Image 1 of 3

Image 1 of 3

Image 2 of 3

Image 2 of 3

Image 3 of 3

Image 3 of 3

Mail-In Cutlery Sharpening — Precision Edge Restoration for Serious Cooks

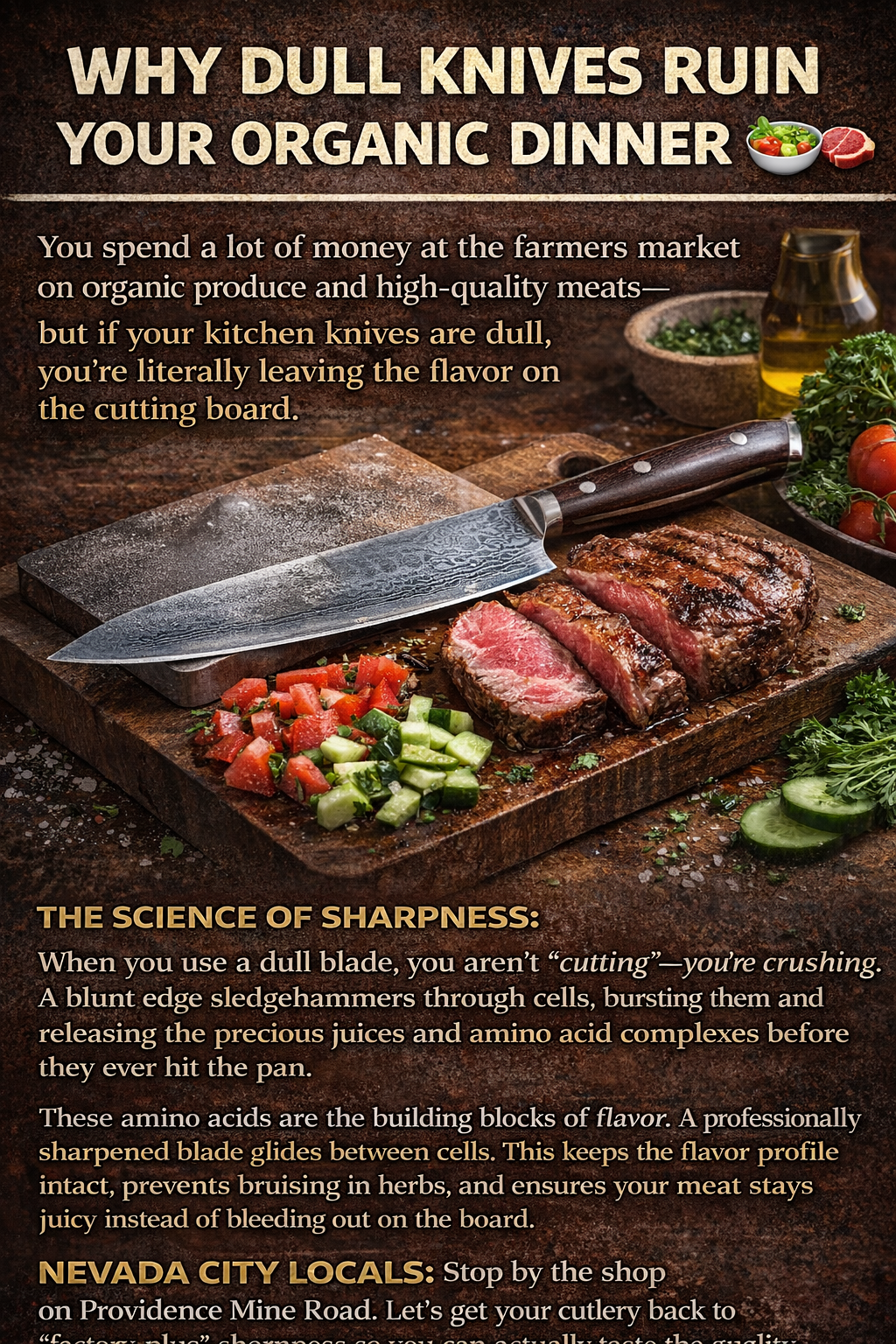

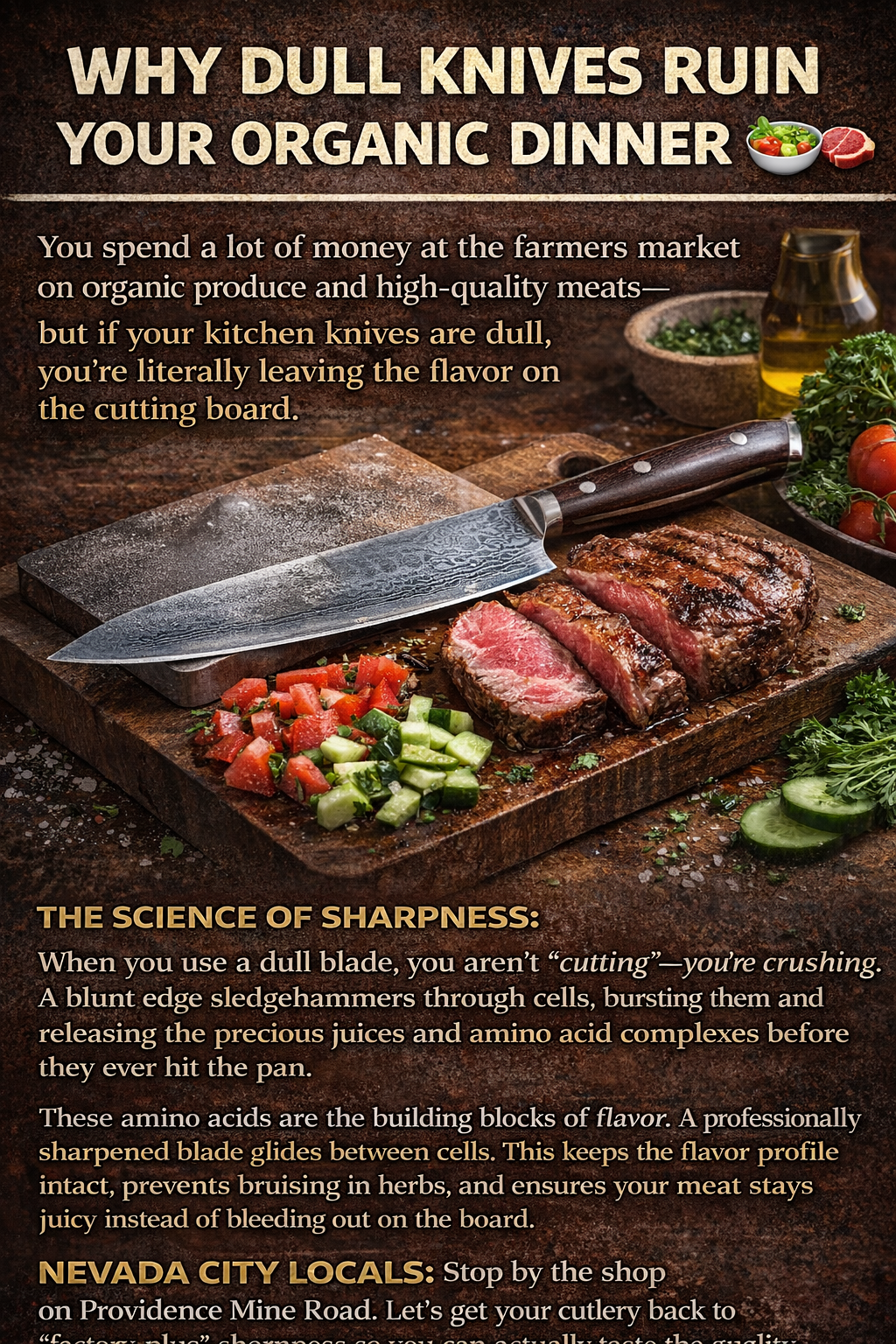

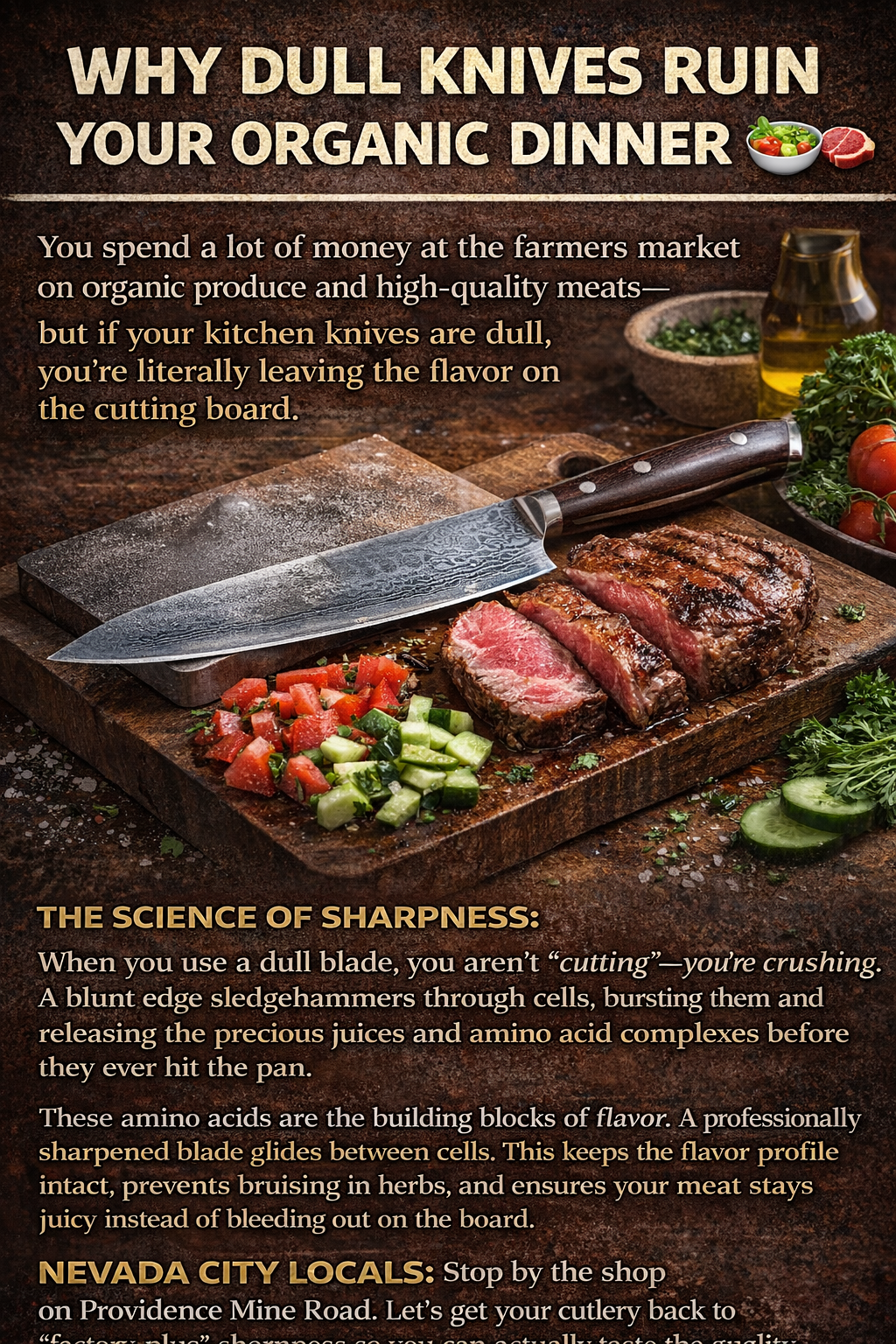

Professional cutlery sharpening is not about making a knife “razor sharp” in isolation. True performance comes from edge geometry, steel behavior, and micron-level finishing working together. Our Mail-In Cutlery Sharpening service is designed for cooks, chefs, and serious home users who understand that a knife’s job is not to crush food—but to separate cells cleanly and efficiently.

Why Sharpness Alone Is Not Enough

A blade can feel sharp and still perform poorly. If the knife is too thick behind the edge, it wedges into food, tearing fibers and rupturing cells. This causes herbs to bruise, vegetables to oxidize faster, and proteins to lose moisture before they ever reach the pan.

Proper sharpening restores:

Correct edge geometry for effortless slicing

Thin, consistent bevels that reduce wedging

Low-friction surfaces that preserve texture and flavor

A clean slice preserves juices, amino acids, and aromatics—fundamental components of taste.

The Science of Clean Cutting

When a knife is sharpened correctly, it glides between cells rather than smashing through them. This minimizes:

Cellular rupture

Premature juice loss

Flavor degradation

This is why professionally sharpened knives don’t just feel better—they cook better.

