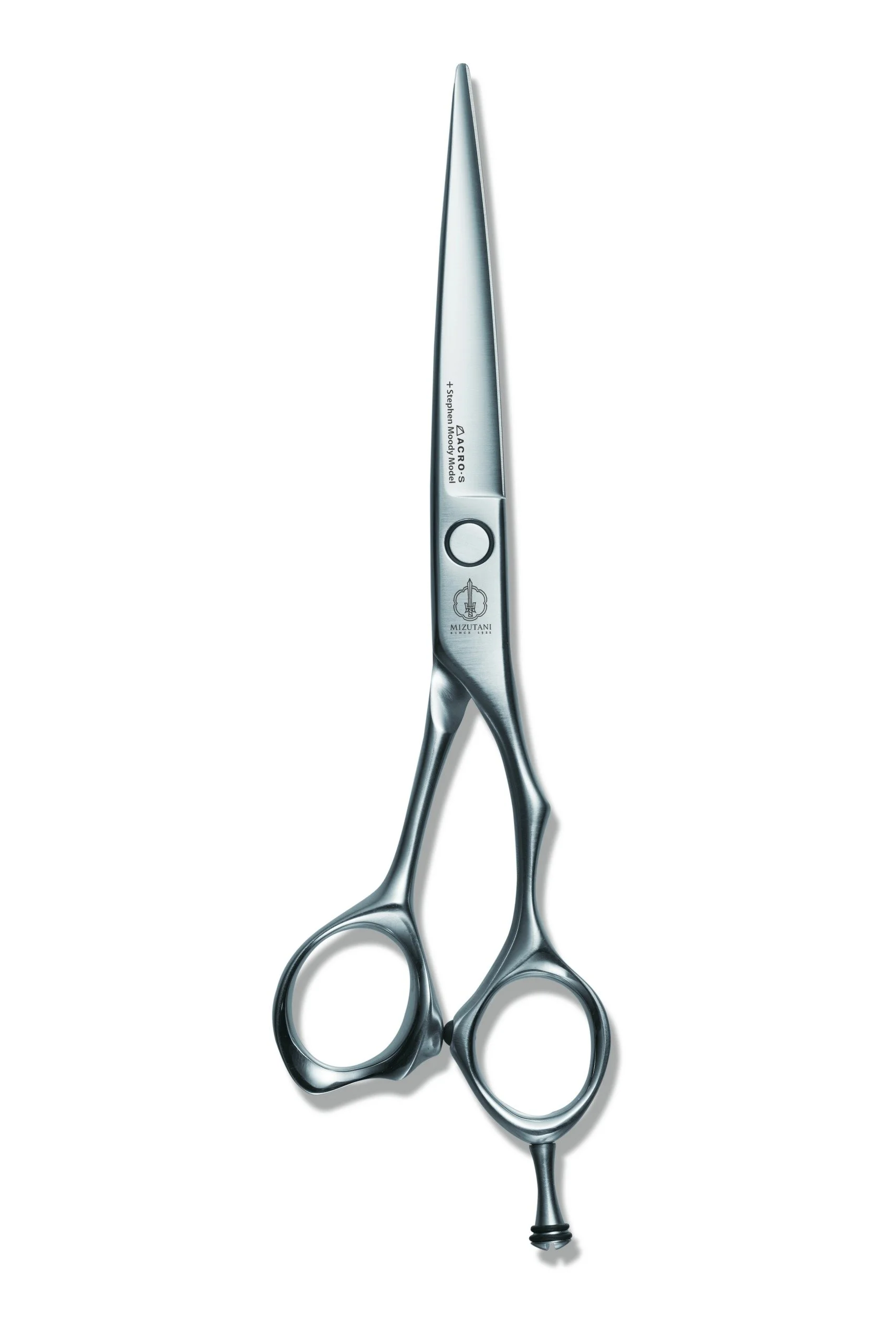

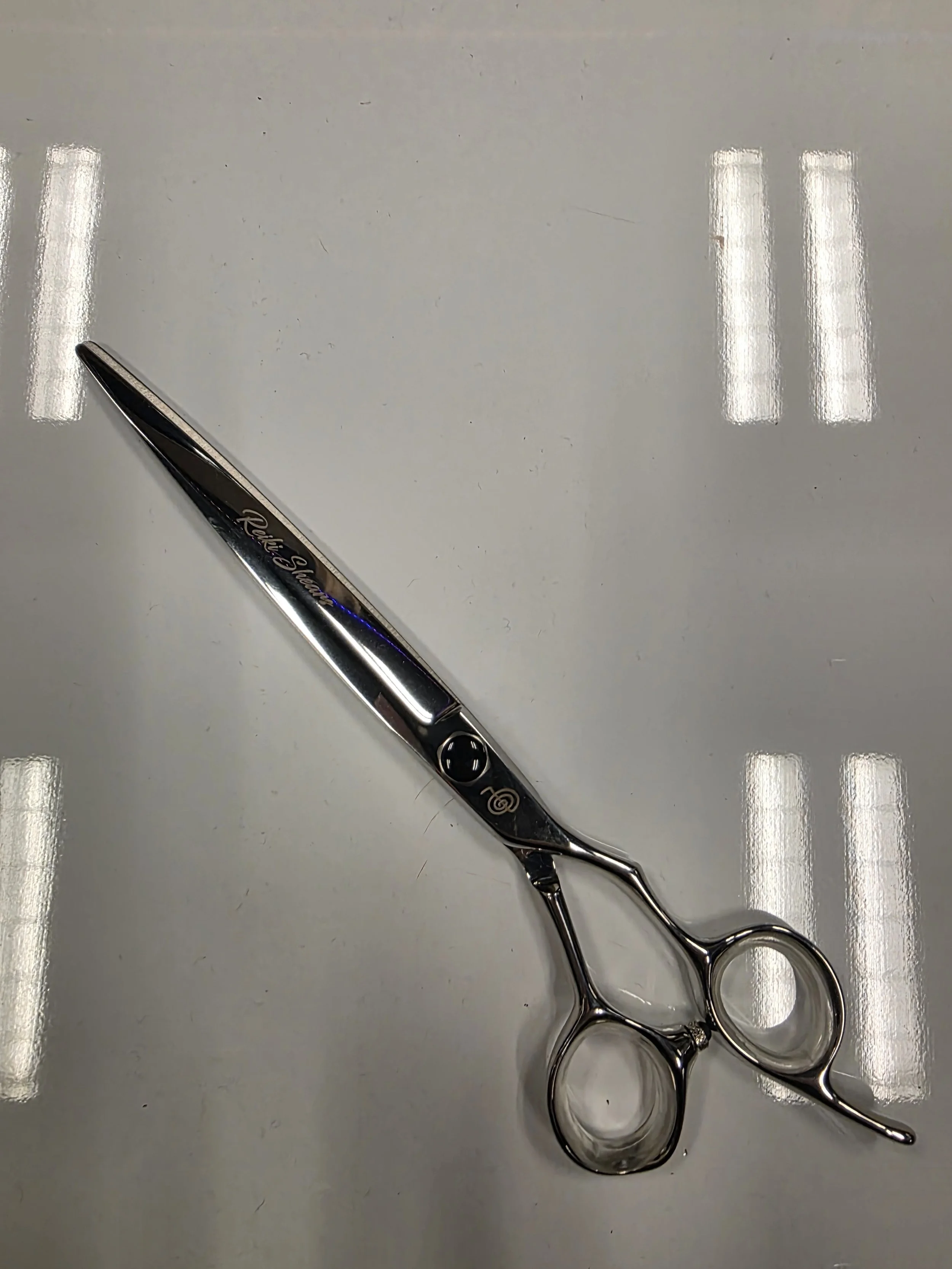

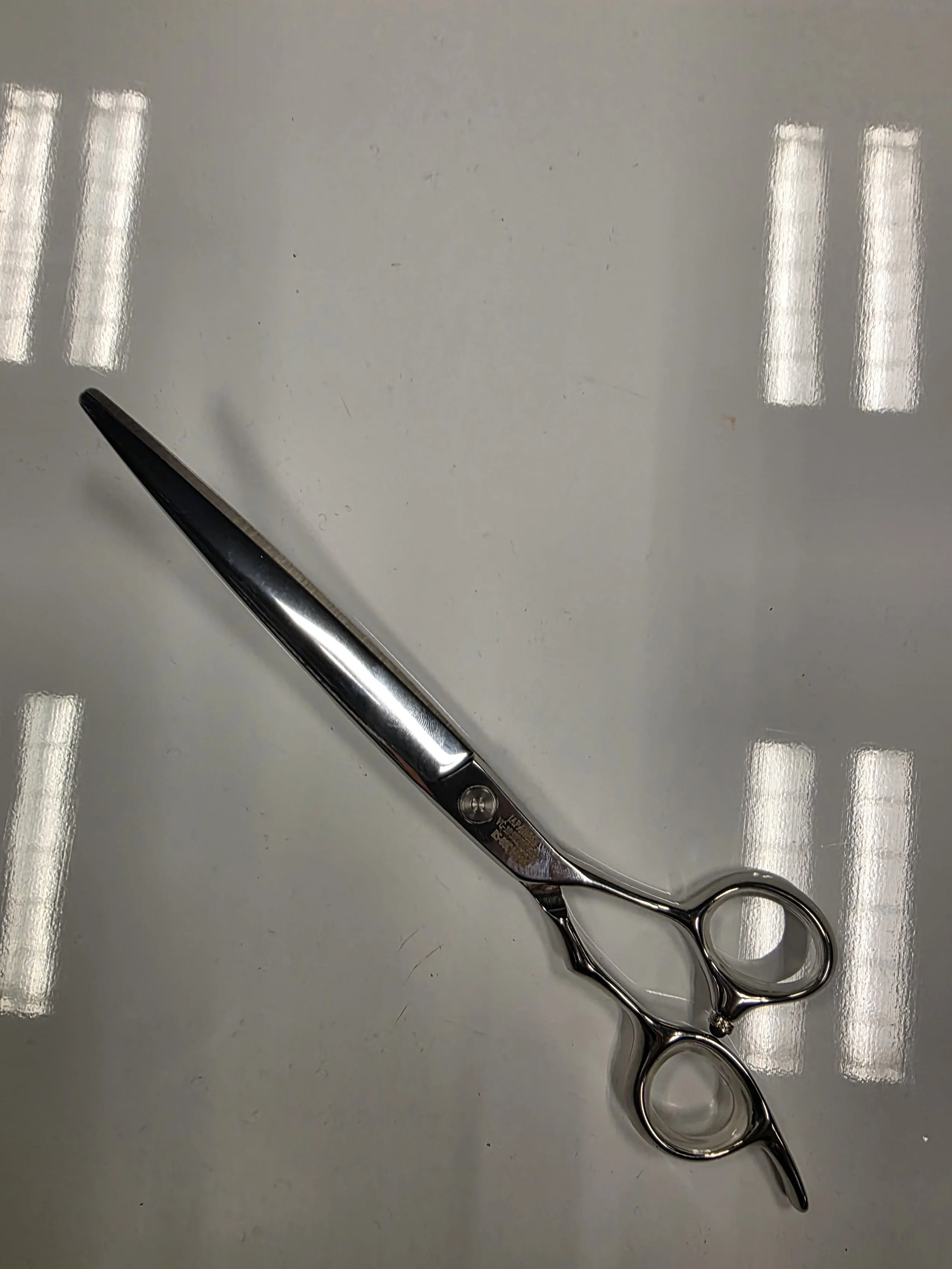

This Premium Convex Barber & Beauty Shear Sharpening service is designed for high-precision barber and cosmetology shears manufactured with true convex (Japanese-style) edge geometry. It applies to straight or curved convex shears of any length, typically valued in the $400+ range and produced with brand-specific factory tolerances.

Unlike standard or volume sharpening, premium barber and beauty shears require exact identification of original factory geometry, cutting intent, and dynamic edge behavior. This service uses inspection-driven, process-controlled methods to restore cutting performance without altering or generalizing the original design.

If you own a select set of high-end barber or cosmetology shears and do not want them serviced the same way as everyday working tools, this is the correct sharpening tier.

Typical turnaround: 1–3 weeks

This service is intended for professional convex barber and cosmetology shears, including:

Straight convex barber shears

Curved convex barber shears

High-end cosmetology cutting shears

Premium thinning and texturizing shears

This service is not intended for dog grooming shears.

Sharpening is performed by a Mizutani-certified sharpener, ensuring factory-aware handling of high-end Japanese convex shears and equivalent premium tools.

Common brands serviced include (not limited to):

Mizutani

Utsumi

Above

Green Mouse (PIO)

Dream

Top-tier Kenchii models

Other premium Japanese, Korean, and high-end Chinese barber and cosmetology shear manufacturers

Brand listings are representative.

Each shear is evaluated individually — factory geometry is identified, not assumed.

Each shear is serviced using a disciplined, factory-conscious process designed for precision and risk control:

Complete shear disassembly

Thorough cleaning of all components

Detailed inspection of edge geometry, pivot condition, and hardware

Replacement of worn washers or hardware as required

Precision convex sharpening to restore original factory angles (unless otherwise specified)

Re-establishment of the factory ridgeline (inside face), when applicable

Reassembly

Precision tension setting

Final test cutting with no lateral pressure (no thumb or finger bias)

This process prioritizes cut accuracy, edge longevity, and mechanical integrity over speed.

1–3 week turnaround depending on shear condition and workload

Inspection-verified sharpening

Mechanical setup verified before return

14-day performance guarantee

Professional barbers using premium convex shears

Cosmetologists working with high-end, brand-specific tools

Professionals who require factory-accurate results, not generalized sharpening

A blunt cutting tool optimal for barbering techniques. It has a sturdy weight, with a semi offset handle featuring a large thumb ring. ( Inserts available upon request ). 100% hand made, every marking you see on this model is created by a hammer in hand resulting in the distinctive texture of this shear.

