Why Surface Integrity Matters More Than Sharpness

In professional sharpening, sharpness is often treated as the objective.

In reality, sharpness is only the visible outcome of a deeper, less obvious condition: surface integrity.

An edge can feel sharp while resting on a compromised surface.

It can cut aggressively while failing structurally.

It can perform briefly while accumulating irreversible damage.

This post explains why surface integrity—not sharpness—is the true determinant of performance, longevity, and professional reliability.

Sharpness Is a Momentary Condition

Sharpness describes how an edge feels at a specific moment in time.

It does not describe how that edge was created, how stable it is, or how it will behave under repeated use.

A tool can be made sharp:

Quickly

Aggressively

Improperly

And still leave the bench with a convincing first impression.

Professional sharpening cannot rely on impressions.

It must rely on structural truth.

What Surface Integrity Actually Means

Surface integrity refers to the condition of the interface where material removal, friction, and contact occur.

It includes:

Planarity and flatness

Contact uniformity

Friction behavior

Heat transfer characteristics

Abrasive interaction consistency

These factors govern how steel responds during sharpening and how it will perform afterward.

If the surface is unstable, uneven, or thermally compromised, the edge produced—no matter how sharp—rests on a faulty foundation.

Why Surface Errors Masquerade as Sharpness

Some of the most damaging sharpening errors produce edges that feel sharp initially.

This false sharpness is often caused by:

Localized over-removal

Inconsistent contact

Excess friction

Micro-burr formation masking instability

The result is an edge that:

Cuts aggressively at first

Dulls rapidly

Requires frequent rework

Suffers cumulative steel fatigue

Sharpness in these cases is not a sign of success — it is a symptom of imbalance.

The Hidden Cost of Ignoring Surface Integrity

When surface integrity is compromised, the consequences compound over time.

These include:

Accelerated dulling

Increased maintenance frequency

Geometry drift

Heat-induced temper loss

Permanent degradation of steel properties

None of these failures are visible at delivery.

They reveal themselves only after repeated use, when correction is no longer possible.

Professional responsibility demands prevention, not reaction.

Verification Over Appearance

Visual indicators—mirror finishes, polished bevels, aggressive bite—are not proof of correctness.

Surface integrity cannot be inferred from appearance alone.

It must be:

Controlled

Measured

Verified

Any process that prioritizes visual sharpness over verifiable surface conditions sacrifices reliability for immediacy.

In professional contexts, that tradeoff is unacceptable.

Institutional Standard

A professional sharpening process is not defined by how sharp a tool feels when it leaves the bench.

It is defined by:

The stability of the surfaces involved

The control of heat and friction

The repeatability of outcomes

The preservation of steel integrity over time

Sharpness is an outcome.

Surface integrity is the standard.

Any process that cannot protect and verify surface integrity is not a professional process—regardless of how sharp the result appears.

Surface Integrity - Measurement to ensure uniform planarity.

Surface Integrity - Magnified across a plane

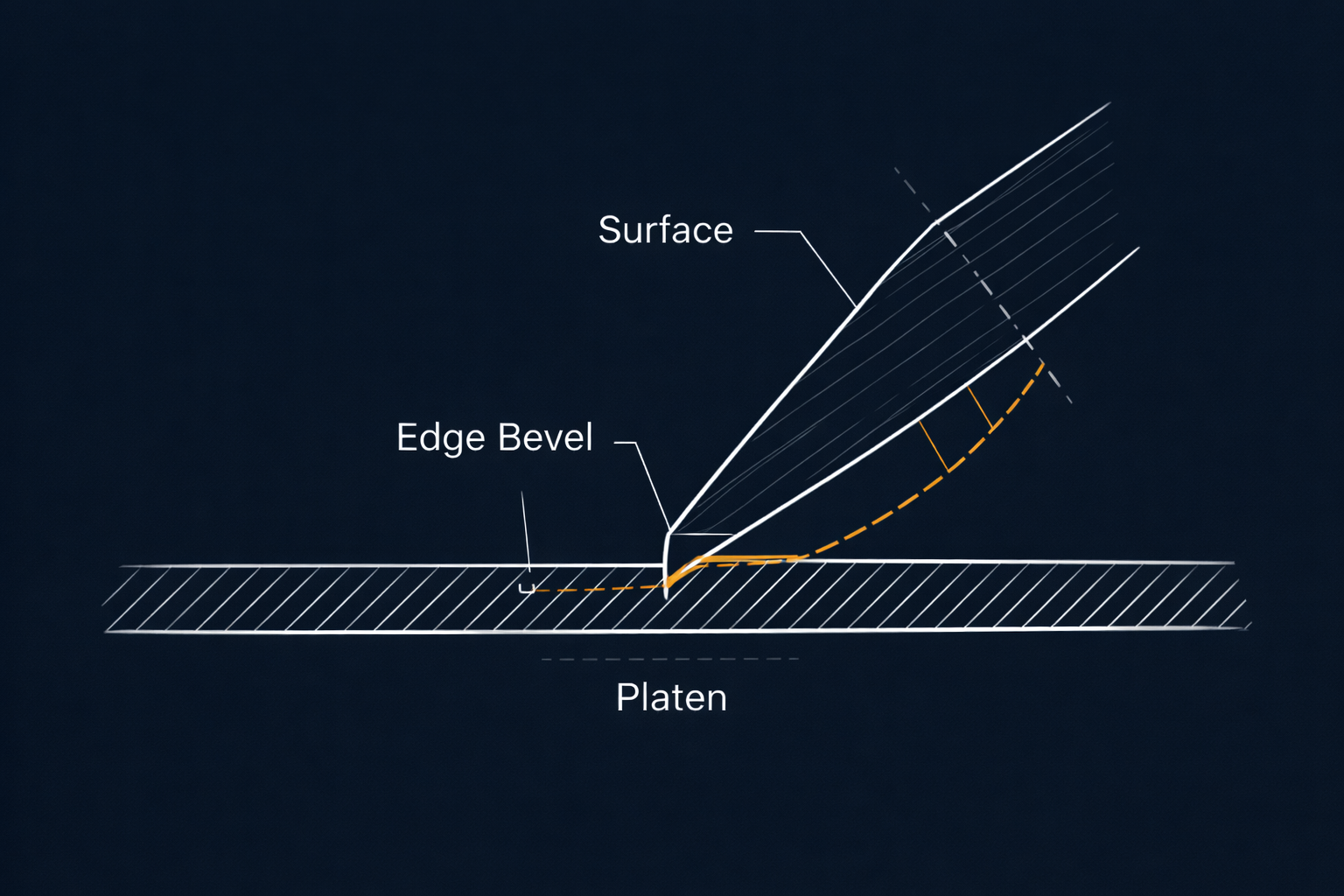

Platen dictates mirrored geometry in bevel shape