Precision Surface Integrity: The Shop Inc’s Lapping Disc Resurfacing

In the pursuit of precision sharpening, the surface beneath the blade matters as much as the blade itself. At The Shop, Inc.—a manufacturer with decades of experience in clipper blade finishing—the focus on disc surface structure underpins every claim of performance and longevity. Rather than relying on conventional lathe machining alone, their disc resurfacing process uses a precision scraping method to produce a dense, uniform surface with verified planar accuracy.

This article explains why a true surface is critical to professional sharpening outcomes, and how the resurfacing approach used by The Shop, Inc. elevates this foundational component of the sharpening system.

Why Surface Structure Matters

In sharpening systems that utilize lapping discs (especially for clipper blades), the disc surface is the interface between the abrasive and the steel. Its geometry and uniformity directly affect:

contact pattern consistency

material removal rate

wear distribution

repeatability of results

Yet not all disc surfaces are created equal. A lathe-cut pattern may look precise, but it typically leaves spiral grooves with variable depth and surface texture. These microscopic inconsistencies can cause uneven abrasive wear and unpredictable sharpening behavior over time.

The Shop, Inc.’s Scraped Surface Approach

The Shop, Inc. addresses the limitations of lathe-machined surfaces through precision scraping. According to their documentation, this process:

removes all spiral tool marks left by lathing

produces a dense, uniform surface plane

increases the useful life and consistency of the disc

Scraping maximizes structural accuracy and surface density so the abrasive medium performs consistently across the entire lapping band. This reduces weak or high/low areas that otherwise cause inconsistent blade contact and variable results.

How the Resurfaced Disc Improves Sharpening Outcomes

A true surface plane has several advantages in a controlled sharpening environment:

1. Uniform Wear Profile

Because the surface does not have engineered variances or spiral artifacts, abrasive grit breaks in evenly, creating a more predictable wear and cutting pattern.

2. Consistent Contact Pattern

An accurately resurfaced disc promotes stable blade engagement, reducing the need for compensatory technique adjustments by the technician. This is particularly important for high-precision sharpening standards where repeatability is prioritized over speed.

3. Reduced Process Variance

By eliminating unpredictable topographical anomalies introduced by lathe machining, the resurfaced disc supports process repeatability—an essential attribute when sharpening tools professionally.

A Component of a Disciplined Sharpening System

While the resurfaced disc itself is not a machine, it is a controlled surface foundation upon which professional sharpening systems rely. Its uniformity complements:

sharpening logic that demands verified contact

accuracy standards used in accredited workflows

stability in abrasive engagement and material removal

In essence, a high-integrity disc surface means fewer variables for the technician to manage and more consistent results from cycle to cycle.

Reference to Manufacturer Documentation

For those seeking formal specifications or a direct technical reference, The Shop, Inc.’s information on disc surface structure can be reviewed here:

👉 The Shop, Inc. Disc Surface Structure & Resurfacing

Their explanation of scraped versus lathe-machined surfaces provides valuable insight into why surface finish quality is foundational to professional sharpening performance.

Institutional Position

Precision in sharpening is not produced by technique alone—

it begins with the foundation that the edge rests upon.

The Shop, Inc.’s precision scraping of lapping discs exemplifies a fundamental principle of repeatable sharpening:

every interface in the process must be as uniform and accurate as the edge you intend to produce.

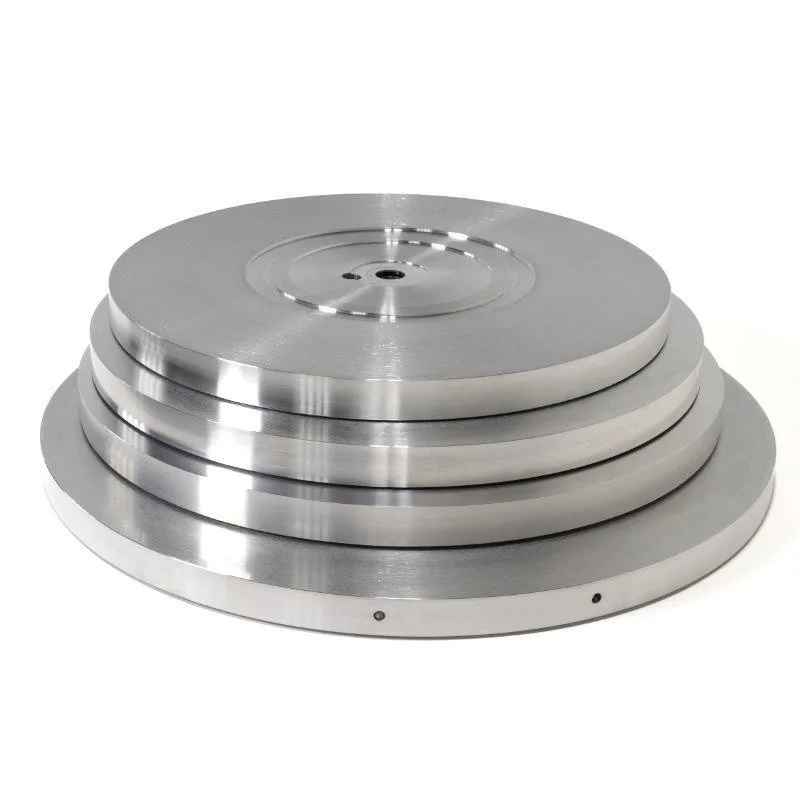

The Shop Lapping Disc Resurfacing Sizes 10”, 14”, 16” and 21”

The Shop -Precision Surface Integrity