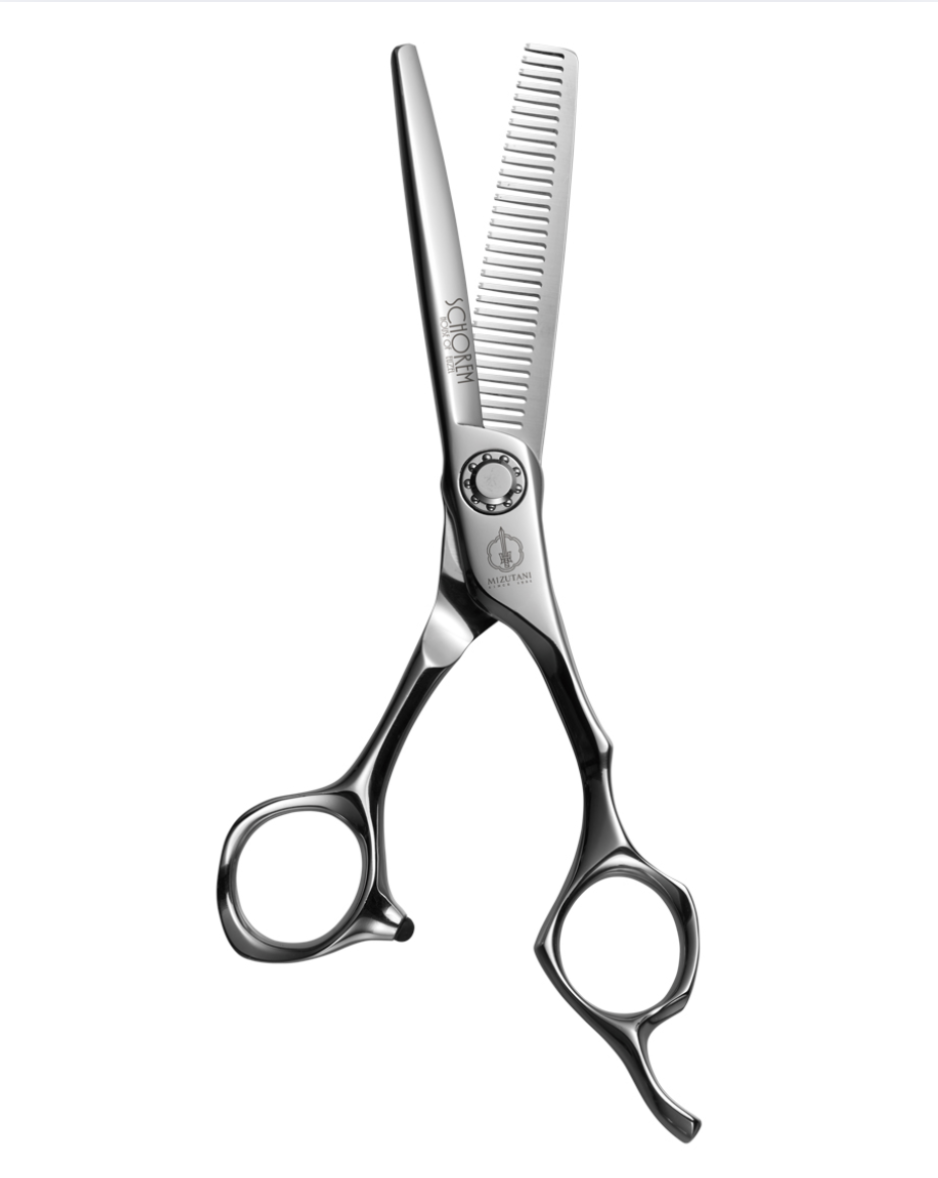

Out of all of the creativity and business success realized within the beauty industry, Schorem Haarsnijder En Barbier based out of Rotterdam, Netherlands has left one of the most pronounced marks within the barber culture.

At Mizutani, we work to service the best by the support of the best. The early days of learning fundamentals as an artist, learning the architecture of how to create hairstyles in combination with knowledge of your instrument for production becomes an integral part of the joy experienced behind the chair as a hairdresser matures in their career.

One such tool is this collaboration model with Leen from Schorem.

“This scissor is influenced by Brutalism”.

A type of design characterized by the use of concrete, as well as industrial materials such as wood, glass, steel, brass, and brick. In terms of shapes and forms, brutalist design is organic, with rough and unpolished textures.

** The Schorem series within the Mizutani collection has become widely known as our signature barbering tool.

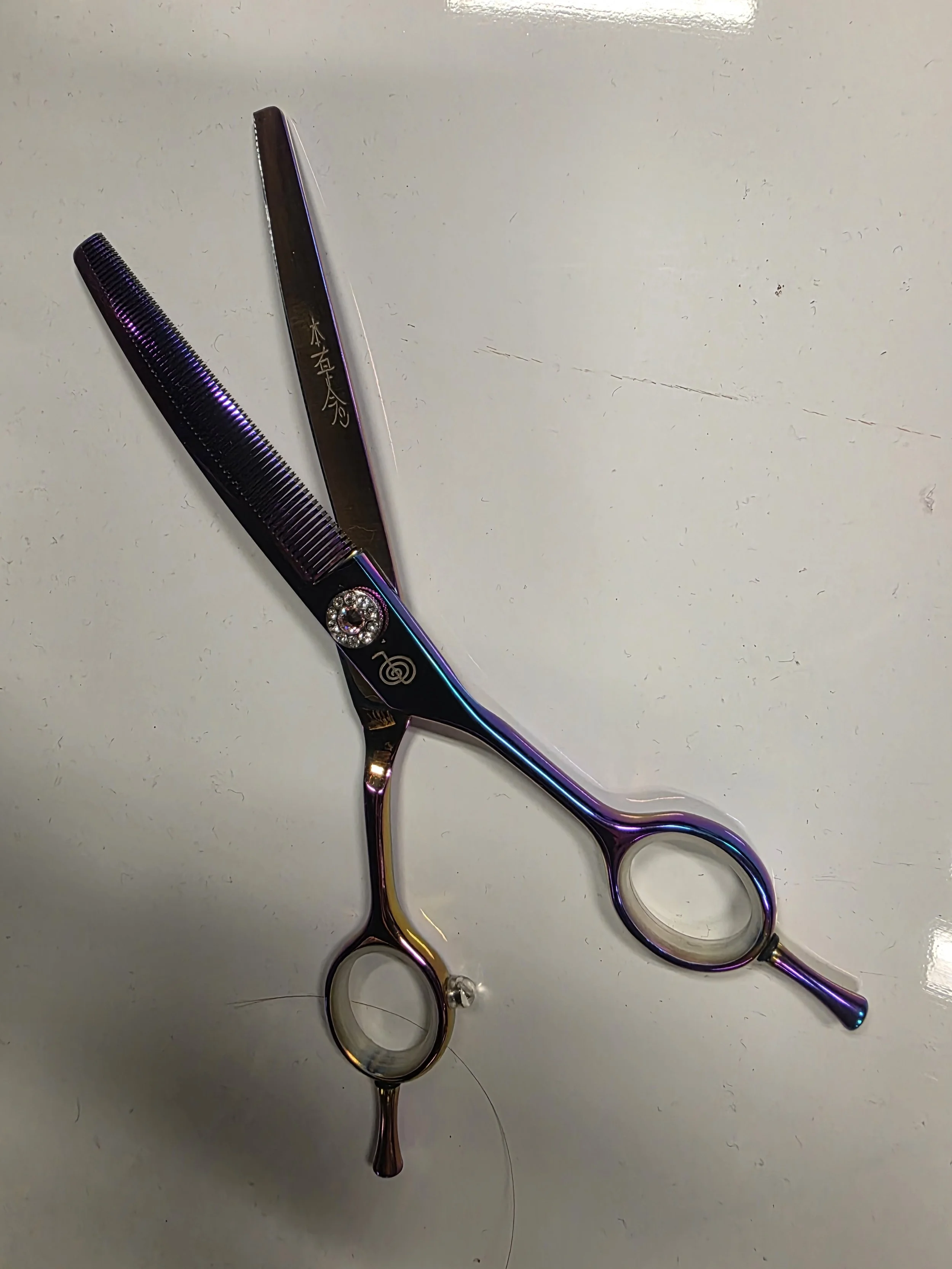

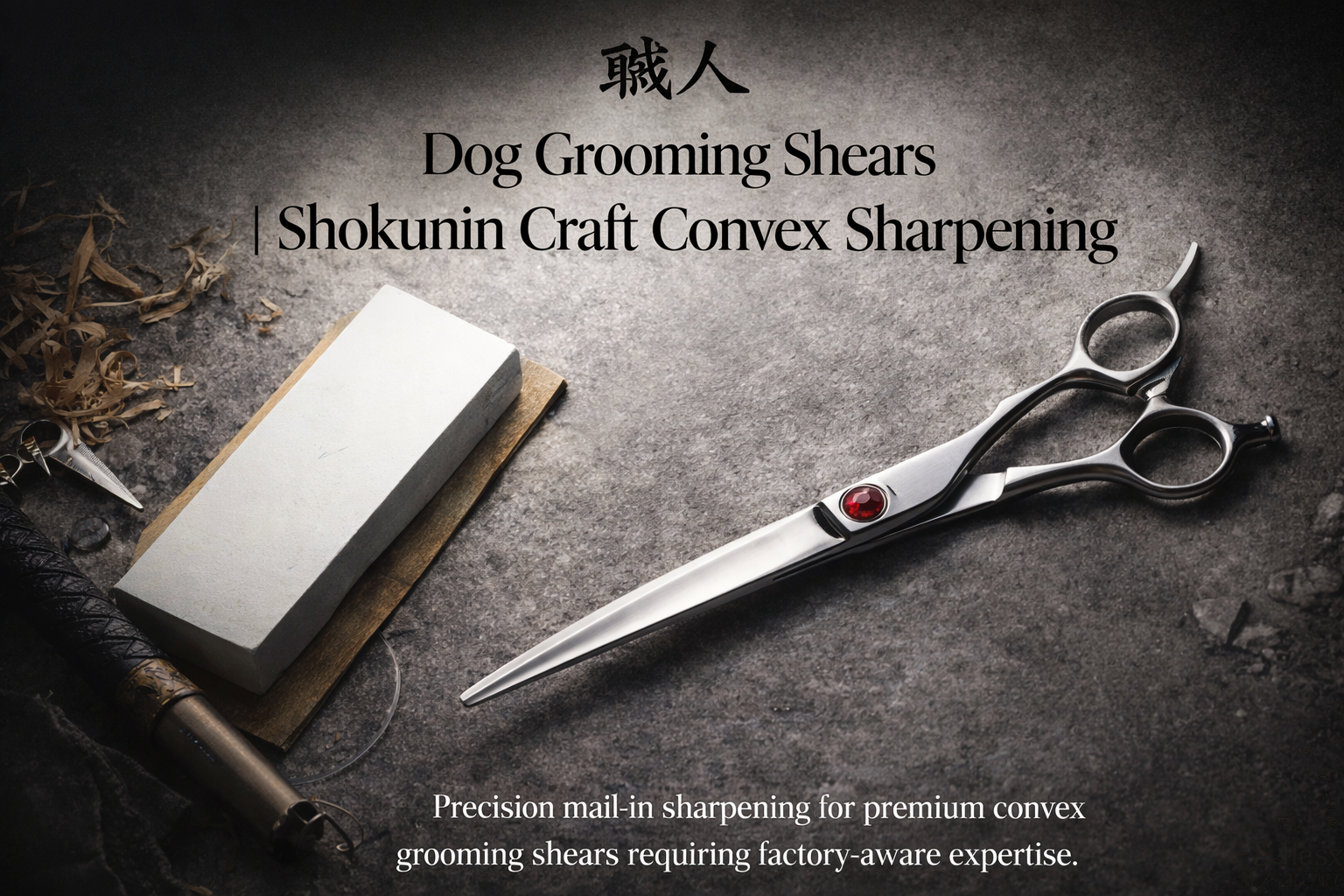

This Premium Convex Grooming Shear Sharpening service is designed for high-end, name-brand convex grooming shears used by professional dog groomers who require maximum cutting performance, precise edge geometry, and strict mechanical accuracy.

This service applies to straight or curved convex grooming shears of any length, including premium thinning and texturizing shears, typically valued in the $300+ range and manufactured with factory-specific convex edge profiles.

Unlike basic beveled sharpening, premium convex shears require a sharpener capable of accurately identifying original factory geometry, intended cutting application, and dynamic shear behavior. This service uses inspection-driven, process-controlled methods to restore performance without altering the shear’s designed cutting characteristics.

If you own a small number of high-value grooming shears and do not want them sharpened like everyday working tools, this is the correct service level.

Typical turnaround: 1–3 weeks

This service is intended for professional convex grooming shears, including:

Straight convex grooming shears

Curved convex grooming shears

Premium thinning shears

High-end chunker / texturizer grooming shears

Designed specifically for dog grooming shears, not barber or cosmetology shears.

Utsumi

Above

Green Mouse (PIO)

Dream

Top-tier Kenchii lines

Other premium Japanese, Korean, or high-end Chinese grooming shear manufacturers

Brand listing is representative — factory geometry is identified per shear, not assumed by brand.