Steel Matters: From Iron Sand to Modern Kitchen Knives

Many high-end kitchen knives trace their lineage to traditional steelmaking methods that began with iron sand (satetsu) gathered from riverbeds and coastal regions. Through high-temperature smelting and careful carbon control, this process produced ultra-pure steel with exceptional edge potential.

Modern high-carbon kitchen steels—especially those used in premium Japanese cutlery—inherit this philosophy:

clean steel + controlled hardness + refined geometry = superior cutting performance.

Micron-Level Finishing & Deburring

After shaping the edge on precision stones, the final performance of a knife depends on deburring and polishing at the microscopic level.

We finish edges using ultra-fine abrasives (often in the sub-micron range) to:

Remove the wire edge cleanly

Polish the apex for reduced drag

Increase edge stability and longevity

This final step is what creates that effortless, “scary sharp” feel—where a blade slices with minimal pressure and maximum control.

A Rhythm of Care, Not a One-Time Fix

Knives are precision tools, not disposable objects. Regular honing maintains alignment, but periodic professional sharpening is required to restore geometry, thin the edge, and reset performance. Our mail-in service supports this long-term rhythm of care.

Mail-In Sharpening, Done Right

1–3 Day Turnaround (after receipt)

Geometry-correct sharpening (not grinder damage)

Secure return shipping

Suitable for Western and Japanese kitchen knives

Ship your knives to professionals who understand steel, structure, and cutting physics—not just sharpness for sharpness’ sake.

Restore your cutlery to factory-plus performance and taste the difference precision makes.

Professional cutlery sharpening is not about making a knife “razor sharp” in isolation. True performance comes from edge geometry, steel behavior, and micron-level finishing working together. Our Mail-In Cutlery Sharpening service is designed for cooks, chefs, and serious home users who understand that a knife’s job is not to crush food—but to separate cells cleanly and efficiently.

Why Sharpness Alone Is Not Enough

A blade can feel sharp and still perform poorly. If the knife is too thick behind the edge, it wedges into food, tearing fibers and rupturing cells. This causes herbs to bruise, vegetables to oxidize faster, and proteins to lose moisture before they ever reach the pan.

Proper sharpening restores:

Correct edge geometry for effortless slicing

Thin, consistent bevels that reduce wedging

Low-friction surfaces that preserve texture and flavor

A clean slice preserves juices, amino acids, and aromatics—fundamental components of taste.

The Science of Clean Cutting

When a knife is sharpened correctly, it glides between cells rather than smashing through them. This minimizes:

Cellular rupture

Premature juice loss

Flavor degradation

This is why professionally sharpened knives don’t just feel better—they cook better.

Steel Matters: From Iron Sand to Modern Kitchen Knives

Many high-end kitchen knives trace their lineage to traditional steelmaking methods that began with iron sand (satetsu) gathered from riverbeds and coastal regions. Through high-temperature smelting and careful carbon control, this process produced ultra-pure steel with exceptional edge potential.

Modern high-carbon kitchen steels—especially those used in premium Japanese cutlery—inherit this philosophy:

clean steel + controlled hardness + refined geometry = superior cutting performance.

Micron-Level Finishing & Deburring

After shaping the edge on precision stones, the final performance of a knife depends on deburring and polishing at the microscopic level.

We finish edges using ultra-fine abrasives (often in the sub-micron range) to:

Remove the wire edge cleanly

Polish the apex for reduced drag

Increase edge stability and longevity

This final step is what creates that effortless, “scary sharp” feel—where a blade slices with minimal pressure and maximum control.

A Rhythm of Care, Not a One-Time Fix

Knives are precision tools, not disposable objects. Regular honing maintains alignment, but periodic professional sharpening is required to restore geometry, thin the edge, and reset performance. Our mail-in service supports this long-term rhythm of care.

Mail-In Sharpening, Done Right

1–3 Day Turnaround (after receipt)

Geometry-correct sharpening (not grinder damage)

Secure return shipping

Suitable for Western and Japanese kitchen knives

Ship your knives to professionals who understand steel, structure, and cutting physics—not just sharpness for sharpness’ sake.

Restore your cutlery to factory-plus performance and taste the difference precision makes.