Each shear is individually evaluated and serviced using a disciplined, factory-aware process designed for convex edge preservation:

Complete shear disassembly

Thorough cleaning of all components

Detailed inspection of edge geometry, pivot condition, and hardware

Replacement of worn washers or hardware as required

Precision convex edge sharpening to restore original factory angle (unless otherwise specified)

Re-establishment of the factory ridgeline (inside face), when applicable

Reassembly

Precision tension setting

Final test cutting with no lateral pressure (no thumb or finger bias)

This process prioritizes cut quality, edge longevity, and mechanical reliability, not speed.

1–3 week turnaround depending on shear condition and workload

Inspection-verified sharpening

Mechanical setup verified before return

14-day performance guarantee

Professional dog groomers using premium convex shears

Groomers with high-value, brand-specific grooming tools

Shops requiring maximum precision and controlled results, not volume sharpening

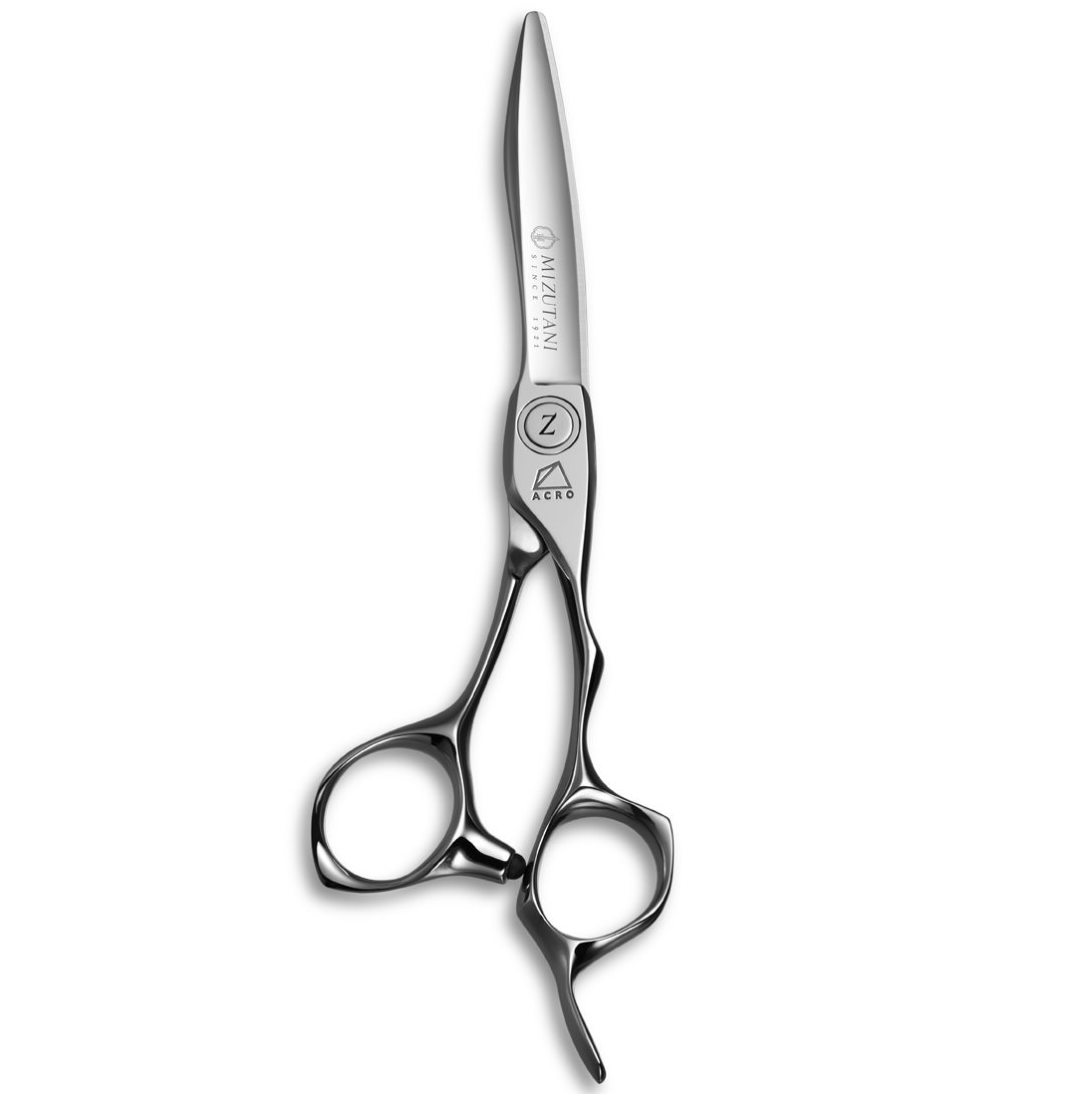

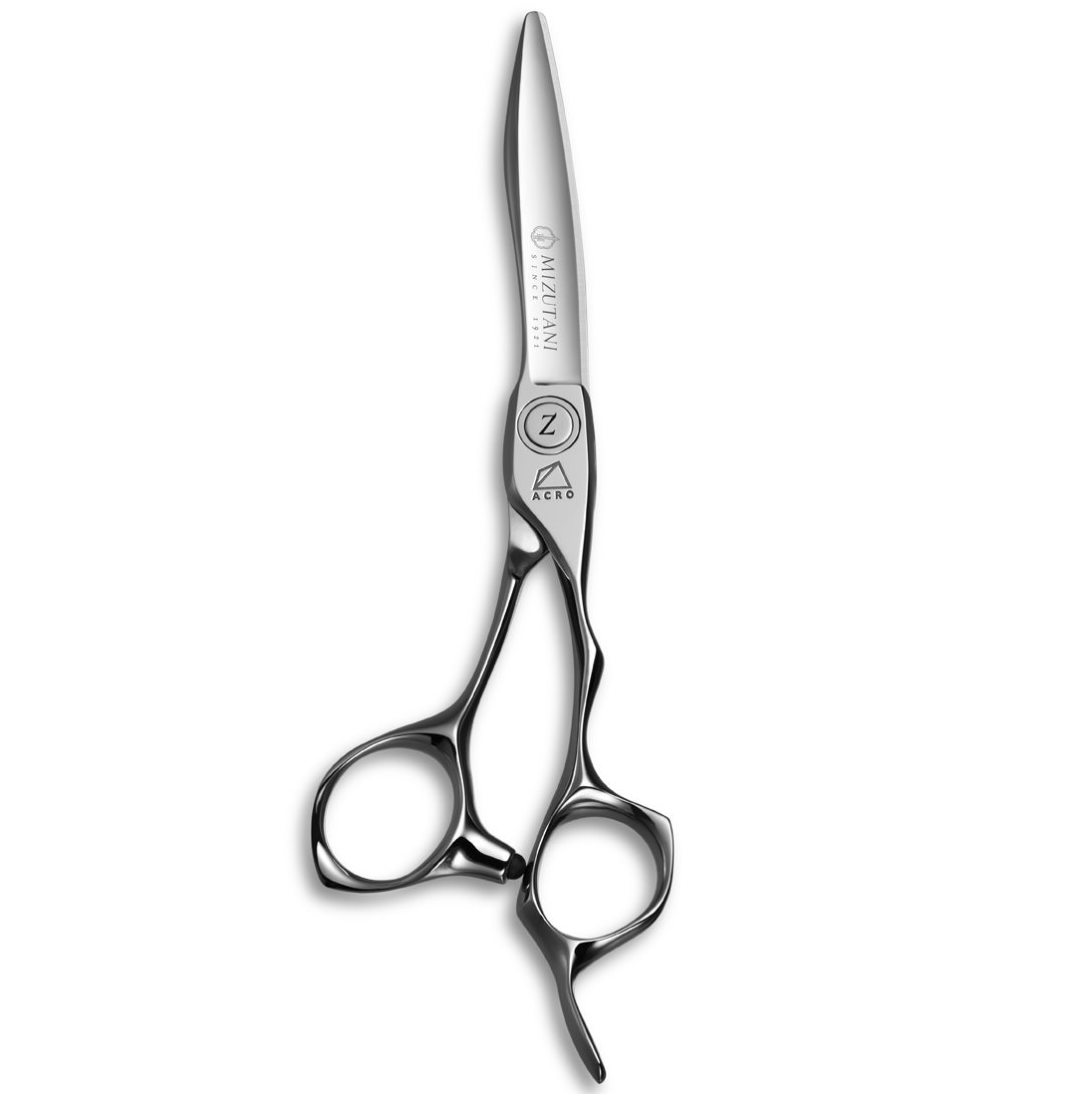

Th Z1 is produced with the sharpest cutting angle in the Mizutani line. A ” hybrid shear ” is one that can be used for dry cutting just as well as for wet cutting. The Z1 is at the top of its class when it comes to this; meaning it performs channel cutting, dry stroke cutting, and cutting blunt lines carving out the perimeter with ease. This shear comes out top 3 at demos and shear consultation appointments nationwide. It is our best ” all in one ” shear.

The latest high-tech development in scissor production uses Nano Powder (extremely small particles) and powder metallurgy to produce scissors of unprecedented strength and sharpness. While other companies claim to use ” powder ” or ” Nano Powder Metal “, it is important to ask questions such as ” where is your metal researched ” where is it sourced ” and confirm the validity of these claims. Mizutani has and always will be committed to quality over anything. You can find the information pertaining to the research it has taken as well as what Nano Powder Metal® is and is not here.

Design Note: The Z1 has a flatter blade ( compared to the Z2 ) when looking at it from the side, yet comes to a fine point when looking at it from the top. Additionally, the blade is curved for a seamless dry cutting experience.

Building Material

Nano Powder Metal®

The “PRECISIONER” model created in collaboration with Josh Lamonaca of Menspire is like an extension of your hand. The ergonomics of the thumb ring on this handle allows for an effortless back cutting experience. Created with Nano Powder Metal®, few compare when it comes to a sensationally crisp and accurate cut line.

Design Note: Take a close look at the deep groove on the thumb ring of this scissor. Handmade from start to finish, it is a one of a kind feature made possible by our factory’s best craftsman.

An all mighty precision shear.

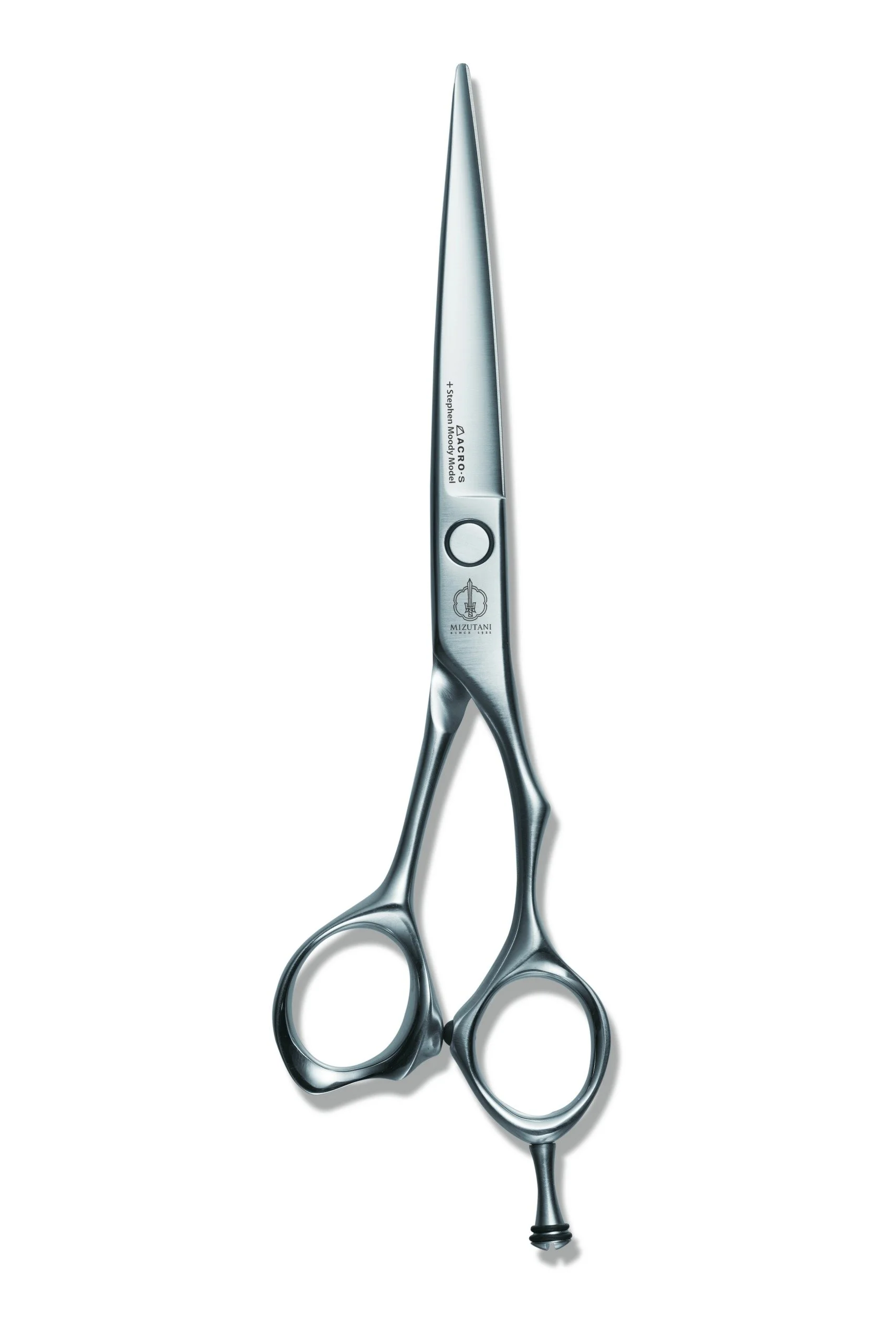

These scissors have the highest and most detailed standards for everything from the materials used, handle position, to the fitting of the blade. Aside from sleek look, it also has the added benefit of providing for a “non-slip” cutting experience. ~ designed by Stephen Moody

–

Since leaving his position as the International Executive Director of Vidal Sassoon Education in 2003, took his current position as the Director of Coty Professional Wella & OPI, and Global Education Academy Dean. Stephen’s skills have achieved international renown, and are backed by a peerless record of experience and achievements. His current position is also proof of his stature in the field. “The starting point of cutting hair, or improving your haircutting skills, is the precise handling and mastery of your scissors. “

–

Design Note:

• Blade. The blade configured for this model is that of the Penslim model.

• Handle. A slim grip handle with a semi deep contour at the thumb ring ( see photo gallery ) for the ultimate precision and back cutting experience.

Once a North American Exclusive Model, the Penslim is back and is now available worldwide. A collaboration shear between Nicole Brown based out of San Francisco and Mizutani Scissors.

–

Mizutani Scissors has been setting the standard for generations. We have always focused on the art and mastery of hand making our scissors from start to finish. And at times, we stumble upon such great inventions as the Penslim.

Established in 1921. The research and development team work in tandem with the hairdressers behind the chairs of the local cities and nations we service. One such relationship is with Nicole based out of San Francisco.

The introduction of the Penslim model has changed our precision cutting tools forever. The Penslim has an ultra thin blade created with Nano Powder Metal®. While other companies claim to use ” powder ” or ” Nano Powder Metal “, it is important to ask questions such as ” where is your metal researched ” “ where is it sourced ” and confirm the validity of these claims. Mizutani has and always will be committed to quality over anything. You can find the information pertaining to the research it has taken as well as what Nano Powder Metal® is and is not here.

–

” Penslim blade “. This is a term that is used at hair shows, education seminars, and at the booths we hold nationwide. The reason for this is that this blade has been incorporated in many of the precision cutting tools within the collection ( such as the Stephen Moody, Precisioner, etc ).

Design Note:

• The tip of these blade measure 2mm when looking at it with the tip facing you. This blade however thin, is remarkably strong and is even good as a tool for scissor over comb or carving out the perimeter at a size “6.0 ( 5.0 & “5.5 are for precision cutters ).

• This is a shear that is especially well balanced in center position and is light in weight. ( comparable to the Type K )

• The handles are wide in grip with rather large holes for both thumb and ring fingers.

Building Material

Nano Powder Metal®

SS02 vs SS01

The SS02 is the powerful of the two & the SS01 features thinner blades superior in control for precision cutting. While the swivel technology between the SS01 and SS02 are the same, the SS02 is designed with the SWORD D19 (剣型 “Kengata” blade) which is made for increased power.

Free Your Thumb

If you are a swivel user, or are experiencing hand problems, you must try this. The moment your hand grips a Mizutani Swivel thumb shear you will know it is in a class above all others. The unmatched quality of the bearing system and the truly ergonomic design of the swivel make these scissors superior to any other swivel available.

Design Note:

Double Swivel ( ” SS ” aka Speedstar )

The absolutely unique “one arm” horizontal & vertical swivel rotates through entire range of motion of the hairdressers cutting experience. Unimaginably smooth, this shear may be copied by others but never duplicated.

Right Handed 6.7 Only

*Lefty available as custom order.

Building Material

Cobalt Alloy Extramarise ll

SS01 vs SS02

The SS01 with thinner blades is superior in control for precision cutting. While the swivel technology between the SS01 and SS02 are the same, the blade of the SS01 comes to a narrow tip and are thin, which makes it ideal for use as a precision shear at “5.7in.

Free Your Thumb

If you are a swivel user, or are experiencing hand problems, you must try this. The moment your hand grips a Mizutani Swivel thumb shear you will know it is in a class above all others. The unmatched quality of the bearing system and the truly ergonomic design of the swivel make these scissors superior to any other swivel available.

Design Note:

Double Swivel ( ” SS ” aka Speedstar )

The absolutely unique “one arm” horizontal & vertical swivel rotates through entire range of motion of the hairdressers cutting experience. Unimaginably smooth, this shear may be copied by others but never duplicated.

Right Handed 6.7 - Only

*Lefty available as custom order.

Building Material

Cobalt Alloy Extramarise ll

The top selling all around workhorse shear as a double swivel. The FIT Speedstar is good for both wet and dry cutting techniques alike.

Simplicity in blade design combined with the swivel handle affords outstanding freedom of handling. The one of a kind “one arm” double swivel rotates 360° vertically, and 360° horizontally releasing both your wrist and thumb making for a full range of motion. If you are a swivel user, or are experiencing hand problems, you must try this.

Design Note: The swivel technology of this tool’s handle is unparalleled. Handmade from start to finish. Fit SS is a swivel users delight. The bearing system of this shear may be imitated by others but never replicated.

Building Material

Cobalt Alloy Extramarise l

The Axis Series Curved Shear is designed for controlled flow—allowing the blade to follow natural form with precision, ease, and balance. This tool represents the ergonomic refinement of the Axis Series, optimized for contouring, shaping, and detailed finishing.

Forged from Japanese Takefu steel, prized for its fine grain structure, edge stability, and smooth sharpening response, this shear delivers clean, consistent cuts with exceptional longevity. A full convex edge ensures effortless performance while allowing true premium craft sharpening, preserving the blade’s geometry over years of service.

The curved profile works in harmony with an ergonomic handle design, promoting natural hand alignment and reducing strain on the wrist and forearm during extended use. Balanced weight distribution and a precision nylon glide system provide smooth, controlled action with consistent tension.

Intentional sigil markings remain integral to the design. The primary marking, Cho Ku Rei, is traditionally associated with safety, focus, and completeness—serving as a visual anchor for clarity and presence. Etched on the interior blade is Hon Sha Ze Sho Nen, symbolizing continuity across past, present, and future, and the idea that care and intention extend beyond the immediate moment.

The sigils themselves do not create effects; they represent intention. Designed by a professional sharpener and Holy Fire Reiki Master, the Axis Series Curved Shear is crafted as a conduit for precision, confidence, and calm—supporting both the quality of your work and the way it feels to perform it.

Fully serviceable and supported by our in-house premium craft sharpening, the Axis Series Curved Shear is built for refined control, longevity, and fluid motion.

The Axis Series 8" Straight Shear is designed around alignment—of hand, blade, and intention. This series represents a refined evolution in performance, comfort, and material integrity for professionals who demand precision without compromise.

Forged from Japanese Takefu steel, known for its fine grain structure, edge stability, and exceptionally smooth sharpening response, this shear delivers a clean, controlled cut with outstanding longevity. A full convex edge ensures effortless performance while allowing true premium craft sharpening, preserving blade geometry throughout the life of the tool.

An enhanced ergonomic handle design promotes natural hand positioning, reducing strain on the wrist, thumb, and forearm during extended use. Balanced weight distribution and a precision nylon glide system provide consistently smooth action and controlled tension.

Intentional sigil markings remain a defining element of the series. The primary marking, Cho Ku Rei, is traditionally associated with safety, focus, and completeness—serving here as a visual anchor for presence and clarity while working. Etched on the interior blade is Hon Sha Ze Sho Nen, a symbol often used to represent continuity across past, present, and future, and the idea that care and intention extend beyond the immediate moment.

The sigils themselves do not create effects on their own; they represent intention. Designed by a professional sharpener and Holy Fire Reiki Master, the Axis Series is built as a conduit for precision, confidence, and care—supporting both the quality of your work and the way it feels to perform it.

Fully serviceable and supported by our in-house premium craft sharpening, the Axis Series Shear is engineered for alignment, longevity, and refined control.

The Conduit Series Curved Shear is engineered for fluid motion, control, and refined finishing—ideal for contouring, blending, and precision detail work.

Forged from VG-10 Japanese stainless steel, the curved blades feature a full convex edge for smooth, effortless cuts and long-lasting sharpness. The curvature allows the hand to stay relaxed while following natural form, reducing strain and increasing accuracy. A precision-fit nylon glide system ensures consistent blade tension and a controlled, balanced feel.

Intentional sigil markings serve as visual anchors for focus and presence. The primary mark, Cho Ku Rei, is traditionally associated with safety, healing, and completeness. Etched on the interior blade is Hon Sha Ze Sho Nen, symbolizing continuity across past, present, and future. These markings do not create effects on their own—they reflect intention.

Designed by a Holy Fire Reiki Master and professional sharpener, these shears are crafted as a conduit for precision, care, and alignment—supporting both the quality of your work and the way you feel while doing it.

Fully serviceable and supported by our in-house premium craft sharpening, the Conduit Series Curved Shear is built to perform with grace—and to last.

The Conduit Series Shear is a precision instrument designed for professionals who value performance, longevity, and intentional design.

Forged from VG-10 Japanese stainless steel, these shears feature a full convex edge for effortless cutting, exceptional edge retention, and true premium craft sharpening throughout their lifetime. A precision-fit nylon glide system maintains smooth, consistent blade action and reduces fatigue during long sessions.

Subtle sigil markings serve as visual anchors for focus and presence. The primary mark, Cho Ku Rei, is traditionally associated with safety, healing, and completeness. Etched on the interior blade is Hon Sha Ze Sho Nen, a symbol often used to represent continuity across past, present, and future. These markings do not create effects on their own—they reflect intention.

As a Reiki Master trained in the Holy Fire Reiki system, I design these shears as a conduit for care, professionalism, and alignment. Whether working with people or animals, this tool is meant to support precision, presence, and confidence in your craft.

Serviceable, sharpenable, and supported by our in-house premium craft sharpening, the Conduit Series is built to perform—and to last.

These scissors were designed and developed by Leen and Bertus. Two charismatic men’s hairstylists from the world famous barber “SCHOREM” in Rotterdam, the Netherlands. The “Schorem Master” is a straight blade scissor with a durable build, best friend to any barber who likes a shear with a good weight and leans towards a freestyle method of cutting.

Design Note:

Handle. The thumb ring of this model is the second largest next to the Matelite. Hairdressers who have attended education or convention with large hands and thumb have likely come across this model at our booths. It is key to identify your preference when it comes to this detail as handles that are a right fit can play a role in career longevity ( avoid hand & wrist problems ).

The Schorem Master, upgraded with Nano Powder Metal®.

Nano Powder Metal (extremely small particles that leave for 0% impurities when looked at under a microscope ), makes this a hard metal unlike any other in the market. This latest high-tech development in scissor production uses powder metallurgy to produce scissors of unprecedented strength and sharpness. While other companies claim to use ” powder ” or ” Nano Powder Metal “, it is important to ask questions such as ” where is your metal researched ” where is it sourced ” and confirm the validity of these claims. Mizutani has and always will be committed to quality over anything. You can find the information pertaining to the research it has taken as well as what Nano Powder Metal® is and is not here.

These scissors, designed and developed in creation with Leen and Bertus ( Two charismatic men’s hairstylists from the world famous barber “SCHOREM” in Rotterdam, the Netherlands. ) have become a highly favored ” classic ” for hairdressers worldwide.

The “Schorem Master” is a straight blade scissor with a durable build, best friend to any barber whose likes a shear with a good weight and leans towards a freestyle method of cutting.

Design Note:

Handle. The thumb ring of this model is the second largest next to the Matelite. Hairdressers who have attended education or convention with large hands and thumb have likely come across this model at our booths. It is key to identify your preference when it comes to this detail as handles that are a right fit can play a role in career longevity ( avoid hand & wrist problems ).

This Mizutani Authorized Sharpening service is designed exclusively for Mizutani professional shears and is performed by a Mizutani-certified sharpener following factory-aware methods and specifications.

Mizutani shears are manufactured with brand-specific convex geometry, steel treatment, and cutting dynamics that require more than standard premium sharpening. This service focuses on accurate restoration of original factory geometry, controlled edge refinement, and verified mechanical setup — without altering the shear’s intended performance.

This is the correct service level for owners who require authorized, warranty-respecting work and do not want their Mizutani shears treated like general convex tools.

This service is intended for:

Professional barbers using Mizutani shears

Professional hair stylists and cosmetologists using Mizutani shears

Owners who require authorized, factory-aware sharpening

This service applies only to Mizutani shears.

Authorized Mizutani sharpening performed by a certified sharpener

Restoration of original factory convex geometry

Controlled edge refinement and finishing appropriate to the specific model

Proper hinge service, tension setting, and reassembly

Full cleaning and inspection of each shear

Verification for chips, burrs, alignment issues, and mechanical integrity

Clear service notes outlining work performed and any recommended repairs

All work is performed using inspection-driven, process-controlled methods — not automated or generalized sharpening systems.

Standard turnaround: 3–5 business days after receipt

Priority service: Available when scheduled in advance

If additional repairs are required, you will be contacted before work proceeds.

Mizutani-certified sharpener

Factory-aware sharpening aligned to Mizutani specifications

Inspection-based process control for consistency and risk reduction

Transparent communication and documented service notes

Trusted by professionals across grooming, barbering, and cosmetology

This service prioritizes accuracy, accountability, and repeatable results over speed or volume.

Pack shears securely and include contact information

Note any service preferences or concerns

Indicate standard or priority turnaround

Ship to Battle Born Blade Sharpening

You will be contacted if any additional repair work is recommended prior to completion.

$60.00 per Mizutani shear

(Authorized factory-aware sharpening · mail-in service)

Additional repairs (pivot work, deep chip removal, recoating) are quoted after inspection.

Ship or bring your Mizutani shears to Battle Born Blade Sharpening for authorized, factory-aware service performed with precision and accountability.

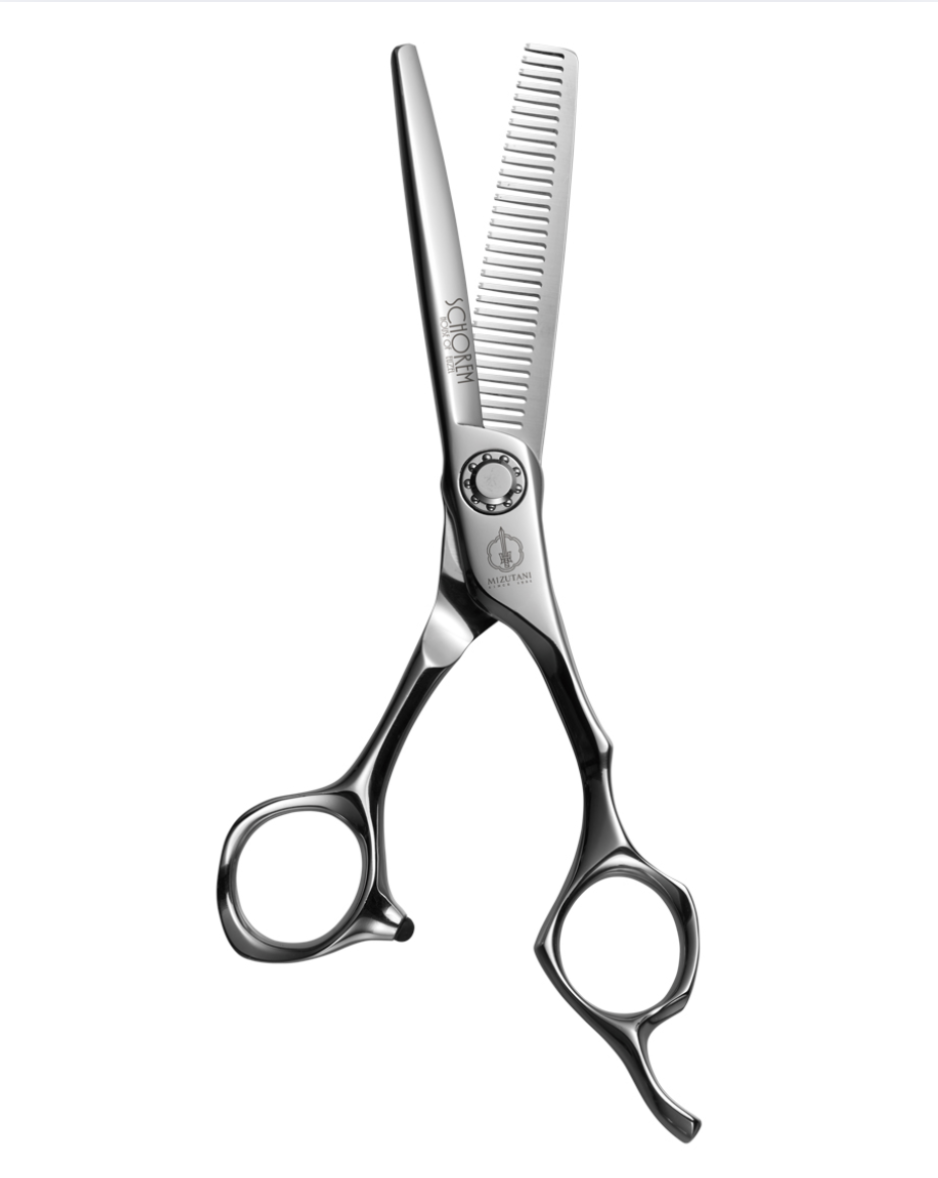

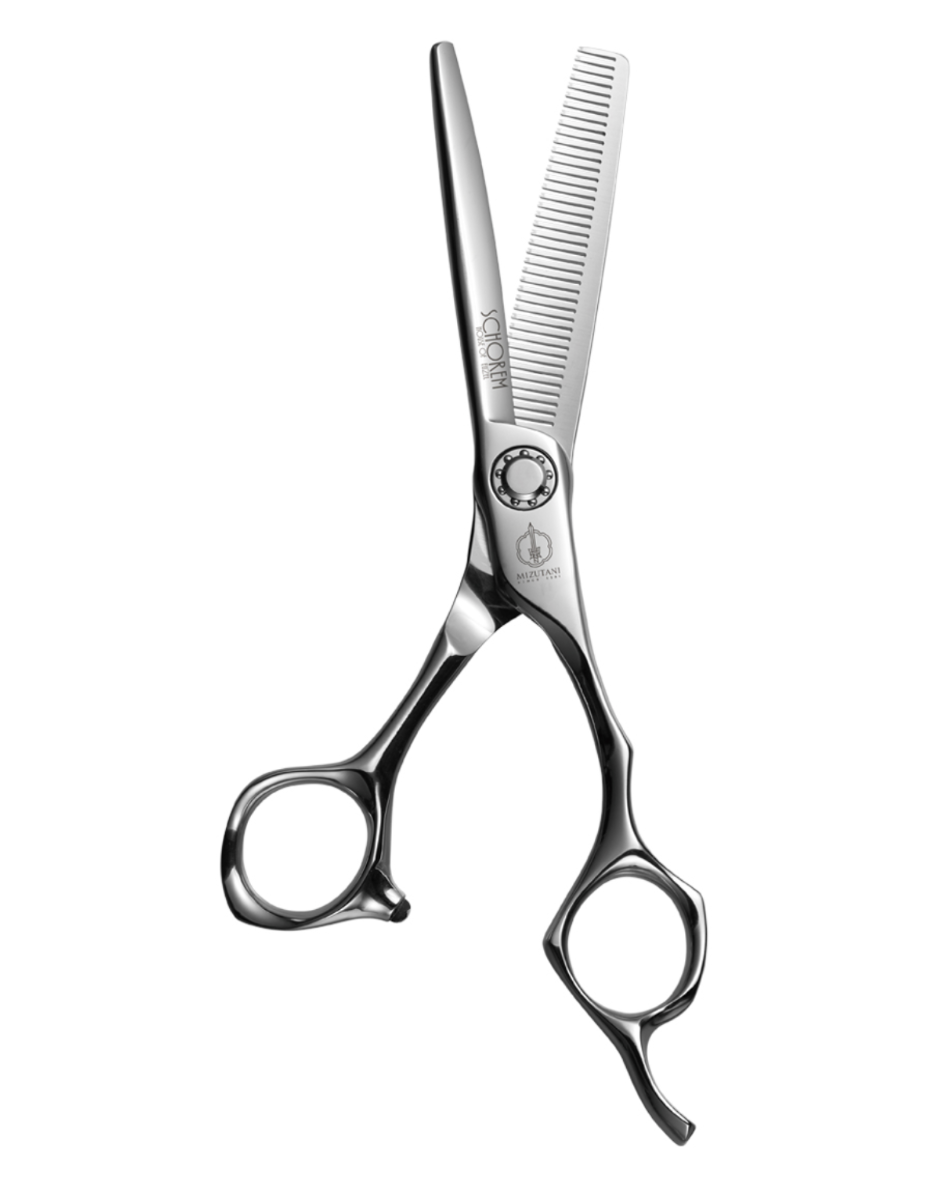

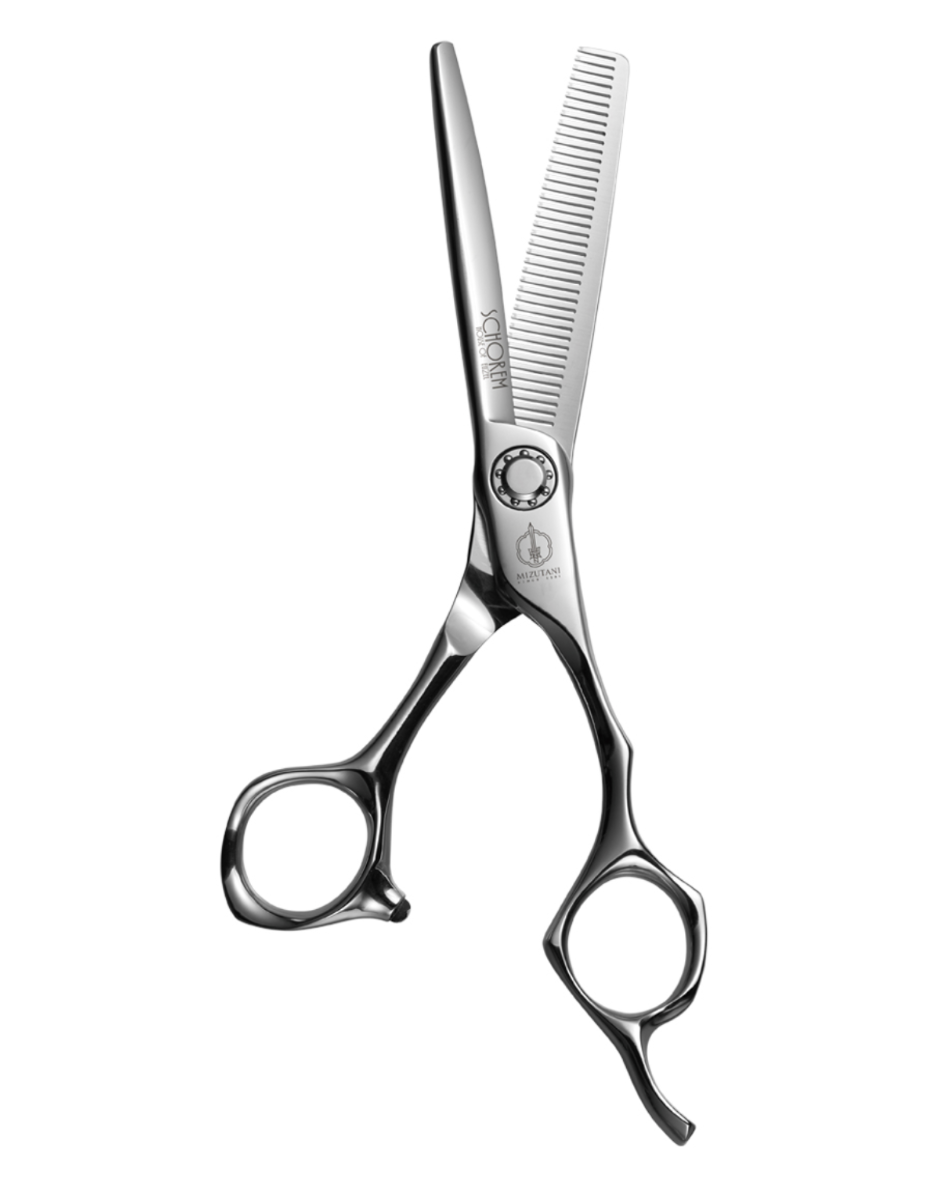

Schorem Master Blender 30

This model, when compared to the original Master Blender is compact ( features a shorter blade ). A modification made by popular demand. The Master Blender 30 is also made with a ball bearing screw.

These scissors were designed and developed by Leen and Bertus. Two charismatic men’s hairstylists from the world famous barber “SCHOREM” in Rotterdam, the Netherlands. The “Schorem Master Blender” has been perfected at the Mizutani Head Factory after many improvements made in cooperation with Mizutani’s development team. Master Blender 30 is the newest release from the Schorem series.

Design Note:

Combed teeth reverse configuration. ” Reverse “ refers to the side that the blending teeth are located on the shears. When you put the scissor face up on a table, you will find that the teeth are further away from you. The reason for this is to optimize functionality while performing the ” scissor over comb ” technique frequently used in mens grooming. The blade with the combed teeth are situated ” reverse ” so that you can get closer to the nape or areas to refine much easier than with traditional thinning shears. This is especially true with the Master Blender 30 as it features an compact blade length for increased accuracy in blending.

Building Material

Cobalt Alloy Extramarise ll

A reverse configuration shear with a 30 – 50% cut ratio. A high ranking choice for a weight removal tool.

These scissors were designed and developed by Leen and Bertus. Two charismatic men’s hairstylists from the world famous barber “SCHOREM” in Rotterdam, the Netherlands.

Design Note:

• The Master 40 is slightly longer in comparison to the original Master Blender. ( They are not to be considered a ” blender ” due to it’s high cut ratio ).

• Combed teeth reverse configuration. ” Reverse “ refers to the side that the teeth are located on the shears. When you put the scissor face up on a table, you will find that the teeth are further away from you. On the moving blade instead of still. The reason for this is to optimize functionality while performing the ” scissor over comb ” technique frequently used in mens grooming.

Building Material

Cobalt Alloy Extramarise ll

These scissors were designed and developed by Leen and Bertus. Two charismatic men’s hairstylists from the world famous barber “SCHOREM” in Rotterdam, the Netherlands. The “Schorem Master Blender” has been perfected at the Mizutani Head Factory after many improvements made in cooperation with the Mizutani’s development team.

Design Note:

Combed teeth reverse configuration. ” Reverse “ refers to the side that the blending teeth are located on the shears. When you put the scissor face up on a table, you will find that the teeth are further away from you. On the moving blade instead of still ( see scissor anatomy chart in product gallery for a visual) blade. The reason for this is to optimize functionality while performing the ” scissor over comb ” technique frequently used in mens grooming. The blade with the combed teeth are situated ” reverse ” so that you can get closer to the nape or areas to refine much easier than with traditional thinning shears.

Cutting Ratio: 25% / 33 teeth

Flat screw that can be adjusted from the back

Fixed finger rest/tang

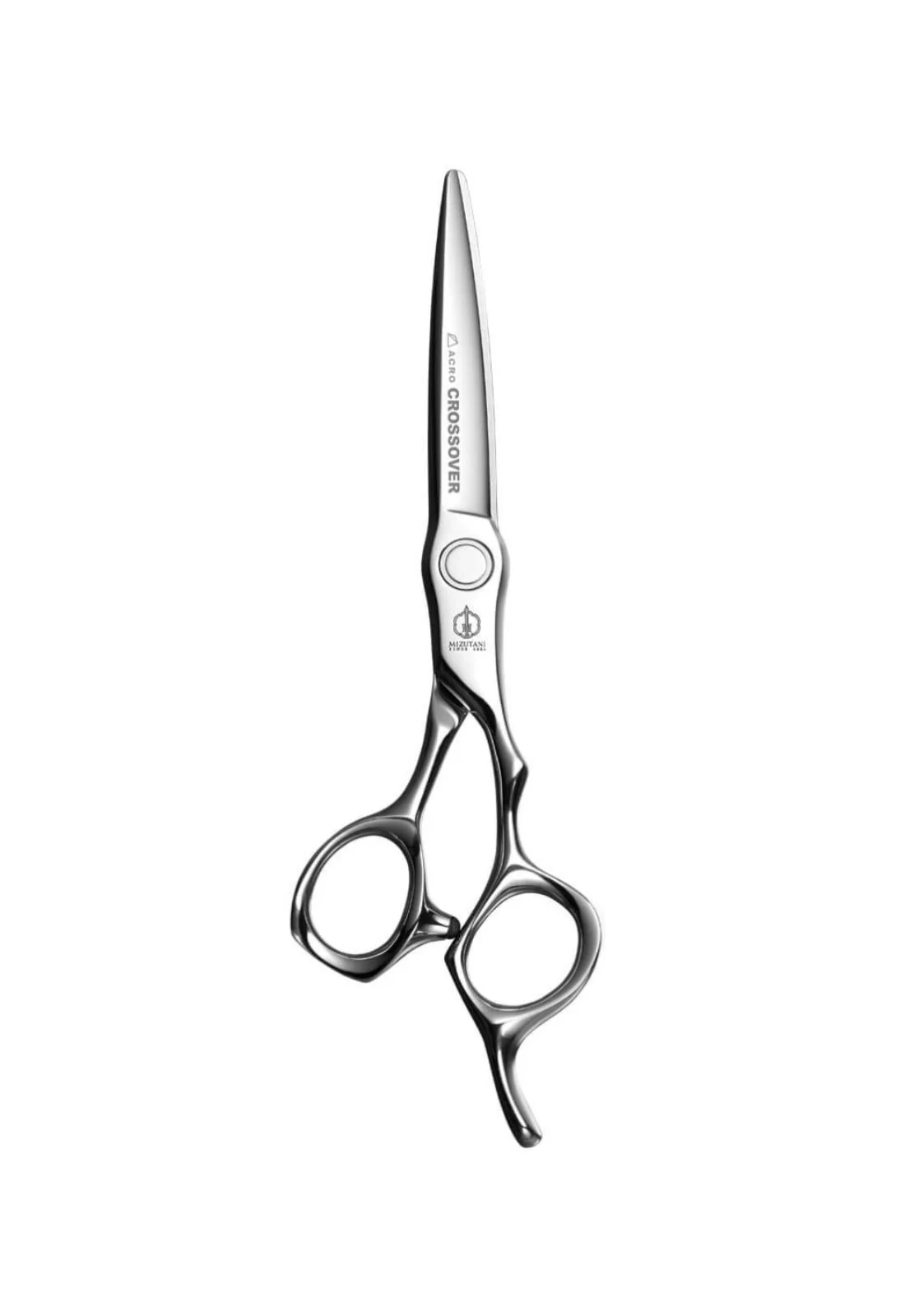

A shear made in collaboration with Whitney Vermeer.

The Crossover has been created for both blunt as well as dry cutting, and is a “Crossover” tool in that it’s design is compatible for all hairdressers whether barber or stylist.

Design Note:

• Handle. The CR1 has a wider grip handle, while the CR2 features a slim grip for people who have smaller hands.

• Handle. The CR2 features a slim grip for people who have smaller hands, while the CR1 has a wider grip handle. ( CR2 has been more popular amongst ladies and hairdressers with smaller hands especially at “5.7in. The CR1, has been favored by those with large hands ).

• Blade. Blade as you can see from looking from top has a slight curve to it ( this blade type allows for seamless dry cutting ).

• Weight of the blade. Important when considering the type of work you want to do with a cutting tool. These blades are heavier, resulting in an unmistakably straight line when cutting wet hair even with the blade curvature as an element to it’s performance.

• Total composition. The handle configuration enables power ( angle of offset on handle ), combined with the weight of the blade results in a unmistakably straight line when cutting wet hair.

Building Material

Nano Powder Metal®

This service is a standardized mechanical maintenance procedure for professional clipper machines.

Machine housing opened

New blade drive installed (typical retail value ~$12)

New hinge installed (typical retail value ~$15–$20)

Proper reassembly and operational check

Every clipper receives a new blade drive and a new hinge. No exceptions. Ols parts may or may not be included in the return shipment.

Nothing beyond reassembly

No motor, electrical, switch, or cord repair

No additional parts replaced unless explicitly authorized in advance

If parts are needed for an authorized repair, it could delay return times an additional 14 days.

If other issues are identified that require additional parts or labor, the customer will be contacted for approval before any work is performed.

In most cases, no additional work is required.

At times this may be used as a line item to bill for work performed on other brand clippers to perform other labor or parts.

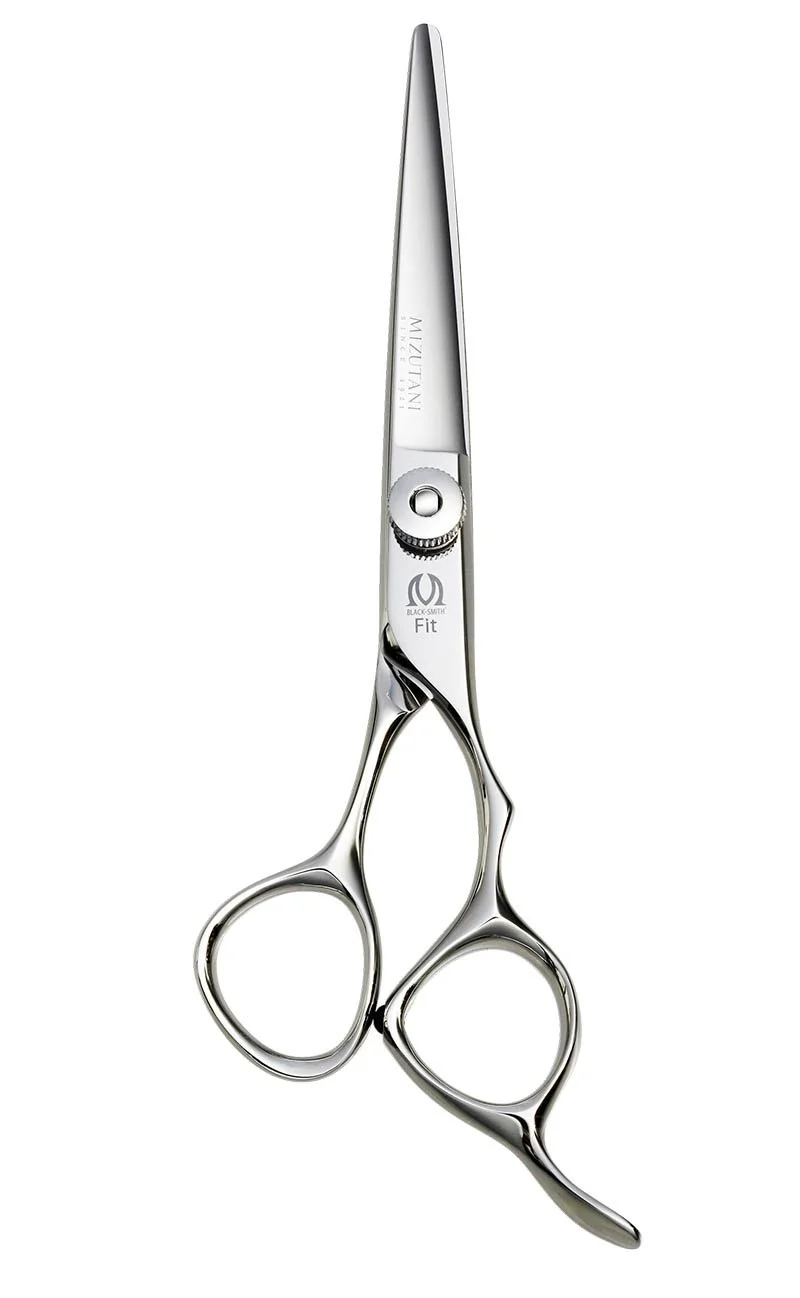

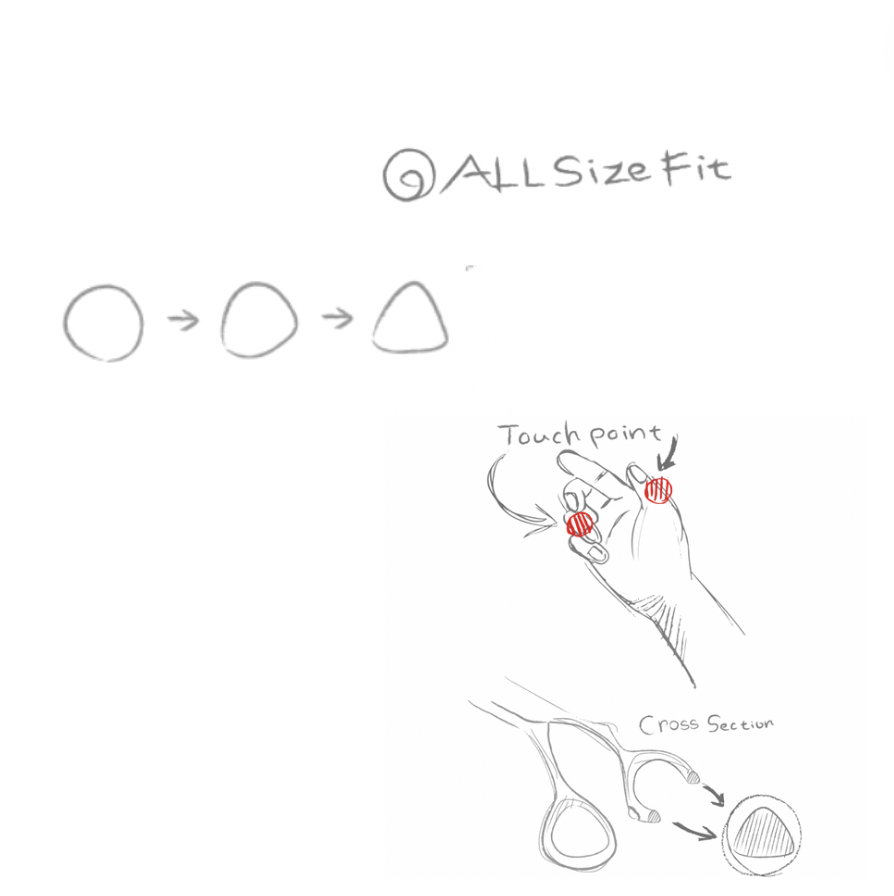

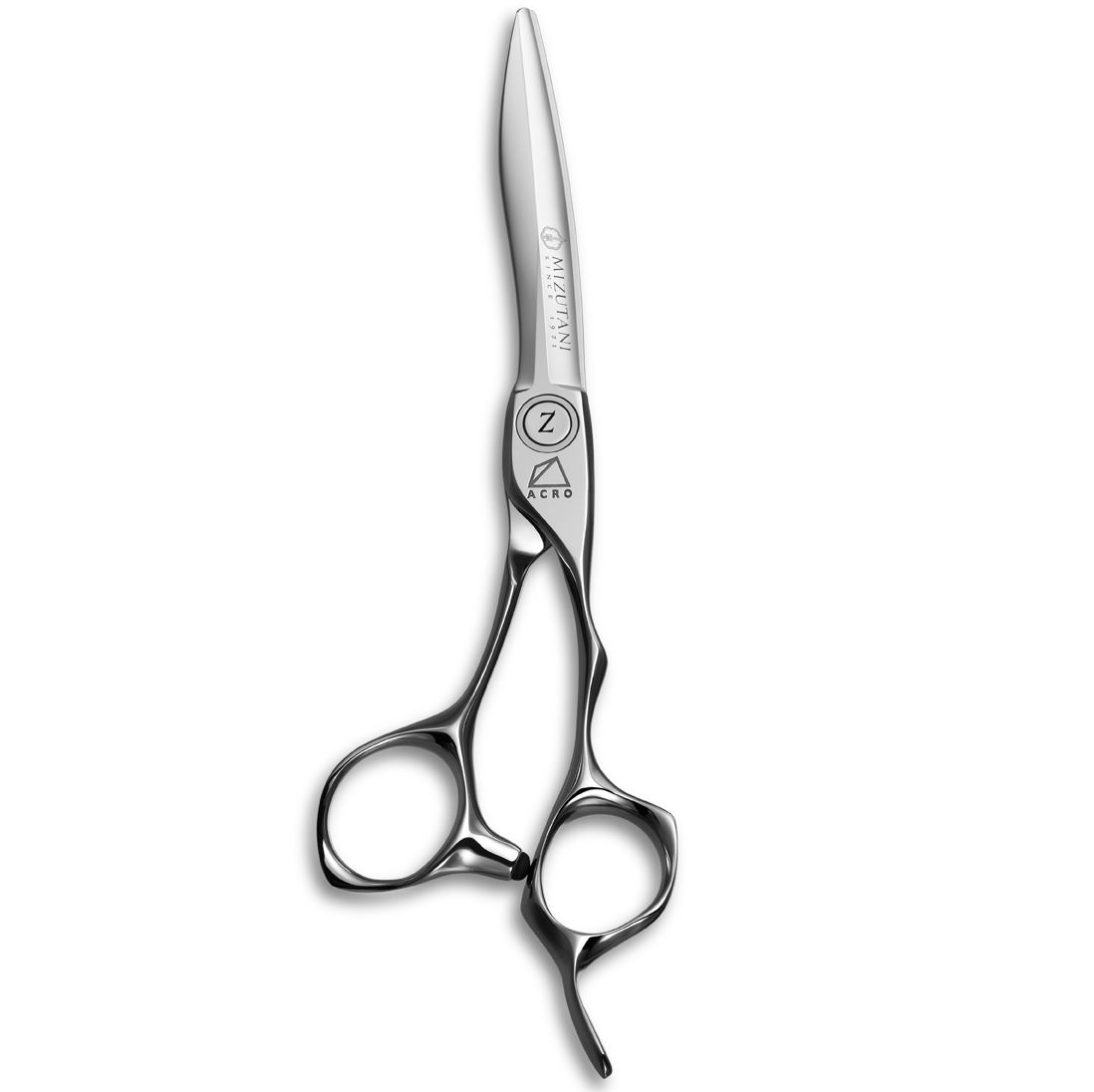

An all around tool for everyone’s kit. This innovative scissor design features a triangular and angled finger hole that fits almost any hand. Made with our classic Hamaguri edge, the Black-Smith fit can be described as simplicity and versatility in one. This shear is an easy to use classic that cuts with that true “buttery” feel that is the standard for all Mizutani scissors. It’s the best of the best when it comes to an all-arounder. So much so, that the Fit has served as the base model for many of the shears that we provide for hair school’s and academies in North America including Paul Mitchell and American Crew.

Design Note: Both thumb and ring finger holes are a triangular shape. ( See photo gallery for a visual ). Making for a most adaptable handle when coming from a different brand of shears. ( Typically ” cast “made, not hand made ). With Mizutani, the difference in craftsmanship can be felt in even the finer details such as this. This attention to detail is impossible with cast made scissors.

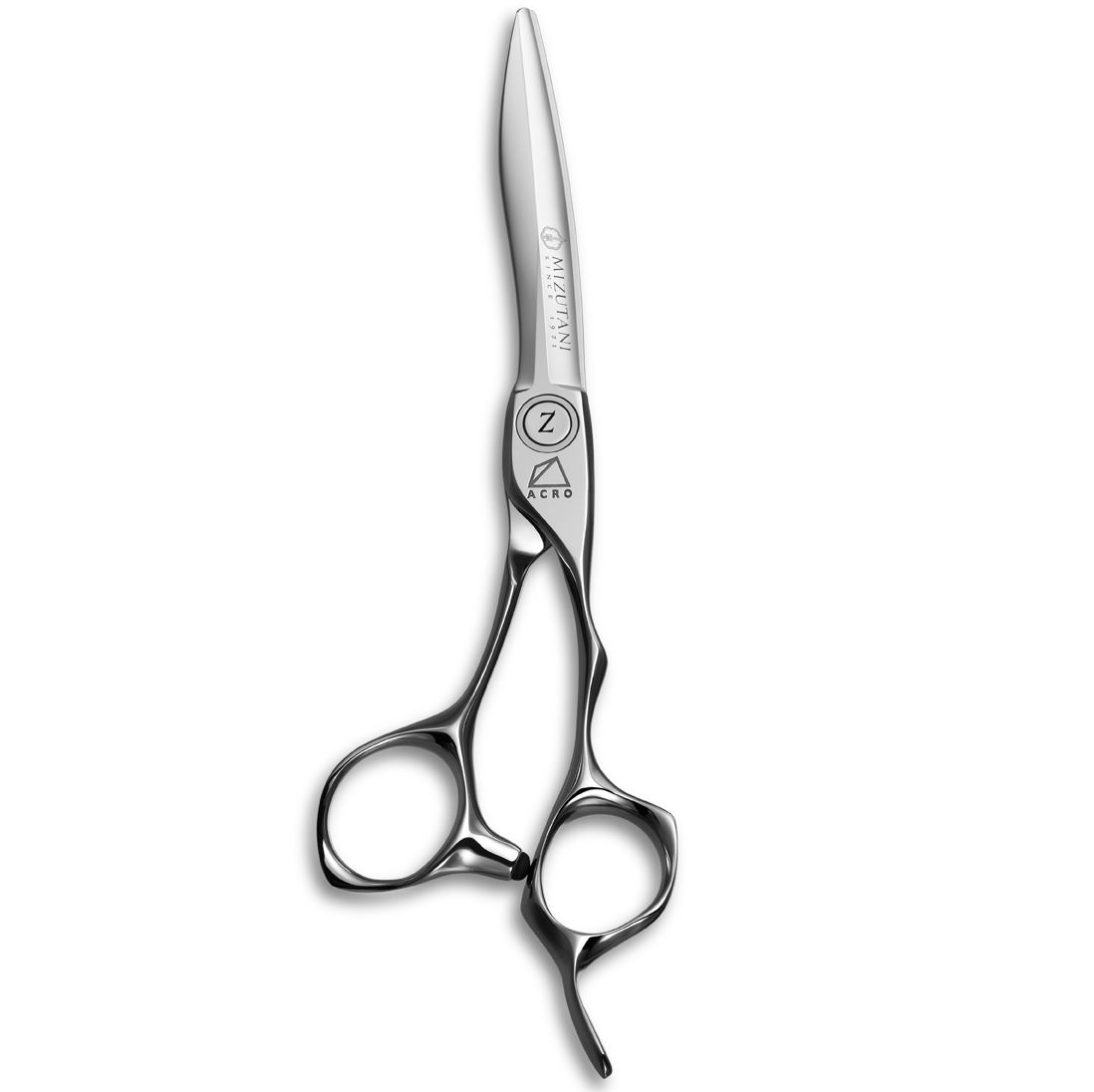

Heavier in comparison to the Z1, the center ridge is built up for power and provides a durable cutting experience. The ACRO TYPE-Z2 is crafted with a Kengata (center built up), convex blade designed to increase cutting power while providing extended blade durability.

Also created with Nano Powder Metal (extremely small particles that leave for 0% impurities when looked at under a microscope ), makes this a hard metal unlike any other in the market. This latest high-tech development in scissor production uses powder metallurgy to produce scissors of unprecedented strength and sharpness. While other companies claim to use ” powder ” or ” Nano Powder Metal “, it is important to ask questions such as ” where is your metal researched ” where is it sourced ” and confirm the validity of these claims. Mizutani has and always will be committed to quality over anything. You can find the information pertaining to the research it has taken as well as what Nano Powder Metal® is and is not here.

Design Note: The Z2 has a thicker blade ( compared to the Z1 ) when looking at it from the side. It does come to a fine point making it a good smaller size shear ( 5.5 & “6.0 ), yet this model is designed to be a blunt power tool and is favored amongst hairdressers who prefer longer blades. The blade like the Z1 is curved, making it a hybrid shear worth considering. Z2 lovers tend to work on coarse thick hair, Z1 users mainly cut using smaller sections with a style that screams pinpoint accuracy.

Building Material

Nano Powder Metal®

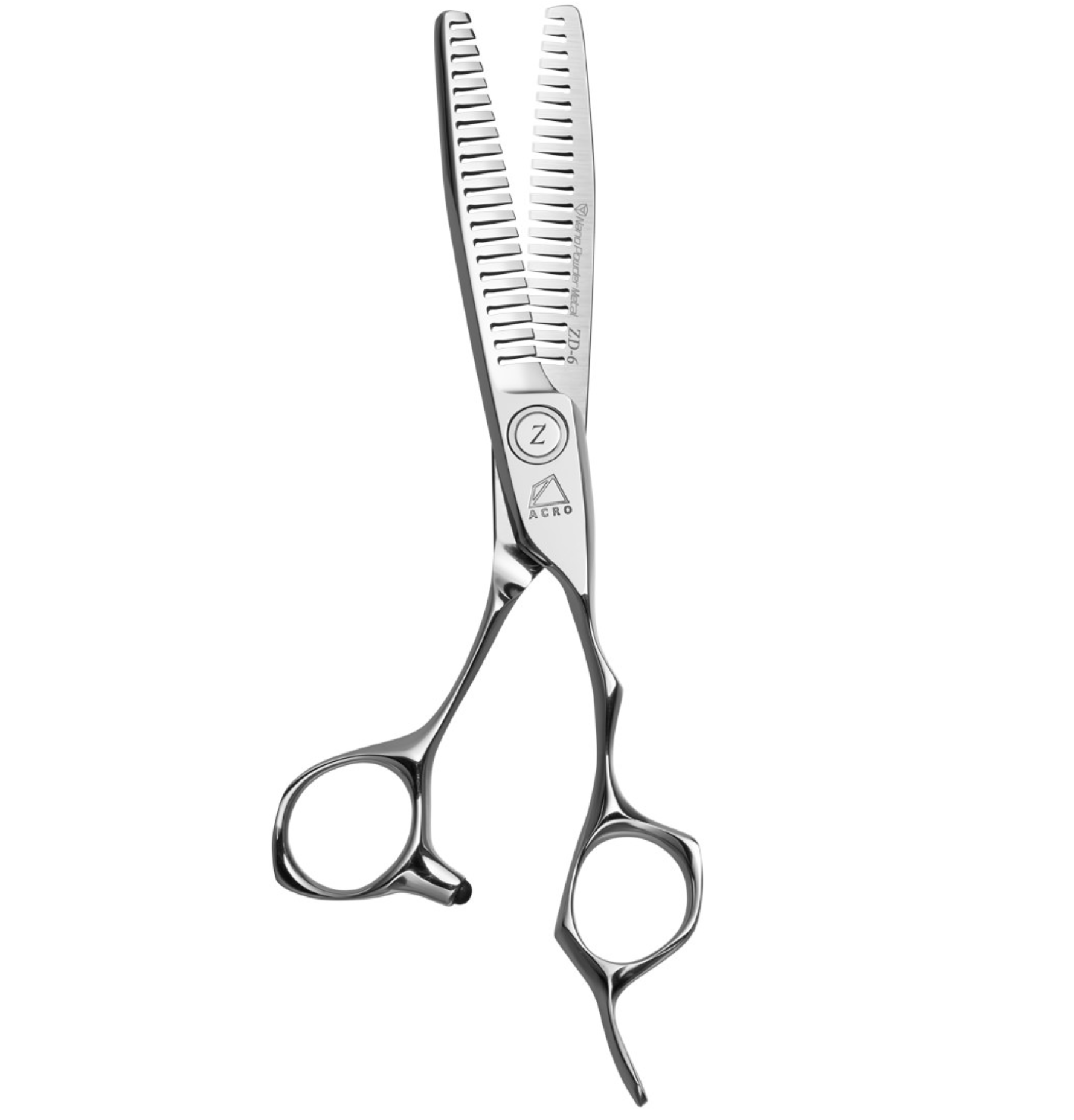

Second generation Dual Blades with Nano Powder Metal. The ZD series have teeth on both the still and moving blade. This design feature makes it easier to refine cuts using scissor over comb or even better, cutting sections of hair wet without risking observable cut lines for textured hairstyles. Having teeth on both blades will give you inner and outer texture, more movement and a more distinguished look.

ZD3 - Opposing Handle

10-15% cutting ratio

Even handle

ZD4 - Offset Handle

10-15% cutting ratio

Semi Offset Handle

ZD5 - Opposing Handle

Cut Ratio 20-30%

Even Handle

ZD6 - Offset Handle

Cut Ratio 20-30%

Semi Offset Handle

• Handle: Offset

• Blade: Regular Curve

• Pet Fur: All

• Craftsmanship: Handcrafted

• Steel: TAKEFU VG10/ZDF AG16 Cobalt (or equivalent)

• Hardness: 60-61

• Tension: Japan NMB or equivalent

• Origin: PRC

The name ABOVE comes from our mission to provide quality shears that are above, and beyond the rest. Forged with pride and precision, Above shears are handcrafted by highly skilled shear masters from proprietary cobalt steel and customized ball-bearing system. The Above team combines decades of expert experience in designing and manufacturing well recognized high-end shears for stylists, hairdressers, barbers, and groomers in the community. Above prides itself on creative designing and first-class manufacturing process, and invites you to join this journey of excellence in craftsmanship.

-

One size does not fit all. Shears come in a variety of sizes from 5 to 7 inches to fit different needs of the clients. It is common to see stylists working with multiple sizes of shears for different cutting techniques. The shorter length is ideal for precision cutting techniques and longer length is best for layer cutting techniques.

Know you Hands:

Buying a pair of shears is like buying a pair of shoes. First you need to know your size. In general, the size of your hand is the size of the shears. To ensure optimal cutting experience, most shears should not extend over your palm.

Touching Points:

Every single pair of ABOVE shears has 4 main touch-points:

-Point where the thumb touches the static handle.

-Point where the ring finger touches the dynamic handle.

-Point where the little finger touches finger rest.

-Point where the first and middle finger touch the shank of static handle.

There are 5 key elements to choose a right shear. It looks right. It weighs right. It fits right. It cuts right. It is priced right

Little Finger Matters

In comparison, females tend to have shorter little fingers than males. So shears have to be chosen accordingly, and attention should be paid to shears’ finger rest. Broadly speaking, the shorter the little finger is, the longer and wider the finger rest should be.

PALM and Fist

Offset is where the thumb is at its most natural position. Palm’s width determines shears’ offset, especially for hairdressers who like palm the shear with a fist. The right pair of shears should fit the users’ hand ergonomically and the wrong choice of shears can lead to serious long-term damage to the users’ hand like carpal tunnel and tendonitis.

Handle: Offset

• Tooth: 19T

• Pet Fur: All

• Craftsmanship: Handcrafted

• Steel: TAKEFU VG10/ZDF AG16 Cobalt (or equivalent)

• Hardness: 60-61

• Tension: Japan NMB or equivalent

• Origin: PRC

The name ABOVE comes from our mission to provide quality shears that are above, and beyond the rest. Forged with pride and precision, Above shears are handcrafted by highly skilled shear masters from proprietary cobalt steel and customized ball-bearing system. The Above team combines decades of expert experience in designing and manufacturing well recognized high-end shears for stylists, hairdressers, barbers, and groomers in the community. Above prides itself on creative designing and first-class manufacturing process, and invites you to join this journey of excellence in craftsmanship.

-

One size does not fit all. Shears come in a variety of sizes from 5 to 7 inches to fit different needs of the clients. It is common to see stylists working with multiple sizes of shears for different cutting techniques. The shorter length is ideal for precision cutting techniques and longer length is best for layer cutting techniques.

Know you Hands:

Buying a pair of shears is like buying a pair of shoes. First you need to know your size. In general, the size of your hand is the size of the shears. To ensure optimal cutting experience, most shears should not extend over your palm.

Touching Points:

Every single pair of ABOVE shears has 4 main touch-points:

-Point where the thumb touches the static handle.

-Point where the ring finger touches the dynamic handle.

-Point where the little finger touches finger rest.

-Point where the first and middle finger touch the shank of static handle.

There are 5 key elements to choose a right shear. It looks right. It weighs right. It fits right. It cuts right. It is priced right

Little Finger Matters

In comparison, females tend to have shorter little fingers than males. So shears have to be chosen accordingly, and attention should be paid to shears’ finger rest. Broadly speaking, the shorter the little finger is, the longer and wider the finger rest should be.

PALM and Fist

Offset is where the thumb is at its most natural position. Palm’s width determines shears’ offset, especially for hairdressers who like palm the shear with a fist. The right pair of shears should fit the users’ hand ergonomically and the wrong choice of shears can lead to serious long-term damage to the users’ hand like carpal tunnel and tendonitis.

Handle: Offset

• Tooth: 42T

• Size: 7″

• Pet Fur: All

• Craftsmanship: Handcrafted

• Steel: TAKEFU VG10/ZDF AG16 Cobalt (or equivalent)

• Hardness: 60-61

• Tension: Japan NMB or equivalent

• Origin: PRC

The name ABOVE comes from our mission to provide quality shears that are above, and beyond the rest. Forged with pride and precision, Above shears are handcrafted by highly skilled shear masters from proprietary cobalt steel and customized ball-bearing system. The Above team combines decades of expert experience in designing and manufacturing well recognized high-end shears for stylists, hairdressers, barbers, and groomers in the community. Above prides itself on creative designing and first-class manufacturing process, and invites you to join this journey of excellence in craftsmanship.

-

One size does not fit all. Shears come in a variety of sizes from 5 to 7 inches to fit different needs of the clients. It is common to see stylists working with multiple sizes of shears for different cutting techniques. The shorter length is ideal for precision cutting techniques and longer length is best for layer cutting techniques.

Know you Hands:

Buying a pair of shears is like buying a pair of shoes. First you need to know your size. In general, the size of your hand is the size of the shears. To ensure optimal cutting experience, most shears should not extend over your palm.

Touching Points:

Every single pair of ABOVE shears has 4 main touch-points:

-Point where the thumb touches the static handle.

-Point where the ring finger touches the dynamic handle.

-Point where the little finger touches finger rest.

-Point where the first and middle finger touch the shank of static handle.

There are 5 key elements to choose a right shear. It looks right. It weighs right. It fits right. It cuts right. It is priced right

Little Finger Matters

In comparison, females tend to have shorter little fingers than males. So shears have to be chosen accordingly, and attention should be paid to shears’ finger rest. Broadly speaking, the shorter the little finger is, the longer and wider the finger rest should be.

PALM and Fist

Offset is where the thumb is at its most natural position. Palm’s width determines shears’ offset, especially for hairdressers who like palm the shear with a fist. The right pair of shears should fit the users’ hand ergonomically and the wrong choice of shears can lead to serious long-term damage to the users’ hand like carpal tunnel and tendonitis.

Handle: Offset

• Blade: Straights

• Pet Fur: All

• Craftsmanship: Handcrafted

• Steel: TAKEFU VG10/ZDF AG16 Cobalt (or equivalent)

• Hardness: 60-61

• Tension: Japan NMB or equivalent

• Origin: PRC

The name ABOVE comes from our mission to provide quality shears that are above, and beyond the rest. Forged with pride and precision, Above shears are handcrafted by highly skilled shear masters from proprietary cobalt steel and customized ball-bearing system. The Above team combines decades of expert experience in designing and manufacturing well recognized high-end shears for stylists, hairdressers, barbers, and groomers in the community. Above prides itself on creative designing and first-class manufacturing process, and invites you to join this journey of excellence in craftsmanship.

-

One size does not fit all. Shears come in a variety of sizes from 5 to 7 inches to fit different needs of the clients. It is common to see stylists working with multiple sizes of shears for different cutting techniques. The shorter length is ideal for precision cutting techniques and longer length is best for layer cutting techniques.

Know you Hands:

Buying a pair of shears is like buying a pair of shoes. First you need to know your size. In general, the size of your hand is the size of the shears. To ensure optimal cutting experience, most shears should not extend over your palm.

Touching Points:

Every single pair of ABOVE shears has 4 main touch-points:

-Point where the thumb touches the static handle.

-Point where the ring finger touches the dynamic handle.

-Point where the little finger touches finger rest.

-Point where the first and middle finger touch the shank of static handle.

There are 5 key elements to choose a right shear. It looks right. It weighs right. It fits right. It cuts right. It is priced right

Little Finger Matters

In comparison, females tend to have shorter little fingers than males. So shears have to be chosen accordingly, and attention should be paid to shears’ finger rest. Broadly speaking, the shorter the little finger is, the longer and wider the finger rest should be.

PALM and Fist

Offset is where the thumb is at its most natural position. Palm’s width determines shears’ offset, especially for hairdressers who like palm the shear with a fist. The right pair of shears should fit the users’ hand ergonomically and the wrong choice of shears can lead to serious long-term damage to the users’ hand like carpal tunnel and tendonitis.

Handle: Offset

Blade: Cutting

Hair: Dry/Wet

Craftsmanship: Handcrafted

Steel: TAKEFU VG10/ZDF AG16 Cobalt (or equivalent)

Hardness: 60-61

Tension: Japan NMB or equivalent

Origin: PRC

And a Blender

• Handle: Off-Set

• Tooth: 35 Tooth

• Hair: Dry/Wet

• Craftsmanship: Handcrafted

• Steel: TAKEFU VG10/ZDF AG16 Cobalt (or equivalent)

• Hardness: 60-61

• Tension: Japan NMB or equivalent

• Origin: PRC

The name ABOVE comes from our mission to provide quality shears that are above, and beyond the rest. Forged with pride and precision, Above shears are handcrafted by highly skilled shear masters from proprietary cobalt steel and customized ball-bearing system. The Above team combines decades of expert experience in designing and manufacturing well recognized high-end shears for stylists, hairdressers, barbers, and groomers in the community. Above prides itself on creative designing and first-class manufacturing process, and invites you to join this journey of excellence in craftsmanship

Shop Our Blade Collection of Professional Salon Hair Cutting Shears

One size does not fit all. Shears come in a variety of sizes from 5 to 7 inches to fit different needs of the clients. It is common to see stylists working with multiple sizes of shears for different cutting techniques. The shorter length is ideal for precision cutting techniques and longer length is best for layer cutting techniques.

Know you Hands:

Buying a pair of shears is like buying a pair of shoes. First you need to know your size. In general, the size of your hand is the size of the shears. To ensure optimal cutting experience, most shears should not extend over your palm.

Touching Points:

Every single pair of ABOVE shears has 4 main touch-points:

-Point where the thumb touches the static handle.

-Point where the ring finger touches the dynamic handle.

-Point where the little finger touches finger rest.

-Point where the first and middle finger touch the shank of static handle.

There are 5 key elements to choose a right shear. It looks right. It weighs right. It fits right. It cuts right. It is priced right

Little Finger Matters

In comparison, females tend to have shorter little fingers than males. So shears have to be chosen accordingly, and attention should be paid to shears’ finger rest. Broadly speaking, the shorter the little finger is, the longer and wider the finger rest should be.

PALM and Fist

Offset is where the thumb is at its most natural position. Palm’s width determines shears’ offset, especially for hairdressers who like palm the shear with a fist. The right pair of shears should fit the users’ hand ergonomically and the wrong choice of shears can lead to serious long-term damage to the users’ hand like carpal tunnel and tendonitis.

This service is for 5-in-1 adjustable clipper blades, commonly used for detail work, finishing, and close-cut applications. These blades differ significantly from standard clipper blades and require controlled handling due to their compact construction and integrated adjustment mechanisms.

We service Wahl 5-in-1 blades as well as compatible 5-in-1 designs from other manufacturers, provided the blade is mechanically sound and within safe service limits. Each blade is inspected before sharpening to determine suitability.

Sharpening focuses on restoring cutting efficiency while maintaining proper blade alignment and function. Because 5-in-1 blades use thinner cutting surfaces and tighter tolerances, not all blades are eligible for service.

Professional inspection prior to sharpening

Precision sharpening appropriate for 5-in-1 blade geometry

Cleaning and functional testing

Return shipping included with mail-in orders

Not all 5-in-1 blades can be safely sharpened.

The following blades may be declined or returned unserviced:

Blades with excessive wear or thinning

Blades with damaged adjustment mechanisms

Blades that have been previously over-sharpened

Blades that no longer meet safe cutting tolerances

If a blade is not serviceable, you will be contacted before any work is performed.

Typical turnaround is defined by the Mail-In Sharpening system and depends on volume and condition. Transit time is not included.

Secure blades to prevent movement during shipping

Include your contact information in the package

Add this service to your Mail-In Sharpening order

Ship using your preferred carrier

Professional groomers

Mobile grooming operations

Detail and finishing work requiring adjustable blades

Severely worn or damaged blades

Cosmetic restoration requests

This service is intended for professionals who understand the limitations of 5-in-1 blades and want careful, condition-based sharpening rather than aggressive material removal.

Professional cutlery sharpening is not about making a knife “razor sharp” in isolation. True performance comes from edge geometry, steel behavior, and micron-level finishing working together. Our Mail-In Cutlery Sharpening service is designed for cooks, chefs, and serious home users who understand that a knife’s job is not to crush food—but to separate cells cleanly and efficiently.

A blade can feel sharp and still perform poorly. If the knife is too thick behind the edge, it wedges into food, tearing fibers and rupturing cells. This causes herbs to bruise, vegetables to oxidize faster, and proteins to lose moisture before they ever reach the pan.

Proper sharpening restores:

Correct edge geometry for effortless slicing

Thin, consistent bevels that reduce wedging

Low-friction surfaces that preserve texture and flavor

A clean slice preserves juices, amino acids, and aromatics—fundamental components of taste.

When a knife is sharpened correctly, it glides between cells rather than smashing through them. This minimizes:

Cellular rupture

Premature juice loss

Flavor degradation

This is why professionally sharpened knives don’t just feel better—they cook better.

Many high-end kitchen knives trace their lineage to traditional steelmaking methods that began with iron sand (satetsu) gathered from riverbeds and coastal regions. Through high-temperature smelting and careful carbon control, this process produced ultra-pure steel with exceptional edge potential.

Modern high-carbon kitchen steels—especially those used in premium Japanese cutlery—inherit this philosophy:

clean steel + controlled hardness + refined geometry = superior cutting performance.

After shaping the edge on precision stones, the final performance of a knife depends on deburring and polishing at the microscopic level.

We finish edges using ultra-fine abrasives (often in the sub-micron range) to:

Remove the wire edge cleanly

Polish the apex for reduced drag

Increase edge stability and longevity

This final step is what creates that effortless, “scary sharp” feel—where a blade slices with minimal pressure and maximum control.

Knives are precision tools, not disposable objects. Regular honing maintains alignment, but periodic professional sharpening is required to restore geometry, thin the edge, and reset performance. Our mail-in service supports this long-term rhythm of care.

1–3 Day Turnaround (after receipt)

Geometry-correct sharpening (not grinder damage)

Secure return shipping

Suitable for Western and Japanese kitchen knives

Ship your knives to professionals who understand steel, structure, and cutting physics—not just sharpness for sharpness’ sake.

Restore your cutlery to factory-plus performance and taste the difference precision makes.

Half-Day Private Session (3–5 Hours)

$500

This private sharpening consultation is a focused, one-on-one training and technical evaluation session for individuals seeking to learn professional sharpening as a disciplined craft.

The purpose of this session is education, orientation, and technical clarity—not certification, not equipment sales, and not mass instruction. It functions as an entry point into formal sharpening training, allowing serious students to understand the mechanics, standards, and realities of the trade before committing to deeper instruction or larger investments.

All authority, lineage, and professional standards governing this work are documented in the Battle Born Blade Sharpening – About page. This consultation applies those standards directly to your tools, questions, and goals.

This consultation is the required starting point for individuals considering advanced sharpening training through Battle Born Blade Sharpening.